Be among the first to get the latest insights from LEI’s Lean Product and Process Development (LPPD) thought leaders and practitioners. This article was delivered to subscribers of The Design Brief, LEI’s newsletter devoted to improving organizations’ innovation capability.

TechnipFMC is a global leader in energy technologies and complex engineered systems in the subsea oil and gas industry. This article explores the company’s journey with the obeya management system across three parts:

- Part 1 – TechnipFMC’s successful obeya implementation in product development, adapted from Designing the Future by Jim Morgan and Jeffrey Liker published in 2018, with additional material by Morgan.

- Part 2 – Expansion of obeya management across the enterprise, led by the executive leadership team.

- Part 3 – An internal memo from Paulo Couto, Senior Vice President Industrialization and Quality, highlighting the ongoing lean transformation and its impact across the global organization.

Innovating at Depth: TechnipFMC’s Journey with Obeya in Product Development

By James Morgan, PhD and Jeff Liker, PhD

TechnipFMC is a global leader in energy technologies, complex engineered systems, and services in the subsea oil and gas industry with a market cap north of $12B. Among other things, the company designs and builds subsea production systems that control and commingle fluids on the sea floor at depths of up to 3,000 meters. That’s 9,842 feet — the deepest a human has dived was nearly 2,300 feet, a world record held by French company Compagnie Maritime d’Expertises (COMEX) — so in some ways these systems would be easier to install, operate, and service if they were in space.

The production systems consist of enormous components, including “Christmas trees,” manifolds, valves, and connectors spread out over a 30-square-kilometer area on the sea floor. They must withstand crushing pressures and incredible temperatures; resist corrosion, sand, and debris; and be operated remotely with virtually no maintenance for 25 years. And they can never, ever leak — all while controlling 50,000 barrels of oil per well per day, at 20,000 psi, and at temperatures higher than 4000F.

When TechnipFMC joined our learning group of companies they were on a mission to radically reduce the cost and complexity of their Christmas trees on a program called Subsea 2.0. Paulo Couto, SVP of Industrialization and Quality and Alan Labes, Subsea 2.0 chief engineer, were enthusiastic students of lean product and process development (LPPD) and employed many principles, practices, and tools to their advantage. One of those tools was obeya.

The team needed a level of transparency, collaboration, and fast decision-making that had not seemed possible in the past, and team members agreed to meet with other Lean Enterprise Institute (LEI) partner companies to see how they were using this powerful tool. It was an epiphany. Not only did they see the use of the obeya system in action, but they learned about how to use milestones more effectively. The team returned to Brazil fired up about employing what they learned in Michigan with LEI coaches and companies. The obeya system completely revolutionized the way that the team worked together. TechnipFMC also established the obeya system in the other engineering centers. According to Labes:

“When creating a new system from scratch, the tradeoffs involved in architectural decisions at the system, subsystem, and component level need to be tested extremely fast so the full spectrum of possibilities is covered. The obeya system enables not only that, but also enables a deep and common understanding for all the team members of the most valuable characteristics of the system and what their work must deliver to support. Obeya management system improved the process dramatically — especially due to the novel nature of the project, and the many unknowns the team had to deal with, and lessons that had to be learned during the development process.”

The team achieved the objectives of drastic reductions in size, weight, and part count, reducing complexity and shortening the lead time by 50%. And they delivered the project on time, at cost, and at a projected lead-time reduction of one-third on future orders. And best of all … the teams love working this way! And now TechnipFMC is working to spread this methodology around the global company.

But there is more. Not only did the team hit its targets on time, but it created a significant competitive advantage and a new development operating system for the company. And investors and analysts have noticed. Couto presented the breakthrough product and new methodology to an outside group of analysts, and the result was an upgrade of their stock from “hold” to “buy” and an immediate jump in their stock price. Byron Pope, managing director of Tudor, Pickering, Holt & Co., wrote just one of many glowing reports:

“Seeing is (fully) believing, and we very much like what we saw (and heard) at the Analyst Day. We were treated to what was a rather compelling TechnipFMC Analyst Day in which the company illustrated how its radical rethinking of how to best help its E&P customers improve their offshore/deepwater project economics has resulted in both improved form and functionality of the company’s subsea systems offering (FTI’s “Subsea 2.0”), a harbinger of an eventual renaissance in subsea projects being sanctioned in 2018+. The essence of Subsea 2.0 and why it is the proverbial game changer?… try 50%+ reductions in the size, weight, and number of parts associated with key subsea production systems elements (trees, manifolds, etc.). It is these sorts of innovations which heighten our confidence. Lightbulb moment of confirmation was during our rotation through the company’s Innovation & Technology Showroom (which, by the way, was our up-close … but no cameras allowed … looksee at some of the key hardware elements of Subsea 2.0) when it came to light that TechnipFMC’s leadership challenged the organization to think differently well before the most recent oilfield service industry downturn began in earnest.”*

