If your organization deals with a wide variety of products that incur fluctuating demand and your customers are ever increasing the product range while demanding shorter lead times, you need to continuously experiment and adapt lean methodologies. But if you’ve read the lean management literature, most of which is based on high-volume production examples, you’ve probably decided lean principles don’t fit.

Actually they do. Principals, such as pull production, remain the same, though the methods are adjusted to fit high-mix, low-volume environments. Here’s an example.

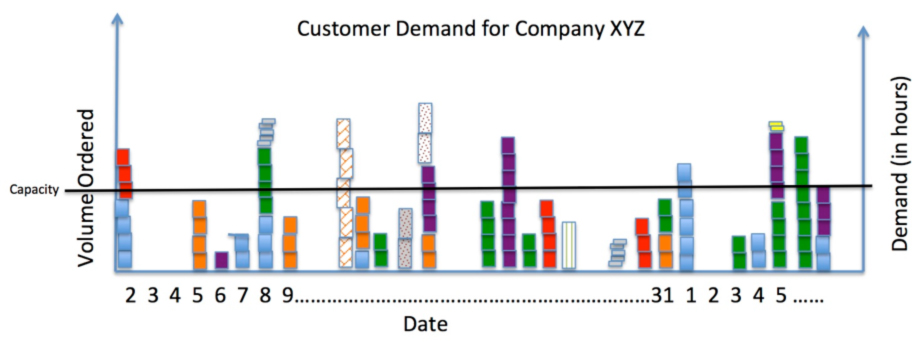

Let’s assume you have fluctuating demand across a wide range of products, (displayed by the height of the bars and various colors in Figure 1) and relatively fixed capacity. Simultaneously you must maintain high on-time delivery and control your overtime costs.

Figure 1: Varying Customer Demand

The workload — the hours of demand represented by the height of the bars — associated with customer’s due dates are not aligned with the fixed capacity. Assuming the customer due dates cannot be altered, you need a combination of solutions to maintain high on-time delivery.

Let’s further assume that the company has some repetitive product work as shown in Figure 1 by the solid colors. Production of these items recurs during this period, while other products are one-time orders, shown with the dots and stripes. This assumption is valid in most cases except for pure make-to-order job shops.

Adapting Lean for High-Mix, Low-Volume

One option involves putting in some upstream “CONWIP” (Constant Work In Process). This type of pull system in lean thinking would be maintained in the form of a kanban system, which will hold some strategic limited amounts of inventory as a buffer against fluctuating demand.

We need to put this into perspective within the context of a lean management system. This isn’t the ideal solution which would be having one-piece flow. Instead we need to consider a pull system. In lean thinking you want to flow where you can and pull where you cannot flow. The latter is the case you often will face in high-mix, low-volume environments.

Here’s how to figure out how much CONWIP inventory to hold:

- Perform an A,B,C analysis for finished goods and work-in-process (dividing products into: runners, repeaters, and strangers).

- Determine where CONWIP inventory of certain runner parts would be maintained (see below).

- Calculate kanban levels for runner parts (see below).

- Convert 50-60% of kanban levels into inventory cost so it can be weighed against the benefits incurred.

- Pilot CONWIP for a small range of products and put in a plan-do-check-act (PDCA) loop to constantly improve the system.

Lead Time vs. Inventory Cost

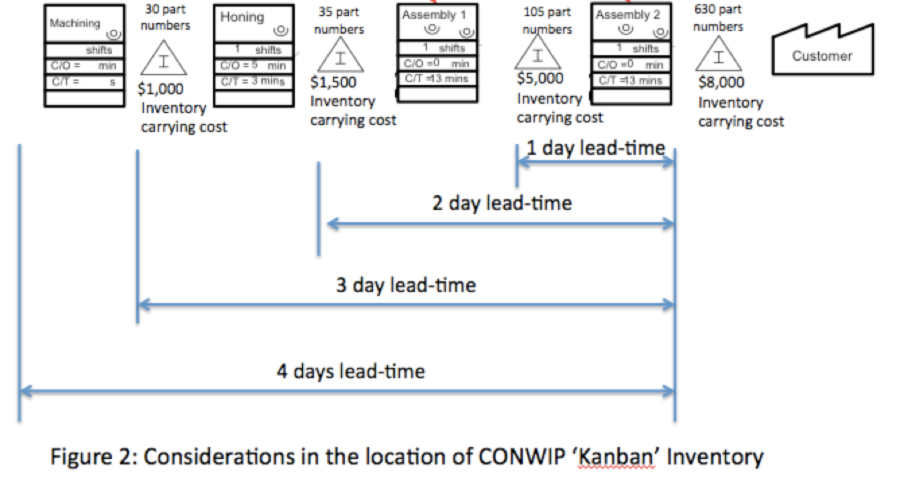

Let’s examine two key steps in more detail. First let’s examine the basic considerations in determining where to hold CONWIP inventory. The basic premise is to quantify the benefits of improved lead-time versus the cost to maintain this limited inventory. We’ll figure this based on shorter lead-time being inversely related to inventory cost as shown in Figure 2.

