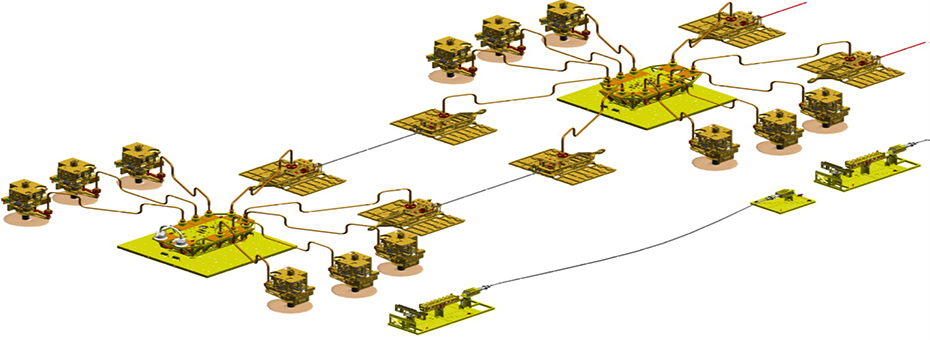

(The following case study of LPPD principles at TechnipFMC in developing a seafloor production system (illustrated above) is adapted from the book Designing the Future by authors Jim Morgan and Jeff LIker.)

One of the most dramatic stories of LPPD principles to achieve both a more efficient design and a revolutionary new way of doing business was at TechnipFMC. TechnipFMC is a global leader in energy technologies, complex engineered systems, and services in the sub-sea and gas industry. Among other things, the London-headquartered company designs and builds subsea production systems that control and commingle fluids on the seafloor at depths of up to 9,842 feet; the deepest a human has dived is nearly 2,300 feet, a world record held by the French company Compagnie Maritime d’Expertises. So in some ways these systems would be easier to install, operate and service if they were in space.

The production systems consist of enormous components, including “Christmas trees,” manifolds, value, and connectors spread out over a 30-square-kilometer on the seafloor. They must withstand crushing pressures and incredible temperatures; resist corrosion, sand, and debris; and be operated remotely with virtually no maintenance for 25 years. And they can absolutely never, ever leak—all while controlling 10,000 barrels of oil per well per day at 1,000 psi and at temperatures higher than 100 degrees F.

Oil and gas are finite resources, and as more easily trapped reservoirs are depleted, oil companies are forced to move to ever more challenging environments. Oil still provides a significant amount of the world’s energy needs, and according to TechnipFMC VP Paulo Couto, the percentage of that oil coming from the subsea is predicted to steadily increase.

The oil and gas industry faced an environment of increasingly difficult engineering challenges and ever-escalating costs. Couto, the VP of global subsea technology and engineering and based in TechnipFMC’s Brazil Technical Center in Rio de Janeiro, and his colleagues knew this pattern could not last. They had to find another way of meeting these formidable challenges other than just throwing money at them. This thinking was confirmed when oil prices plummeted from $100 per barrel to about $50.

Couto was aware that the company’s manufacturing operations had made some significant improvements with lean methods, so he started his search there. However, two things were quickly apparent: (1) the improvements in manufacturing, while impressive, would never get the company near where it needed to be, and (2) the specific methods and techniques in manufacturing would not help the company in engineering and development. So he looked further and got acquainted with lean product and process development, and he quickly tasked the members of his team to learn everything they could about it.

Senior management also was challenging the technology and engineering team to lead a companywide change in its approach to the business. So while the team in Brazil continued to learn more about and experiment with LPPD, Couto reached out to his counterparts in others parts of the world: David MacFarland, Mike Tierney, and Andy Houk, engineering leaders in Houston, Scotland, and California, respectively. Alan Labes was tagged as the first-ever chief engineer in the company, and he lead the development of Subsea 2.0, a product targeted to transform not only a company but an entire industry. Setting targets for the project was simple: half the size, half the part count, half the weight, and half the cost, which would make it the foundation of a completely new way of doing business. But there was nothing simple about achieving this challenge.

The technology and engineering team employed many LPPD tools and methods, Most prominent in developing the Subsea 2.0 were the CE, concept paper, obeya management system, set-based concurrent engineering, and trade-off curves:

Chief engineer: In addition to Labes’s role as overall program CE, a CE was assigned for each major subsystem. This approach had mixed results because the technology and engineering teach had not had time to create an environment or context for the role’s success, and subsequently there was pushback from some internal “experts” who did not understand what the team was trying to do, nor the roles and the responsibilities. Interaction with the manufacturing and marketing teams also needed to be improved. However, leadership set clear expectations for Labes and supported him and the subsystem CEs throughout the project. The technology and engineering team later declared the CE experiment was a major success and did not think the project would have been successful without it. Having full accountability for project success and a product-focused mindset was crucially important to the success of the CE.

