|

| Ernie and Tracey Richardson |

Tracey and Ernie Richardson have learned the secrets of lean through years of practice at the gemba, which helps explain why they are such popular and dynamic sensei today. Tracey and Ernie were both hired in the beginning stages of production at TMMK in 1988 and had the rare opportunity to work with Japanese trainers, learning the essence of the thinking behind the Toyota Production System. Tracey worked at Toyota for 10 years, becoming a Group Leader in the Plastics Department; Ernie spent 25 years with Toyota in a number of leadership roles, retiring in 2013. Today the two (each of whom are on the LEI faculty) are co-owners of Teaching Lean Inc., and share what they have learned around the world, leading workshops, classes, and hands-on coaching in a wide range of settings. These two have a unique gift for translating their personal experience into vivid insights that resonate with lean learners. As an upcoming week of them at LEI approaches, Tom Ehrenfeld conducted this Q&A.

Much of your lean teaching derives from lessons you learned personally while working at Toyota. How important is it that people learn what we call lean directly from experience?

Ernie and I often joke that we learned so much more because we weren’t able to speak the same language as our Japanese trainers. This barrier was in fact a useful challenge that encouraged us to use other senses to think, especially our vision; or as we call it today, “Go and See.” There were many times that we were trying to find the right words, when our trainer would nudge us to the gemba site, point at their eyes and say “look”. In other words, observe, learn, and understand. Other times we would get a hand wave, a gesture meaning a number of things: that is incorrect, look or think deeper, avoid your first instinct….please confirm and measure. Throwing away the crutch of language and certainty and relying instead on direct observation helped us in those early years to begin to differentiate facts from opinions (assumptions).

“Throwing away the crutch of language and certainty

and relying instead on direct observation helped us in those early years

to begin to differentiate facts from opinions (assumptions).”

So your teachers really couldn’t “lecture” you so much as constantly steer you back to the work itself?

Yes, this hands-on gemba approach created the “space to think.” Of course we always knew they were supporting us like a parent helping a child ride a bike without training wheels for the first time. They were “shadow steering” in the background, eager (but not too eager) to let go of the bike for the child to roll down the path. There were failures (similar to falling off the bike), sometimes on purpose, but we definitely learned from them. Our trainers would tell us – “it is okay to make a mistake, just don’t make the same one twice”. We wouldn’t be who we are today as trainers/coaches ourselves without their guidance and shared wisdom. We strive to replicate that style of learning with everyone we have the pleasure of working with.

Given your experience, what advice do you have for individuals and teams with a real interest in learning lean practice?

The key here is that we believe that Lean=People Development. Any company or organization that fails to see people as the most important asset to an organization are in danger of committing what we call the “eighth waste:” underutilization of people. Lean has to be grounded in people who understand why this “lean stuff” is so important. Without understanding purpose, and without having a way to measure lean activities, people simply won’t buy in with any depth. Lean has to be tangible to their daily work. They need to know what problem lean is solving, and they need a way of knowing when they have made real progress. We strongly believe that “the people side of lean will always trump the tool side.” Our experience strongly taught us that you don’t rely on telling, selling, and convincing someone, but rather, you help them learn by engaging, involving and listening.

In your fantastic article (“Don’t call it….anything”), you suggest that when discussing lean/CI/TPS/problem-solving/etc, “the best approach would be not to label this practice at all.” Why?