As word spread about the incredible effectiveness of lean product and process development (LPPD) practices, engineering teams around the world began to learn about and implement them on a huge scale. One of those teams was at TechnipFMC subsidiary Schilling Robotics.

Schilling Robotics

David Furmidge is a highly experienced and very capable project engineer. He worked seven years in the aerospace industry on satellite development at Lockheed and then 10 years leading development projects at Hewlett Packard and Schilling Robotics, where he heads up their most complex and difficult ROV (remotely operated vehicle) programs. It was no surprise when Andy Houk, VP of engineering, asked him to lead the Gemini program. The vision of Gemini was to develop a robot that could travel to the work site up to 13,000 feet below sea level on the ocean floor and carry out complex tasks, including changing tools without having to return to the surface. This in and of itself would be a huge advance and save their customers millions of dollars and days of time. But they also aimed to make Gemini much simpler to operate, giving their customers increased flexibility in operator selection. In short, Gemini would be a game changer, and the most advanced and complex product ever developed by Schilling.

Even with all his experience, David knew this would be the toughest program he ever led. And as if that wasn’t challenging enough, Andy asked him to use an all-new method to develop it. According to David, “Of course, I said, ‘Yes, we will do it,’ but I was thinking, ‘Holy cow, we have got this huge project we’re doing, and now we are going to change our development practices!’ It just seemed like a lot of added work on an already difficult task.”

Despite being a skeptic, David had an open mind about learning. He and Andy were inspired by what they had read about obeya. Working with LEI coaches and exchanges with other LEI partner companies to see how project teams were using the obeya system to great benefit in their development work. Although David and Andy were impressed by what they saw at Herman Miller, they both wondered if the process would scale to something as complex and sophisticated as Gemini. David, in particular, remained quite doubtful and even kept a separate, detailed schedule in Microsoft Project on his laptop in anticipation of when “this obeya thing would all fall apart.

Schilling has an incredible experimentation culture in which people are very willing to try new things; however, those same people are also incredibly bright and opinionated. David heard initial grumblings about what some saw as just another status meeting where they had to waste time that they could have spent actually “doing their job.”

“People didn’t say much in our first few obeya meetings,” recalled David. “I think it was a combination of speaking in front of 40 or 50 people and the fact that they did not really understand or trust the process at first. So I invested some time taking small groups of people through the room and explaining the purpose. I assured them it wasn’t a status meeting; it was an issue identification and problem-solving meeting, [and] that our goal was to work together to deliver this incredible product and to support each other in the process. Within a few weeks, people started to see how powerful this system was [and] that we had a level of transparency and collaboration we had not had before. That’s when things started to change dramatically — and I even ditched my secret MS Project schedule for good.”

On one side of Schilling’s obeya room was a giant schedule. It was anchored at the top with the overall project-critical milestones as column headings. Beneath the milestones were horizontal swim lanes for each of the subsystem project teams, such as manipulator, tether management, controls, and ROV, as well as functions like software and safety. On each swim lane were placed sticky notes that identified critical tasks in support of the milestone timeline.

“At first, we only had really good fidelity for about an eight-week period, after that tasks were identified at a higher level,” said David. “And we would add detail as we progressed from left to right on the project. In the meeting, though, we really kept our focus on the upcoming week. We noted upcoming events, but we really wanted to work on what had to be done this week.”

In the meetings, individuals responsible for tasks would speak to the status of their tasks: issues they were experiencing and where they needed help. They had a movable red line that was located on the meeting date of the schedule, and everything to the left of that line should be complete. As tasks were completed, the sticky note on which the task was written was crossed off with a green pen. “By getting the group together around the schedule board it made it much easier to identify disconnects and conflicts — especially in areas where we had struggled historically, like hardware and software integration,” noted David. “As a leadership team, we never attacked or criticized a team for being behind, we just asked what help was needed. But there was a ton of peer pressure in that meeting. No one wanted to let the team down. We seldom, if ever, had someone be late a second week.” The meetings were held weekly for most of the project, but occurred daily as the project moved into the test phase and work moved faster. As the team got better, the schedule discussion only took up about 10 minutes of the meeting, and the rest of the time was spent on the product side of the room.