Concept paper: Labes started with a concept paper to clarify and align around the vision for this project. He found that the first benefit was that it helped him work through his own thinking on the project, identifying holes in his logic and conflicts in his vision. He used it to better understand and communicate the urgency of the current-state situation for the company—to provide the “why.” In addition to the vision and current state, it established targets, set up the global schedule, and assigned specific design work to the various engineering centers around the world. The concept paper also helped to connect with manufacturing, which would need to change its processes dramatically for the team to hit its targets. The document also initiated some difficult-but-needed discussions across the entire team, set the scope and functional requirements and acted as a contract. This enabled Labes to move forward without last-minute, top-down changes; it created a true north for the team against which to measure its performance, and it virtually eliminated late “deviation requests” from the team.

Obeya: The team needed a level of transparency, collaboration, and fast decision making that had not seemed possible in the past, and team members agreed to visit Herman Miller in Holland, Michigan. It was an epiphany. Not only did they see the use of the obeya system in action, but they learned about how to use milestones more effectively. The members returned to Brazil fired up about employing what they learned in Michigan. The obeya system completely revolutionized the way that the team worked together. TechnipFMC also established the obeya system in the other engineering centers. According to Labes:

“When creating a new system from scratch, the tradeoffs involved in architectural decisions at the system, subsystem, and component level need to be tested extremely fast so the full spectrum of possibilities is covered. The obeya system enables not only that, but also enables a deep and common understanding for all the team members of the most valuable characteristics of the system and what they work must deliver to support it. The obeya management system improved the process dramatically—especially due to the novel nature of the project, and the many unknowns the team had to deal with and lessons that had to be learned during the development process.”

Set-based concurrent engineering (SBCE) and trade-off curves: These practices, used in conjunction with targeted, rapid prototyping, enabled the team to look at many alternatives and understand the impact of the various alternatives. With this approach, the people on the team could identify which technologies the company should invest in and what the total system would look like in various configurations. Labes and Couto describe the process:

“The process started with the CEs locking in boundaries, constraints, and variables, such as material strengths, torsion, and other mechanical properties (such as friction, tolerances, and product architecture). Then CEs conducted brainstorm sessions with cross-functional teams in order to generate different design ideas. The team then established a de-selection process where the concepts were ranked and the concepts that were proven not to work or were ranked very low were quickly eliminated, until a manageable number of concepts were left. This process continued, gradually adding more engineering effort to the remaining concepts for each subsequent de-selection round, so knowledge about the concepts was being developed and the team continually evolved their thinking. During the process it was not unusual that a new concept was created out of cross-pollination between existing concepts.”

Once the set of options was reduced to three to five, the team started to assess in detail how each concept would react to a change in one of the variables mentioned above. This was an intense process, as every option had to be computer-simulated and/or physically prototyped and its design adjusted accordingly. Out of this process, the team saw that some concepts were more sensitive to one variable than others, and they also identified which design changes would deliver the biggest benefit as well as at what point an improvement in performance would no longer deliver any value to the design. This knowledge was captured in tradeoff-curve charts that could visually communicate how each concept would have its overall design efficiency affected by the full range of the variables. The team was amazed at how well the curves communicated a complex set of technical relationships. In fact, one CE, John Calder, commented that “tradeoff curves were a simple, elegant and powerful representation of a tremendous amount of work—similar to Einstein’s E=MC2.”

This was not a short sprint. It was a long and arduous process. And the team had no idea what the outcome would be when they started the Subsea 2.0 program, composed of multiple complex development projects going on simultaneously. SBCE and tradeoff curves were central to the team’s ability to develop a disruptive system because they would not be able to do so had they not been able to fully explore the design space with these methods. The long cycles in fine tuning the design after they went to testing provided a reassurance that no matter how confident you are on the design, it’s not until fully tested that victory can be claimed and all knowledge is captured.