As career employees of Toyota, we are often asked to reveal the “true meaning” of various words that have become part of the lean vocabulary. The truth is, we didn’t use these particular words at Toyota. In fact, when we started in 1988, the term “lean” hadn’t become well-known, and the tools that are so familiar to us today hadn’t been formally documented. We had no filters, labels, or elaborate formal programs. Instead we were blessed to learn the foundational “thinking” based on our gemba experiences with our trainers as guides.

|

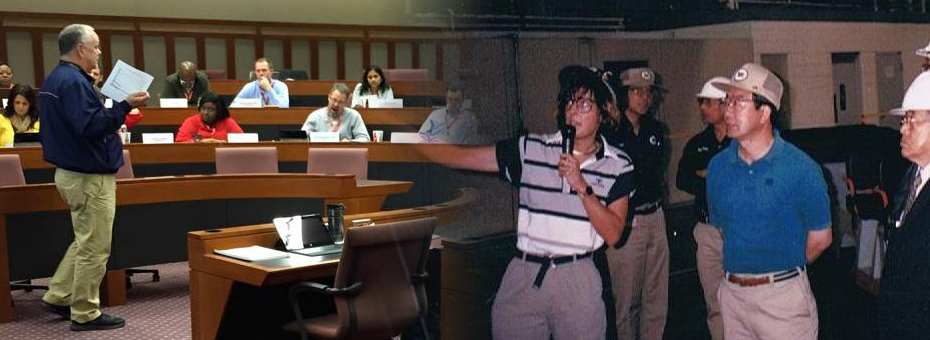

| Tracey Richardson and Shoichiro Toyoda in 1993 at TMMK. |

Our training resembled what an apprentice receives when learning a trade from a master. The emphasis was on learning by doing and teaching by example. The “classroom” for the most part was the factory floor, and there was nothing written down for us as we might see it today. We learned through the spoken word and visual demonstrations and at times, if they were close by, we grabbed a translator. Our trainers preferred to teach by asking us questions and challenging us to find our own answers even if they sensed we might be wrong.

Since this time many people have given this approach names, labels, models, houses, and much more. This practice is not a bad thing, per se: it could be tied to finding a way to spread the ideas, create alternatives, train larger numbers of people, or because it exists and seems to work for others. We, however, internally at Toyota chose to label it as our J-O-B, plain and simple. Internally, it was just part of our daily expectations. I believe if the label is misunderstood it could have a hindering effect, especially if the purpose is not explained as well. It is hard to avoid: we use the word lean – heck, it’s in our business name (Teaching Lean Inc.). One way to see it is as the appetizer to start the meal, while the meat and potatoes are in the actions.

It sounds like the Toyota culture you experienced was somewhat atmospheric in nature. What in particular developed this problem-solving mindset for you?

The Toyota culture we learned in was based on Toyota’s problems-first approach, a philosophy captured by the phrase “Toyota develops people who happen to build cars.” This meant, basically, making problems and improvement opportunities visible to workers and their team leaders, and providing people with the means to address them as close to the source as possible—in a way that fostered ownership and learning. Every day we were encouraged to think deeply about our work.

This culture has, in our view, two important pieces – the discipline to follow a path of continuous problem solving and self-improvement, and the accountability to develop, document and follow those standards. As most categorize this thinking into an add-on, it was more of a business practice and expectation for us.

Therefore, we like to speak of discipline and accountability as one, and we have labeled the concept “DNA”, which is derived from “D” ‘n “A”. In our years of training, DNA has been our Harry Potter wand – people are always wanting the magic formula that begins with how strong the company DNA is. Every year, we try to get better at helping companies grasp and attain DNA, which in our view is the key to Toyota’s phenomenal achievements.

“Toyota culture has, in our view, two important pieces—

the discipline to follow a path of continuous problem-solving

and self-improvement, and the accountability to develop, document,

and follow those standards.”

It sounds like learning and leading was very much a part of daily life—a constant process and an ongoing evolutionary state. So learning lean is not so much about reaching a set point—a full-fledged transformation from one state to another—but an ongoing state of learning and improvement, yes?

For us as leaders, there was always an expectation that we would be leading and learning simultaneously. The minute you accept the responsibility of a team, it’s up to you to be one step ahead of the people you work for. In the words of Mr. Cho – “A leader must always study harder.” Within an organization, people must continually evolve and transform at a micro and macro level. We never reach a destination with lean, but we continue to evolve as our customers and markets need us to. So I think it’s important to know lean is often fluid; we often go with the flow of the workforce knowledge base (this can be any industry) and start with a baseline and begin stretching the rubber-band within each worker at each level. The fluidity is the ability as a leader to not snap the rubber band by stretching it too far. What works well for one individual or company, may not for another; and so evolving as people should be moving the needle in the direction of true north.