On the product side of the obeya room was a set of posters for each of the various project subsystems. The posters showed the latest design information, notes on the latest thinking, decisions that had to be made, and concerns or issues in a particular area. Eventually the posters were expanded to include a rich assortment of operations, safety, and supply posters. As this process matured, the team was encouraged to post questions, suggestions, or issues with sticky notes on the posters. The owners of a poster were typically given until the next week to respond to the comments. “This really helped to streamline decision-making,” said David.

Issues were not allowed to fester in the obeya, and team members supported each other as they faced challenges. Because of the obeya process, “I really felt like part of the development team,” said Hannah Waldenberger, a manufacturing engineering manager at Schilling. “We weren’t design people or operations people, we were one development team. We owned the issues and the product together.”

As time went on, Andy spotted more and more small groups huddled around some part of the obeya between meetings, working though issues or discussing plans. “That helped convince me that this was really getting traction,” said Andy.

David turned from a leading skeptic to a leading proponent. “I think the obeya management system enabled us to eliminate a lot of large issues and the associated drama that usually accompanies this type of project.” He believes that not only was it successful from a program delivery perspective, but it was instrumental in bringing the team closer together and relieving him of a great deal of stress as project leader. “I think the obeya system was the greatest contributor to our success. It helped us integrate engineering and operations into one team, and built in transparency and accountability. I could definitely see this working in [the] aerospace industry. We finished the first project phase two weeks early with no open issues — and that’s a first for us.”

Tyler Schilling, the founder, is no less enthusiastic about the obeya system. The company had experienced incredible growth over the years, but one downside of that was more and more electronic communication. He explained, “Over the last how many years, there has been a constant wind that has been blowing, a trend to do all your communicating with Microsoft tools, even with people a few feet away. I have nightmares of my most critical resources around here, inside of a PowerPoint program resizing circles, changing fonts, and just wasting their time. I thought, ‘Holy cow! I can’t have that kind of thing going on.’ And then I saw what you guys were doing with obeya. The paper charts, the Post-its® — it was a wonderful expression of spending time on substance and as little as possible on form.”

“I love attending the obeya meetings,” added Tyler. “It is a frictionless flow of information that happens in a truly efficient manner. Once a week a group of 50 people or so get a super-charged dose of what’s going on. Decisions are made and the team moves on. It’s brought back the synchronization and rich communication we had in the old days. We are advancing Gemini in a much more predictable manner than recent projects. It really reminds me of the early days at Schilling when we were just a small start-up.”

*Jeffrey Liker and James Morgan, Designing the Future: How Ford, Toyota, and Other World-Class Organizations Use Lean Product Development to Drive Innovation and Transform Their Business (New York: McGraw-Hill Education, 2018), 272.

Transforming the Enterprise: Spreading Obeya Management Starting at the Top

By James Morgan , PhD

Perhaps not surprisingly, the amazing results TechnipFMC achieved applying LPPD principles and practices in product development have led them to apply what they have learned to a massive global enterprise transformation. One of the first practices they chose to apply was obeya. And they started at the top of the organization.

With help from Couto and his team, the executive leadership team stepped up and started an executive leadership obeya. They knew it was important to lead by example, and so agreed to take the plunge. One of the lessons Couto and the team have learned over time is that obeya does not work if it is just an add-on meeting to everything else. So, he worked with the executives to determine what meetings obeya would replace. They were able to eliminate a surprising number of meetings with a single, weekly executive obeya that they hold every Monday with the company’s top leadership. Although it took some time and fortitude, they achieved the same things the program teams did. Improved collaboration, better communication, and greater transparency led to faster, more inclusive decision-making—all without PowerPoint. But there was something else, something unexpected.

Over time, the leadership became more comfortable and engaged with the process of “walking the walls” each week. As they met regularly with the company’s functional leadership in the obeya, they encountered naturally arising interdependencies and conflicts, leading to diverse opinions on resolving problems. This growing comfort with conflict allowed the leaders to push back on some ideas and challenge assumptions, resulting in better, more candid conversations. They became adept at hearing, evaluating, and either challenging or embracing different perspectives, ultimately enhancing their decision-making and management effectiveness. The decisions made were more deeply understood and supported by the leadership team.

