Turner Construction Company is the largest general builder in the United States, with over 10,000 direct employees and an annual construction volume of $15 billion. Turner has regional offices across the country

and internationally.

The Lean Enterprise Institute has been working with Turner since 2017 to help the firm more deeply embed lean practices and a lean mindset within the organization. As part of this Co-Learning Partnership, last year LEI helped facilitate several weekly job site coaching engagements that were only minimally disrupted because of the pandemic. On one of these, LEI lean coach and Toyota veteran Bryant Sanders worked at a job site in Dallas, where several trade partners were installing exterior panels on a building.

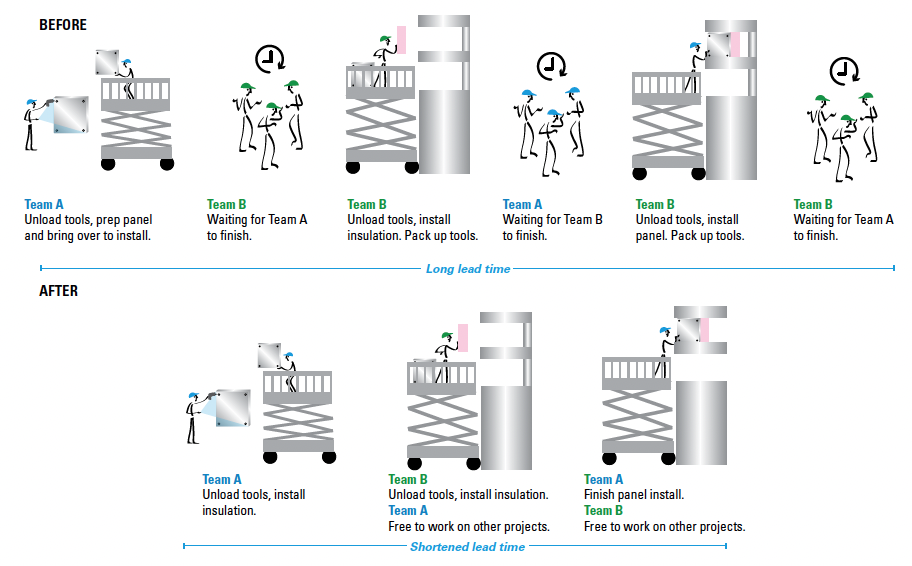

“The process did not follow what we would call continuous flow,” Sanders recalls. The contractor that fabricated the panels prepared them for installation—drilled holes, attached extrusion strips to the edges, and removed some protective film. Then the workers passed the panels to another team on a mast climber [motorized scaffold] to attach a z-shaped channel to the building and install the panels. In between, because of how the construction contracts had been awarded, another contractor was responsible for the insulation.

“That just added lead time,” says Sanders. “They would attach the channel and ride down the scaffolding; wait for the other trade partner to go up, install the insulation and come down; and then go back up and install the panels.”

Communication between the teams was inconsistent as well, adds Sanders. For example, the prep team wasn’t always preparing what the install team needed next. Generally, people had questions about why they needed to spend time improving the process when they were already meeting their targets.

“They were, in fact, meeting their daily quota the way they were doing the work,” explains Bob Grimes, Turner vice president and director of lean, adding that construction teams often don’t recognize how unplanned disruptions affect overall productivity until the deadline nears. But then, the industry’s traditional reaction to these events is to add more people and extend work hours to close the gap.

By the end of the week, the teams had improved productivity by more than 50%. ‘One day, they installed 21 panels, which far exceeded anything they had done in the past.’

— Bob Grimes

By the end of the week—with Sanders having coached them through job analysis, experimentation, process changes, and adjustments—the teams had improved productivity by more than 50%. “One day, they installed 21 panels, which far exceeded anything they had done in the past. And they weren’t breaking their backs; they were just working without the problems they’d had to deal with before,”

says Grimes.

Improving the Process of Installing Exterior Building Panels

Sanders notes that the results Turner achieved on its first project represent the quick wins construction companies experience when viewing the work with a lean mindset — and offer a glimpse of the enormous potential benefits of coordinating lean thinking and practices across the industry. For example, he explains that even if a trade partner finishes their work early, the next one has a scheduled start date. So, they can’t start any earlier because they’re finishing other jobs, which creates a gap in time that companies can’t leverage and interrupts the continuous flow.

Caution: Productivity Improvements Ahead

In the United States, the construction industry has been grappling with a shortage of skilled, capable people for years. Unlike manufacturing and IT work, construction cannot be outsourced to other countries with lower labor costs and fewer regulatory requirements.