Would you two consider yourself to be experts?

Actually, we tend to think of ourselves as sponges: our intentions are to always be soaking up as much information as possible from others, even if they are our students. We believe that if you stop learning and become complacent then you need to stop mentoring/coaching others. When I left my fulltime position at TMMK to become a trainer, I found some people would introduce me as an “expert.” I (and Ernie now) respectfully correct them and say that being an expert can imply that I may know everything. We always let people in on our secret that…we don’t. That truly is the secret to any trainer’s success: to always be learning and to feel confident to say, “I’m not sure I know the answer, let’s GO SEE and find out together.” You truly have to lead as if you have no power – instead “em-power.”

What plans do you have for sharing what you know?

On August 1st-5th Ernie and I will be at LEI in Cambridge doing a little “mini” conference. Five days of learning starting with the Key Concepts of Lean, then Managing to Learn A3, and lastly a real-life gemba walk nearby. So come and spent a week with us as we tell numerous stories of our times at Toyota, sharing the trials and tribulations of how we learned in a culture that had strong DNA. We will do our best to translate to you in five days what we learned over a combined 56 years. We will share cheat sheets of questions our trainers asked us on a daily basis, A3 examples, how and what to measure and much more. Classes are filling up so don’t miss out on this rare event at LEI.

Also, Ernie and I are writing a book that will be published by McGraw-Hill early next year. This book draws from our personal experiences, and delves much deeper into the DNA we discussed, as well as the true formula behind leadership standard work and how problem solving (8 steps) is the heart and soul of an organization. This is a very personal book, one that uses our experience to share lessons we learned that have broader resonance. We talk, for example, about the process of how we were hired (the competencies behind the hiring) and share numerous stories of how we were conditioned to be the thinkers we are today. It is a uniquely written book from the perspective of two workers living the Toyota Way.

Lean is clearly a huge part of your lives. You’ve shared some fun pieces in the past about applying lean to one’s personal life. Are there other areas where you have applied it?

|

| Ernie Richardson |

Yes, the “thinking” behind lean has become intrinsically part of our lives, as we’ve mentioned more of a conditioning of thoughts over the years. If you were to visit us you would see the signs of 5S in different areas, as well as labelling, organization and standardization. We have a Kanban system for our groceries and we know our max/min’s for critical items. We believe (and we may be extreme) that you have to maintain a level of standardization among daily routines in order to sustain a household properly when you travel as frequent as we do. Even our cat displays lean thinking in the form of patterns and routines (according to ours).

We view the world through a different lens than most: we see different forms of waste all around us. Honestly, it’s a blessing and a curse. We tend to notice value-stream processes that seem to be wasteful. Observing our local car wash process, for instance, we’ve come up with various ways to get more cars through with the same amount of people. This way of thinking is just part of who we are; we don’t just turn it on for a training session. It’s a lens we have been blessed (and cursed!) to receive.

On a more personal note regarding my health I used PDCA thinking to discover a rare genetic condition I have. In other words, I became my own gemba. I basically did an A3 on myself using step 2 (breaking down the problem) to help discover what my doctors weren’t able to see right away. I am, in medical terms, what they refer to as a “zebra.” By asking the right questions and finding the right ear, I was able to understand exactly what the condition was. Today I have to live my life differently, but by using PDCA on sometimes an hourly basis (reading leading indicators about myself (vitals)), I am able to adjust my processes and cope with my compromises from the condition. Learning PDCA as deeply as I did allowed me to claim my life back. Maybe one day I will write about that 7-year journey to answers.

Join Ernie and Tracey Richardson for a week of training at LEI’s office in Cambridge MA, August 1-5.