LEI asked the Lean Community: What are you doing to make things better? Below is the first of many great replies. Stay tuned to the Lean Post over the next few weeks and months and see more of what the lean community is doing to make things better.

Ever since the switch from paper medical records to electronic, the skill sets required for health information management (HIM) have been changing exponentially. HIM at our large academic medical center was no exception. We struggled not just to keep our staff skill-sets current in the face of change, but also to convey the value of HIM’s work to our leadership – which then presented additional obstacles in securing required resources for the department.

Ultimately I think the value of the work of HIM professionals is summarized as:

- Bridging the clinical and technical

- Improving patient care by facilitating timely, accurate and actionable patient information

- Ensuring that access to protected health information is efficient, effective and most of all, safe. In HIM we safeguard our patients’ information.

But how could we convey that value to our leadership? We had to make HIM’s value visual.

Our first step was to establish and document standard work. We sent at first just our departmental leadership (directors and managers) through a five-day lean healthcare certification course. We then created value stream maps for our key workflows, and from there measured first time quality, wait time, process time, turnaround time and were able to begin reporting basic output, volume and productivity metrics to our leadership.

For example, we mapped the process of issuing a birth certificate for a newborn (from the time the infant is born at the medical center to the time the parents receive a certified copy of their birth certificate); the process of analyzing/completing a medical record after an Emergency Department, ambulatory encounter or inpatient stay; our process for responding to physician requests for assistance at our Deficiency HelpDesk; and the process of providing research monitors access to patient medical records, to name a few.

It was an iterative process, as initially leadership was most interested in the fact that objective performance standards were being created and applied to:

- Define value for our customers (patients, other University of Michigan Health System departments)

- Identify areas for improvement

- Engage staff in the development and execution of countermeasures/experiments

- And most importantly, demonstrate measurable increases in the value of HIM services