In addition to the weekly obeya, the executive leadership team has converted their quarterly global update forums from PowerPoint to obeya style. Each quarter, they share critical updates to the top 1,000 leaders across the globe directly from their obeya with the same posted data they work with each week, further strengthening the organization’s commitment to a new way of working.

Cascading obeya management

As word spread across the organization, Couto’s team was inundated with requests for help setting up obeyas. The team decided to take a “fixed and flexible” approach to providing guidance. Since teams requesting help came from every functional organization, they knew they would need to provide the teams with flexibility in creating their own obeyas.

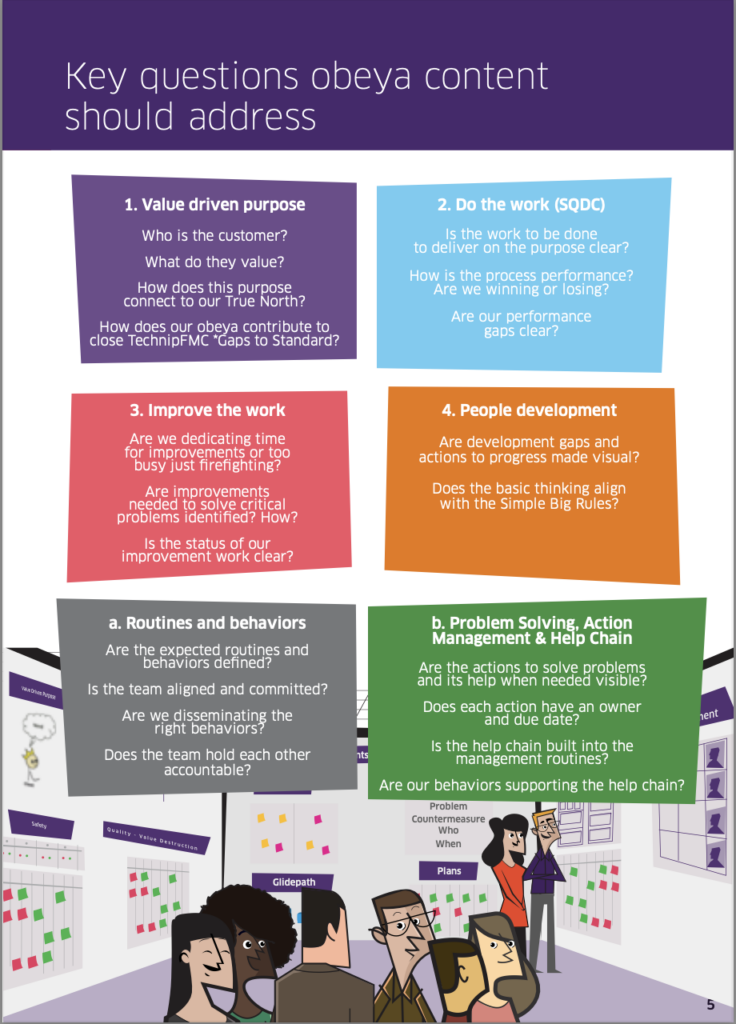

However, the team also knew it was important to share the lessons they had learned over the years. So they provided what they had learned about the critical characteristics of successful obeyas without specifying exactly what the teams had to do. These guidelines are available in a clever, small book and online on the company’s internal website. But as usual, people are strongly encouraged to work with one of the available experts as required. A small sample of the book is below:

Couto reckons they now have some 300 obeyas at various stages of maturity across the company and around the world, and he and his team are committed to helping those teams succeed. So, in addition to providing the guidance discussed above, they visit the obeyas and observe the teams in action, answering their questions and giving them feedback on how they might improve. Below is a report Couto created after visiting an obeya in a Malaysian plant.

A Case Study in Obeya Management: Lessons Shared from a Local Plant

By Paulo Couto, Senior Vice President Industrialization and Quality, TechnipFMC

Mush Mustafa leads our machining and cladding operations at our plant in Nusajaya, Malaysia. He reports to Alberto Oliveira, the manufacturing site director. Mush is an energetic Malay manager who told us he joined TechnipFMC a few years ago, coming from Toyota Motor Corporation, where he worked in Toyota City, Japan. Mush has created an obeya where he, his team, and a cross-functional support team meet daily.

Far from Nusajaya, on the other side of the planet, we are doing a huge experiment to disseminate obeyas as a new way of working. The use of obeya is expanding rapidly, violating a bit of the science of starting experimentation with a deep and narrow approach, as opposed to broad and shallow. But that’s OK. We should consider our obeya expansion a big experiment.