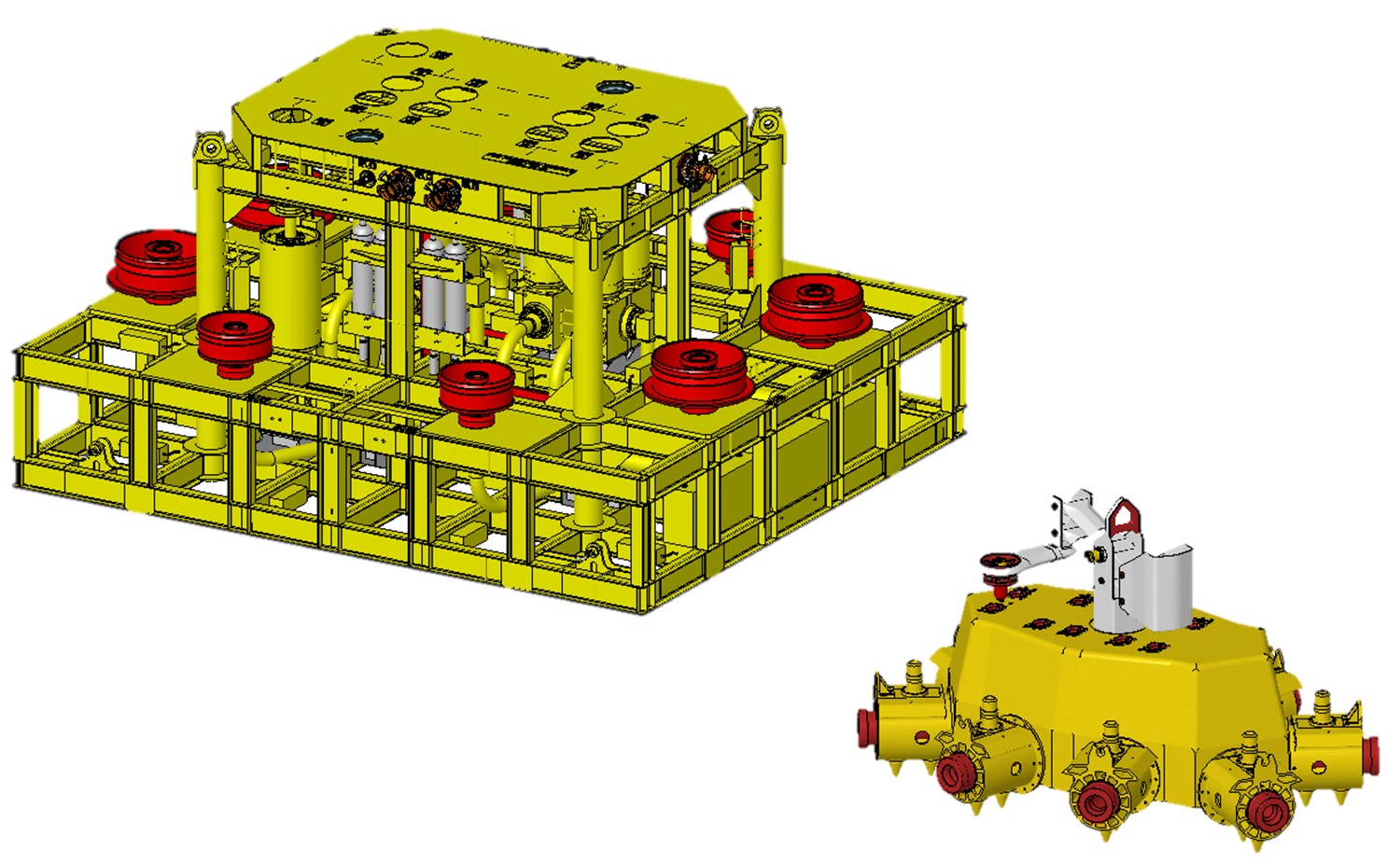

The team achieved the objectives of half the weight, half the size, and half the part count, and did so at a dramatically lower price point (see figures below for size and complexity comparisons). And it delivered the project on time, at cost, and at a projected lead-time reduction of one-third on future orders. And best of all…the teams love working this way! And now TechnipFMC is working to spread this design philosophy and approach around the global company.

Conventional subsea manifuold versus Subsea 2.0 manifold–same functionality, half the size and weight.

But there is more. Not only did the team hit its targets on time, but it created a significant competitive advantage and a new development operating system for the company. And investors and analysts have noticed. Couto presented the breakthrough product and new methodology to an outside group of analysts, and the result was an upgrade of the company stock from “hold” to “buy” and an immediate 3 percent jump in the stock price. Byron Pope, managing director of Tudor, Pickering, Holt & Co., wrote just one of many glowing reports:

“Seeing is fully believing, and we very much like what we saw (and heard) at the Analyst Day. We were treated to what was a rather compelling TechnipFMC Analyst Day in which the company illustrated how its radical rethinking of how to best help its E&P customers improve their offshore/deepwater project economics has resulted in both improved form and functionality of the company’s subsea systems offering (FTI’s “Subsea 2.0”), a harbinger of an eventual renaissance in subsea projects being sanctioned in 2018+. The essence of Subsea 2.0 and why it is the proverbial game changer?…try 50+ percent reductions in the size, weight, and number of parts associated with key subsea production systems elements (trees, manifolds, etc.). It is these sorts of innovations which heighten our confidence. Lightbulb moment of confirmation was during our rotation through the company’s Innovation & Technology Showroom (which, by the way, was our close-up…but no camera’s allowed…looksee at some of the key hardware elements of Subsea 2.0) when it came to light that TechnipFMC’s leadership challenged the organization to think differently well before the most recent oilfield service industry downtown began in earnest.”

The TechnipFMC team had, indeed, designed the future. Couto describes their experience with LPPD this way:

“LPPD was key to enabling the disruptive change we were looking for. And it is much more than love at first sight; in this case, the more we learn, the stronger the passion. We simply cannot imagine how we would work without it now.”