Are Japanese terms losing favor among lean thinkers?

Many lean thinkers are saying “sayonara” to Japanese terms.

In a recent community sound off question, we asked people,”Do you use Japanese terms in your lean transformation or purposely avoid them? Why?” Although the number of respondents was relatively small, the differences were big.

Of the 46 responses received through our weekly newsletter and social media…

- 48% avoided Japanese terms

- 30% used them

- 22% used both

Here are some selected quotes from each segment:Avoid Japanese Terms: “I’m sorry to say that I also try and avoid using the word lean as well.” “I want [people] to learn a new skill and way of thinking without having to learn a new language.“

Use Japanese Terms: “Japanese terms allow us to speak a common language of continuous improvement.” “We felt that since most of the books and training materials used them, it would be better in the long run to learn them and use them.”

Use both: “I fluctuate. If I’m with other lean thinkers, I’m more inclined [to use Japanese terms].”

|

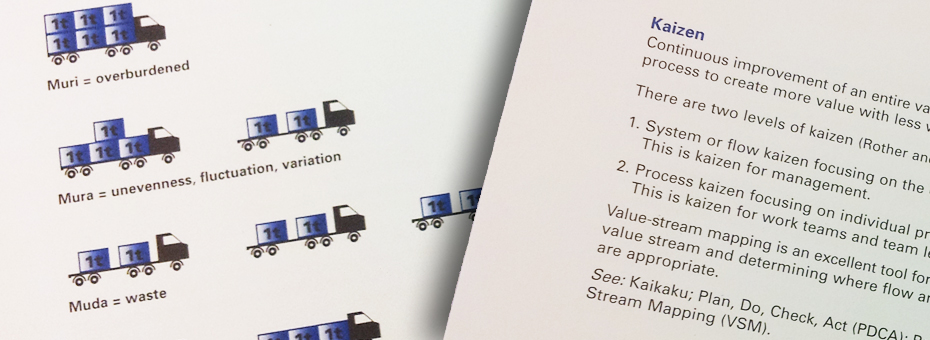

“We are avoiding the Japanese terms for the most part, based on two reasons,” wrote one respondent who summed up the main arguments for many on the “avoid” side. “We are concerned that some employees will be put off by ‘insider’ terms,” he said. “You have to be part of ‘the club’ who understands expressions like muda, gemba, and nemawashi. We [also] want Lean to feel like it is just how we do business, and anything we can do to foster it as just ‘our way,’ minus all the foreign terms, should help in gaining adoption of lean concepts.”

But several people believed the exact opposite: the use of foreign words actually helped the adoption and understanding of lean thinking.

“I want people to learn the [Japanese] terms in order to have a common language, and more importantly, to remind them that they are embarking on a new way of thinking. It takes a little more effort up front, for both me and those I’m helping … but I think the common language in the end will be worth it. The reinforcement of a new path is priceless.”

Asking Why about 5S

Some Japanese words were more problematic than others. Even people who used both Japanese and native-languages for lean management ideas, scrap-binned 5S terms for workplace organization: seiri, seiton, seiso, seiketsu, and shitsuke.

“We use a mix of both. For example, we always use kanban for a visual signal in a pull system but the 5s’s are the English version,” wrote one respondent.

Others were more blunt.

“I have seen people spending more time learning the Japanese for 5S than actually concentrating on what they mean,” one individual said. Another shared, “Trying to explain and fix to memory five seemingly abstract Japanese words for a cleaning and maintaining exercise adds no value.”

Community members from service industries seemed more inclined to avoid Japanese. A healthcare professional at an organization using Japanese terms said they stopped after getting “a lot of pushback.” Many referred to the Japanese terms as representative of “being part of the Lean cult.” One hospital associate said, “We try to avoid using Japanese terms as much as possible, as it can sometimes stand as a barrier to learning and engagement.”

A state government worker noted, “I’ve seen the positive results in our agency’s transformation over the past several years. But in this English-speaking culture most people don’t know what the Japanese words mean, much less do they want to use them. It’s as simple as that.”

Finally, a Dutch-speaking respondent said co-workers had problems using English lean terms, let alone Japanese. But they didn’t mind the sound of a Japanese term for understanding a problem through personal observation: genchi genbutusu. “They think it’s funny.”

Some experienced lean leaders maintain that a lean transformation entails a change in thinking, a change in mindset. Choosing language that reflects new ways of working and thinking can be a powerful means of affecting change.

Would more employees “buy in” to Lean if western companies stopped using words like kaizen, kanban, heijunka, and hoshin? Share your thoughts with us in the comment section below.