We’ve been visiting hundreds (yes, hundreds) of obeyas, learning with numerous teams, capturing, sharing, and reusing our knowledge. Some teams are creating obeyas with the wrong purpose in mind (e.g., to “please the boss”), but most are genuinely trying, making their best effort, to learn and improve. Out of this great big experiment, we’ve been capturing and developing knowledge to launch the “Obeya Principles and Guidance” book to define what a good obeya looks like.

We’ll publish the obeya report soon. A few weeks before the launch of this guidance, we were completely surprised to see that Mush’s obeya matches exactly what is in it. For example:

- It’s connected to the work they actually do, not to the work that others do.

- Its purpose directly connects to our company’s True North.

- Safety-Quality-Delivery-Cost: SQDC walls clearly expose problems; all plans are green and are actively being managed.

- Work improvement A3s are managed with the same criticality as their SQDC walls.

- The “people” wall shows how the organization develops its people through the work, not conventional metrics.

- Readiness levels effectively identify and gauge risks across the value stream supported by mitigation plans. Lessons learned from Subsea 2.0 will inform other products they produce.

- Posted documents explain and display the help chain sequence and hierarchy with actions, dates, and names clearly shown. Red and green stickers make problems visible.

- A cross-functional help team conducts containment and root cause analyses, which are managed with the same level of urgency as everything else.

- Where is the workplace office of the cross-functional team? Literally, at the gemba, adjacent to the obeya. That’s brilliant.

- Most obeya documents are handwritten. You can understand what is going on at a glance. When I asked what this red sticker meant, I was told it was a picture of the King of Malaysia, representing an experiment they are doing on Subsea 2.0 lead time. It means that a certain critical part cannot stop. Work on other parts must yield “right of way” to it. Love it!

- And their overall results? You can only imagine the (continuous) improvement they have made.

Incredible. How could Mush, on the other side of the planet, develop guidelines that match exactly what we are learning in our big global obeya experiment? It seems like fiction or magic, but it’s real.

Coincidence or science?

In our gemba and obeya walks together, Mush was dissatisfied with what he had done, describing some of the problems and struggles, even though, to our knowledge, he has the best obeya within TechnipFMC.

In response to one inquiry, he offered this pearl of wisdom: “It’s easier to work in an environment than to bring the environment to the work.”

Wow, I had to write it down! Mush’s words summarize the challenge and the legacy we’ll leave from our transformation — it’s easier to work in an environment that supports lean principles than to change an environment that doesn’t. Changing the environment is hard, but that’s the secret of sustainable improved performance.

A few months ago, in a conversation with Professor Jose Ferro from the Lean Institute Brasil, we shared subtle observations whenever we visited or talked to hardcore Toyota managers. Even though they have been the leading car company in the world for over two decades, ranking #1 in profitability and possessing billions of dollars in cash reserves, they always say, “Paulo-san, we have too many problems here. Our costs are too high. We have too much waste.” They print in black and white because color print is too expensive. They turn off the lights at lunchtime, and so on.

Back to our Nusajaya gemba walk.

I wish we could have spent more time with Mush and his team, but Alberto kicked us out to visit the rest of the plant. While walking out, I noticed that Mush didn’t come with us. When I looked back, I saw him walking into the cross-functional team room. I walked over to say goodbye.

“Hey, Mush, aren’t you coming with us?”

“Yes, I’m just turning off the lights here.”

“Why?”

“Because it’s lunchtime.”

And with that, our time in Mush came to an end. He and his team had not just implemented an obeya, they had embodied its principles. Their dedication, their focus on continuous improvement, and their unwavering commitment to their work were inspiring.

Let us continue to share knowledge, collaborate, and experiment. Together, we can create a future where obeya is not just a tool, but the way we manage our company.

Through relentless experimentation, TechnipFMC has demonstrated they can spread their terrific success in product development to the entire enterprise. Obeya is rapidly becoming the cornerstone of their management system, driving unprecedented levels of transparency, collaboration, and efficiency across the global organization.

What steps can you take to begin your journey to obeya management?

We extend our heartfelt thanks to TechnipFMC for their invaluable support in the creation of this series of articles. Their dedication to innovation and excellence continues to inspire and set new benchmarks in the industry.

Designing the Future

An Introduction to Lean Product and Process Development.