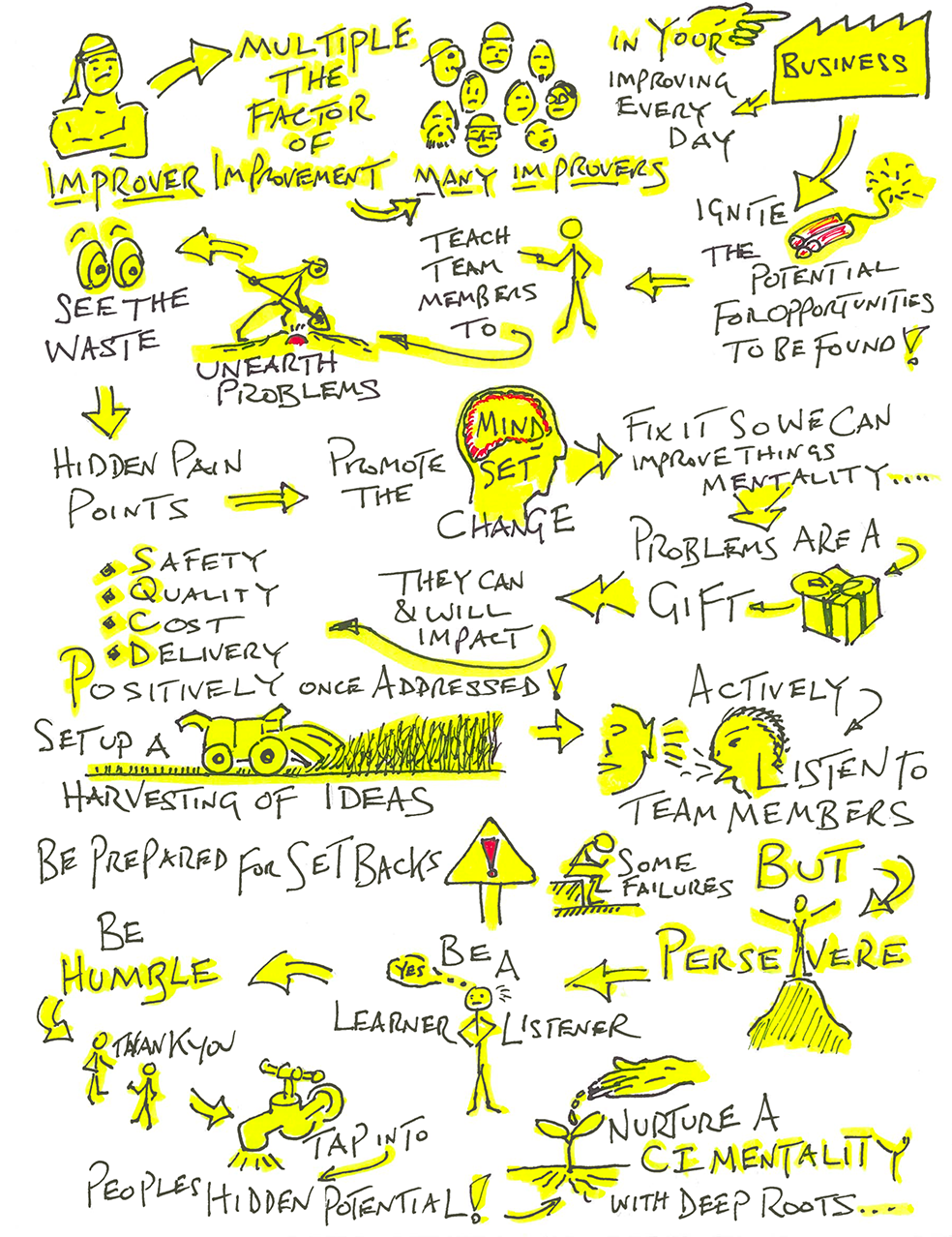

Do you have a mechanism for harvesting and igniting the potential improvement opportunities in your organization? Do your employees understand how your culture and practices leverages their kaizen spirit?