Logically within the flow, the closer work-in-process inventory is maintained to the customer, the shorter the lead-time to complete the remaining process steps and ship. But with each successive step more value has been added making the inventory more costly.

We must also consider that typically in high-mix operations, the further you process a product the more unique it becomes. In other words, the closer you hold inventory to the customer the more total part numbers/configurations there are which increases the potential work-in-process inventory. This is the premise for creating an analysis that has varying factors for each organization, depending on the market’s demand for shorter lead-times and the characteristics of manufacturing and storing the products. (In the example above, we would require information from the market or customer to quantify the economic impact of shortening the lead-time. For example, by achieving a one-day lead-time we could sell this product on Amazon.com and increase sales by X amount.)

Kanban Calculation

Next let’s look closer at how the kanban levels are determined for the A parts (the runners). Although there are two types of kanban (withdrawal/conveyance kanban and production instruction kanban), in this case we are planning to put in production instruction kanban.

Kanban is basically the signal to produce a predetermined quantity of parts to replace consumption. When calculating kanban levels you are actually determining the number of kanban cards or signals the will be required in the loop between the producing process and the consumption point. Therefore you are not specifically determining the inventory level, though this does represent the maximum inventory and has a direct correlation with inventory levels.

Although there are various calculation methods, almost all can be divided into four categories, each of which is individually calculated and then summed to determine the total cards/signals in the loop.

The categories are:

- Cycle Time Replenishment: consumption during the period from when the kanban signal is received until the production is complete and available for that specific card.

- Customer Variation: consideration for variation of customer demand during the replenishment period.

- Manufacturing Variation: consideration for variation in the manufacturing process during the replenishment period.

- Safety Stock/Emergency Stock: additional kanbans to cover for variations not already considered.

After using some simple equations to calculate kanban card levels (not covered in this article) for each individual category, then you sum these to determine a beginning level of kanban cards to put into the loop. It is important to remember that these calculations are based on demand and other conditions at the moment you perform the calculations, therefore you will periodically need to recalculate as factors change.

Also these calculations determine a starting level, but as with any lean system we follow the plan-do-check-act, meaning we monitor the system and adjust kanban (inventory) levels as necessary. Monitoring and adjusting these kanban levels are part of the final step, piloting the system.

Examining these two steps in some detail shows that lean methods can be adapted into high-mix operations.

In this case, we are temporarily introducing pull (instead of creating flow) while we continue to work with other lean methodologies, such as quick changeover, job instruction training, visual cross training schedules, and bottleneck analysis to increase the flexibility of capacity so in the future we can improve flow.

An interesting step in the improvement sequence is to compare the cost of holding some strategic kanban inventory to the benefits of better balancing demand with capacity. Normally lean thinking does not include cost-benefit analysis, but I include it here as we typically find a very respectable ROI while we are better serving the customer. If your boss isn’t committed to piloting a lean solution, this calculation will help.

Recommended Next Steps:

- In the workshop Improving Operations in High-Mix, Low-Volume Organizations instructor Greg Lane uses simulations, video, and examples to explain how to implement lean principles and tools within a make-to-order environment. You’ll learn a flexible implementation method that can be applied to established or early lean transformations.

- As a next step, the Managing High-Mix/Low-Volume Organizations workshop explains how your role and responsibilities as a manager will change as the company transitions to lean. Lane will show you how to increase profitability and capacity in order to grow the business without waste.

Greg Lane

Lean Enterprise Institute faculty member Greg Lane learned and implemented lean principles while at Toyota and NUMMI (New United Motor Manufacturing, Inc.), the GM-Toyota joint venture. After purchasing a job shop manufacturing company, Lane led it through a successful lean transformation. He is the author of Culturally on Planand Made-to-Order Lean: Excelling in a High-Mix, Low-Volume Environment. Greg and his associates aid companies through Low Volume Lean.