On top of this, productivity in the construction industry has not improved much in recent decades. On the contrary, it has, by some measures, gotten worse. Getting in the way of progress is the widely held belief that there’s little to be gained by standardizing or improving work processes in construction because every project is different, with different timelines, plans, and expectations.

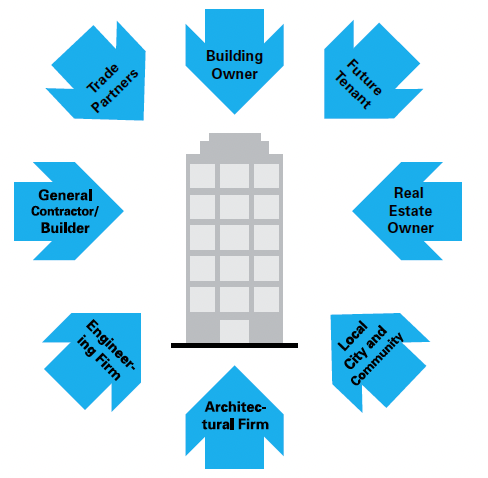

Another barrier to improving productivity is the number of different organizations that are involved in every construction project. Consider one building project:

Construction Project Stakeholders

There are the future occupant, the building owner, and whoever owns the real estate. Next, there are architectural and engineering firms. Then there is Turner, as the general contractor, which is responsible for overall project management. Finally, there are myriad trade partners (subcontractors) who construct the building and go their separate ways after their part of a project is complete.

Working with trade partners is where LEI’s partnership with Turner has had the most impact. At this level — where tangible value is created — the work has some degree of repetition and repeatability, says Sanders. But the window for improvement is tight and bound to the project schedule. So you have to get in, see the work requirements, and quickly capitalize on opportunities.

“In construction, although the work is repeatable, you only get one shot. Take this hospital in Dallas: We looked at where the painters were working on six floors. Once a floor is finished, it’s finished. We can’t go back and study it again,” he explains. “That’s very different from an auto plant where Toyota is building 1,000 cars per day. There’s a much longer runway for improvement in manufacturing.”

Opportunities Hidden Inside Every Challenge

There is an ingrained belief in construction that the work is physically demanding and tiring — and that that’s just the nature of the job. It’s even a point of pride. Everyone in the industry has lived with the strenuous physical demands for so long they don’t even see it as an issue. The work hasn’t necessarily been designed to be hard. But neither has anyone designed it to be less strenuous.

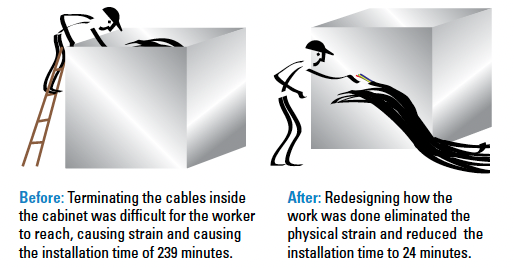

Redesigning the work eliminated significant physical strain and reduced the installation cycle time for eight cables from 239 minutes to 24 minutes.

— Bryant Sanders

In any industry or business, when poor job design makes work harder than it needs to be, it increases costs and leads to schedule overruns and rework. From a lean perspective, improving the work — removing the difficulties that cause sore hands, sore backs, and sore legs — demonstrates a respect for people, especially for trade partners and the work they do. Showing this respect is a key goal at Turner, where Actively Caring for each worker on the project sites is one of the five elements of the company’s path to success.

It comes as no surprise that making the work less physically difficult can impact productivity. In one example LEI previously shared, electricians struggled to install conductors into an electrical panel. Redesigning how the work was done eliminated the physical strain and reduced the installation time from 110 minutes to four minutes.

At the Dallas job site, the team similarly redesigned the installation of cables. In this case, redesigning the work eliminated significant physical strain and reduced the installation cycle time for eight cables from 239 minutes to 24 minutes. “We captured those guys’ hearts when we made that job so much less difficult,” Sanders recalls.

Redesigning the Work of Cable Installation

The Three Cs: Learning to See the Pain

To remove the physically demanding aspects of the work, you have to be able to identify them quickly. As noted above, the runway for making improvements on the construction site is short; the repeatable work needs to be evaluated and acted on promptly. Adapting what he learned at Toyota, Sanders shares a critical-thinking framework to help people see the work better, which he calls the “critical eye.”