These broad goals require diligent daily practice at the ground floor of your workplace. In my last article I wrote about the tightly coupled relationship of 5S to autonomous maintenance and cleaning with inspection. This mundane work must be part of the daily routine of each team member if your goal is to create a culture of continuous improvement.

Every single person should view even the smallest problem as a gift, a trigger to make an improvement.The potential benefits of this work extend beyond simply cleaning and inspecting the work area, equipment, and machinery each person operates. Habitual maintenance affords each and every person on the shop floor a huge opportunity to discover problems, unearth abnormalities, and foster a change in the culture of business towards detecting and flagging problems on a daily basis. People shift their mindsets and want to fix problems quickly, rather than allowing them to remain hidden or worse, ignored—which is often the case within busy working environments.

Again, this is all about mindset. Every single person should view even the smallest problem as a gift, a trigger to make an improvement. Achieving these gains will inevitably boost morale while improving other key workplace conditions (such as SQDC.) That’s why team leaders should always foster “kaizen spirit” in their workers—the mindset seeking improvements every day, everywhere.

In a former organization where I worked, the use of TPM tickets became a conduit, not only for identifying and fixing obvious broken items in the workplace on machinery, but later as a channel to capture and promote improvement linked to workstations and equipment operation and inspection. This established system was able to evolve to provide a wider greater benefit for the business.

Identify and Tap Your Improvement Opportunities

What’s your mechanism for harvesting improvement opportunities? You might consider adapting something that already exists in your business for this. People inherently resist change, so if you can take something that currently exists and adjust it to an improved new state, this might be a less painful route to go in order to sell your initiative to folks. Think evolution not necessarily revolution to get buy-in to your proposals to make a process for positive improvement changes.

When you engage your team with adopting an improvement mentality, try to do so in a way that avoids any negative consequences for them from discovering problems. Indeed,Be prepared to commit the time, patience and tenacity to multiply the improvers in your organization. promote the opposite, as this is a chance to make a positive improvement by detecting issues. You want them to feel they can deeply engage with the work without any potential repercussions. You will never generate sustained gains nor change the culture without full and unrestrained buy-in, and this is a way to build trust and commitment with them.

This applies to your work as a leader: you must be prepared to see setbacks in doing this work, as you will invariably meet supervisory resistance to change such as this. Leaders will see this as an extra burden for them when team members find and flag more problems normally hidden. Expect and anticipate other people to occasionally fail to grasp or accept what you are promoting. This is a natural reaction in order to learn and ultimately succeed in making the right sustainable improvements at the points of impact at the Gemba.

Listen Actively to Your Team Members

In the past I often tried to try team member’s ideas first in an effort to win them over. I also sought to build support for my improvement proposals as the second or third option, particularly if I thought their idea may not work as they anticipated. I did this as a mechanism to build trust with the shop floor folks, hoping to gain their support from the floor to adopt my future suggestions if their solution should fail. As we developed ideas together, we all benefited from everybody’s input, and the more that people were able to nurture & influence any gains the more of a sense of ownership they felt and the more like that this work improvement would be sustained.

Over time I came to understand the need to value their input first and foremost. I’ve learned that listening to team members and not talking over them is one of the most important skills you will ever need to master. Being a good active listener is the only way to be able to grasp the potential gains and solutions team members share with you. The people who are standing at a workstation doing routine work are constantly thinking about how to do the job smarter, faster, easier, and better. They are the experts regarding the work they do. And few of us do enough to draw out their proposed improvements.

I have always tried to operate in ‘learner and listener’ mode on the shop floor. Those team members who will be there after you have gone will see you only as a visitor or temporary intruder to their workspace who may potentially interfering with what they do. It’s important not to promote that impression, so be open minded, humble, and accepting in conversation. Let them do the talking, and help them feel relaxed to engage with you.

If you can tap into the themes I have touched upon through this article in your work place, I believe you can multiply the number of improvers in your business. Just be prepared to commit the time, patience and tenacity to stick with promoting what you know is the right approach for them to adopt a CI mentality in their daily work.

Quite helpful in my lean journey.