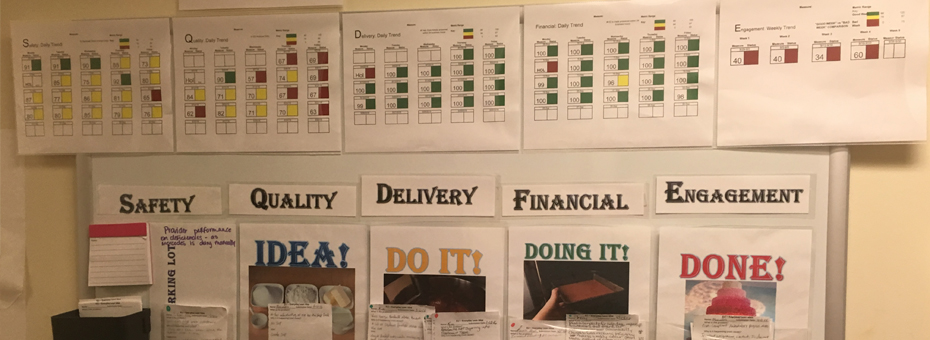

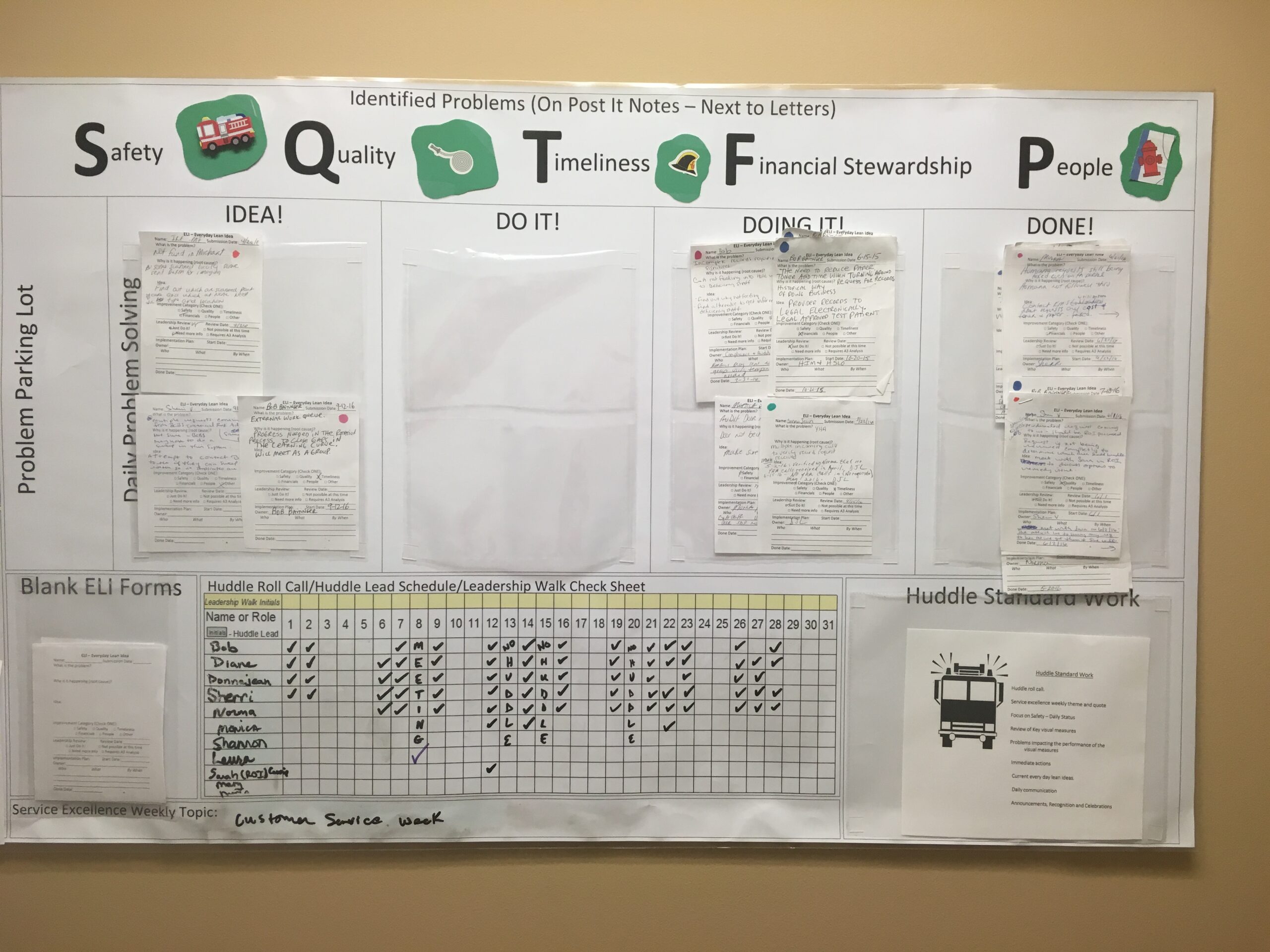

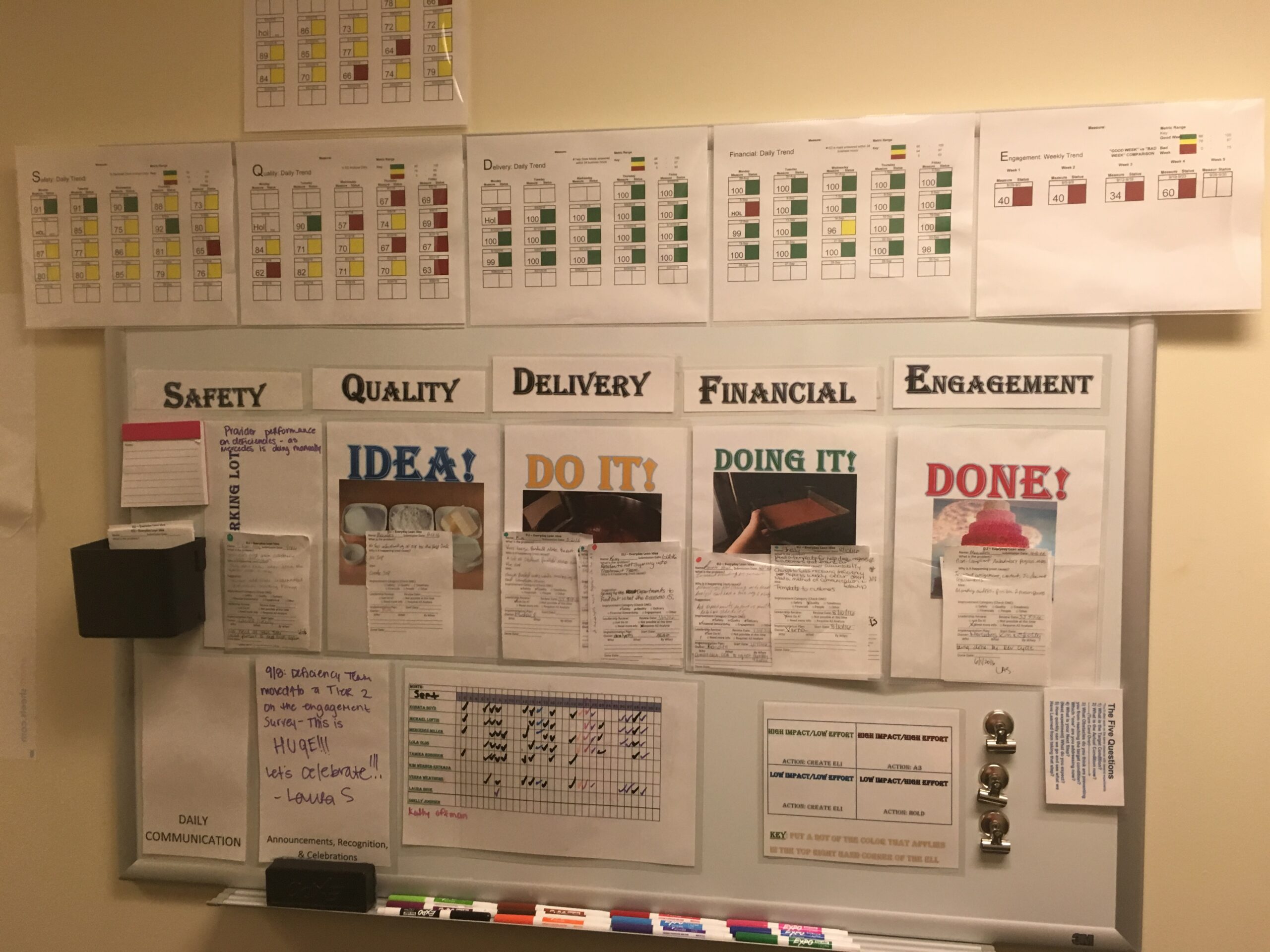

Two years later, we have Visual Value Boards in all of our units (see photos below). These are visual boards that each unit/team huddles around generally on a daily basis. Notice there is standard work to how these boards are organized, with metrics across five domains (safety, quality, timeliness, financial stewardship and engagement/people). We also have similar Executive Dashboards that demonstrate the value of the services and work our teams do across the same five domains as the Visual Value Boards.

Based on the process improvements and value we were able to create, our organization recognized one of our units as “Support Services Program of the Year (Honorable Mention)” and we also received an official Commendation from our Executive Committee on Clinical Affairs. Leadership was very satisfied.

We didn’t stop there, because since our work in HIM changes so quickly, we needed a system to keep up with documenting those changes in our workflows. It became apparent that equipping just our managers with lean skills was insufficient: we needed an entire army of lean-thinking employees! So we then began sending our line staff to “Lean in Daily Work” interval training. We really began to see the results when our line employees became empowered to identify and solve problems encountered in their daily work; they gained the skills set to document their own value stream maps and create their own experiments!

Our work continues to change, but today our staff feel like they’re part of that change instead of in the passive, victimized role of having it thrust upon them unwillingly. And of course, our leadership can see the value of what they’re doing at a glance, every time.