To help develop this critical eye, he divides the work into three parts: content, characteristics, and categories, as shown below.

The 3C Framework

| Content | • Value add • Nonvalue-add (waste) • Incidental/auxiliary (necessary but doesn’t add value) |

| Characteristics | • Easy or difficult (physically hard) • Overburdened • Uneven |

| Categories | • Cyclical (happens at a regular cadence) • Periodic (doesn’t happen every cycle, but happens with some frequency) • Abnormal (to be eliminated) |

Consider drywall work as an example. After the drywall panels are fitted and installed, the joints are taped, the drywall compound is applied and allowed to dry, then the walls are sanded flat. Applying the joint compound is cyclical work; retrieving additional compound when the worker runs out is periodic. Efficiency gains come from keeping the work as cyclical as possible.

Here’s another example. An electrician’s job on a particular day is to terminate wires inside an electrical cabinet. At the start of the day, they will know their assignment but not which cabinets to work on or how many terminations they must finish. With a detailed daily work plan, an electrician can gather all the supplies needed to do the job without having to stop at any point to retrieve additional materials, thereby minimizing periodic work.

The final work category is abnormal work — anything that happens that shouldn’t happen. After identifying abnormal work, workers can establish standards and countermeasures to eliminate it.

Sanders offers an example he saw on a Turner job site in Denver. “They were shaking out the deck, attaching the tin bottom to the cross members before pouring concrete to make the floors,” he remembers. “They started the job but soon realized that they didn’t have the tool they needed to rivet the panels in place. So one guy had to go find it while the other two sat around being paid but unable to do any work.”

Falling under the banner of gemba-based improvement (GBI), LEI’s support is designed to help more people at Turner Construction see the work in terms of the three Cs. The emphasis is to reduce physical burdens, make the work more repetitive and cyclical, reduce the amount of periodic work, and eliminate abnormalities. In the decking example above, they built a job cart with a silhouette of every tool. Now, when the team moves to the next floor, they can easily see if they have everything they need and are less likely to leave anything behind.

The Categories of Work Motion

Human actions (motions) involved in producing products can be divided into three categories based on their value to the process.

This approach is different from a single-minded drive to eliminate waste. Identifying physically demanding work requires studying the work in greater detail — at the task and individual worker level. Sanders explains: Many novice change leaders watch people work and look for ways to improve the process. If anyone is standing around, they recognize the wasted resources and give them another assignment. Equipped with a menu of lean tools, they try to implement any of them that seems useful. After giving a team a list of action items to improve, they get frustrated when workers adopt few or none of the recommendations.

The other weakness of giving people a list of improvement to-do ideas is that they must stop doing what they’re doing to implement them. Everyone in construction — and most jobs, for that matter — is recognized, rewarded, and promoted based on output, how much they produce, and how quickly. Any suggestions or additional work that undermines immediate output they logically ignore.

That’s why, besides focusing on actual pain points, the GBI approach seeks to generate a list of improvement ideas and immediately commandeers the necessary resources to implement them. Speed is especially critical in construction, where the window of opportunity to make improvements and capture the benefits is tight.

Building Momentum in the Construction Industry

LEI and Turner coordinate conversations between trade partners To improve uptake and overcome objections on construction job sites. For example, having trade partners in San Antonio who have directly experienced the benefits of the GBI process talk to their peers in Denver or Dallas makes it easier to overcome potential misgivings and objections.

It doesn’t hurt that the financial gains mostly benefit the trade partners. After all, they’ve bid on the work and won the contract based on certain labor expectations. So, any changes that make the job easier or reduce the labor hours go straight to their bottom line.

At Turner, we’re playing the long game. By building deeper relationships with our trade partners, we will reap the benefits for the long term, allowing us to deliver greater value to our clients.

— Bob Grimes

Other significant and immediate benefits for the general contractor are increased safety, reliability, and schedule adherence. “At Turner, we’re playing the long game,” says Grimes. “By building deeper relationships with our trade partners, we will reap the benefits for the long term, allowing us to deliver greater value to our clients.”

A more daunting long-term challenge is how to work the lean approach and mindset into contracts from the beginning, to work it into the requests for proposals. To do this, people at the general contractor level must understand each project’s work requirements from a continuous flow perspective. Then, they can build potential efficiencies into the contracts (avoiding situations like the exterior panel installation described above).

“You have to take these learnings and discoveries back to the front-end of the process,” says Sanders. “Turner is embracing it — call it kaizen leadership or lean leadership—this is how the industry as a whole can begin to change.”

Management’s understanding must deepen so they can set the appropriate expectations. They have to push a vision that eliminates unnecessary hard work, for example. Engineering organizes the work the way it does for logical and historical reasons. Operations leaders must expand the factors that engineering considers during the design phase, eliminating upfront the difficult termination of conductors in the electrical panel, for example. More people in construction need to see the physical strain and future aches and pains as literal pain points that can and should be alleviated.

Another challenge, Sanders adds, is the need to move more quickly. Turner has over 10,000 employees. To expand the number of people exposed to the GBI methodology, Turner is working with its internal, self-perform group that executes some of the work on various projects like concrete or carpentry. That way, the company can directly realize some of the financial benefits, which always catches people’s attention.

Turner is dedicated to moving forward, understanding that progress is built by experimenting and capturing the learning. While the existing Turner staff is working on learning and implementing these concepts, Turner has its eyes on the future, looking forward to engaging and helping people who are just coming into the industry to learn how to see the work differently.

Turner’s Lean Structure and the LEI Co-Learning Partnership

LEI’s engagement with Turner Construction Company began in 2017 when Jim Barrett, Turner’s vice president and chief innovation officer, met with LEI Coach Mark Reich and John Shook, an LEI senior advisor, in Boston. Barrett believed that lean had been too narrowly applied in the construction industry, and there was significant untapped potential. He said he wanted Turner to be a leader in expanding its impact.

In response to that leadership pull, Reich led a pilot A3 problem-solving project among the company’s senior leadership team in its New York office. New York is the company’s largest operation in terms of annual sales. Rather than start on the job site, where LEI typically gets down to work, Reich’s intent was to leverage leader engagement and change their mindset. Changing their perspective would help them appreciate the potential and eventually cascade the new thinking and practices down to the building sites.

The pilot project did, indeed, open people’s eyes. The participants thought they spent a lot of time on job sites and understood how best to solve problems. The exercise demonstrated how they were mostly just firefighting and not really seeing the work. New York began to share their renewed understanding with the other regional leaders.

Turner has an established lean/continuous improvement program with dedicated resources. Senior Vice President Matt Papenfus is responsible for the company’s central region, with offices in Dallas, Houston, San Antonio, Austin, Denver, and Kansas City. He is also the senior leader driving the company-wide adoption and implementation of lean practices. Bob Grimes, vice president and director of lean, reports to Papenfus and coordinates the activity of regional lean leaders. They, in turn, support local lean managers in each office (40-plus across the United States and Canada), who are all well-versed in the Last Planner System™, a production control system developed by the Lean Construction Institute.

Following the pilot project with LEI, Reich met with Turner’s CEO and executive leadership team every quarter in 2019. They spent an entire day learning about lean’s untapped potential in construction in discussions, touring Herman Miller and Turner job sites. In addition to expanding the executives’ thinking, the engagement clarified the business’s need to embrace lean methodologies more deeply.

At that time, Turner and the entire construction industry faced a labor shortage. Reviewing video recordings of work on the job site during the quarterly lean exercises, company executives began to understand how much productivity could be improved.

The targeted gemba-based improvement (GBI) projects described in this article began in 2020, mostly on job sites in Texas and Colorado. They continued throughout much of the year despite the pandemic. Each team participates in three projects with increasing responsibility each cycle for identifying and implementing changes.

In addition to implementing work process improvements, Turner aims to achieve four learning objectives through the GBI projects:

- Develop a “critical eye” and other lean capabilities among trade partners and Turner’s staff.

- Deepen senior leaders’ appreciation for practical problem-solving.

- Help executives understand the business case and potential financial gains.

- Build capabilities for making the work safer, easier, and more efficient.

This strategy that Turner is pursuing with LEI’s support is a significant commitment. Time will tell how much of an impact these efforts have within Turner and the construction industry as a whole.

About Turner Construction:

Turner is a North America-based, international construction services company and is a leading builder in diverse market segments. The company has earned recognition for undertaking large, complex projects (such as Southwest Neighborhood Library in Washington D.C., shown above), fostering innovation, embracing emerging technologies, and making a difference for their clients, employees and community.

With a staff of 10,000 employees, the company completes $15 billion of construction on 1,500 projects each year. Turner offers clients the accessibility and support of a local firm with the stability and resources of a multi-national organization.

Editor’s Note: This case study was originally published December 9, 2022.

It’s very good topic. Thanks.