The founders of Haven Hot Chicken believed their home state of Connecticut was ready for an authentic southern dining experience. They saw the success of hot fried chicken restaurants in the Nashville area and wanted to introduce a similar concept to the Northeast. And drawing on their experience in the corporate world, the Haven Hot Chicken leaders knew that a good idea would only make it as far as their ability to execute. That required a steadfast focus on the production process.

Optimizing production is easy for restaurant entrepreneurs to overlook when their attention is mainly on the menu, recipes, and brand. But, with the help of Service Physics, a consultancy firm for the service industry, Haven Hot Chicken developed a just-in-time approach to order fulfillment that significantly cut customer wait times, reduced waste, and improved quality.

Haven Hot Chicken developed a just-in-time approach to order fulfillment that significantly cut customer wait times, reduced waste, and improved quality.

The founders credit kaizen events and various problem-solving tools — such as spaghetti diagrams, customer order time studies, and value-stream mapping — for helping the Haven Hot Chicken team understand bottlenecks and waste that impacted productivity and the customer experience.

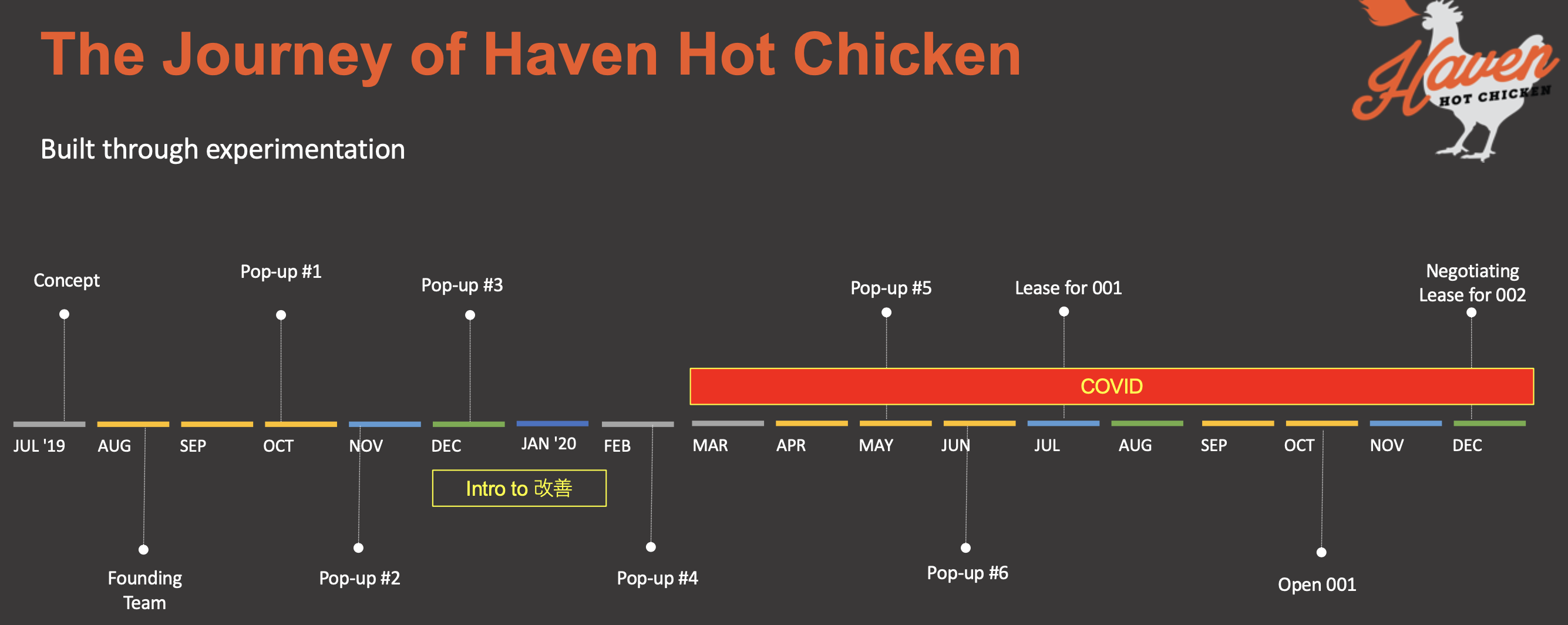

Initially, they used a series of trial runs at local restaurants and bars called pop-up events to examine and refine processes critical to the operation’s early success. It was around this time, in 2019, that the Haven Hot Chicken team learned about the lean problem-solving concept of kaizen.

“This was a transformative moment for the business,” says Etkin Tekin, cofounder of Haven Hot Chicken. “After that moment, we had a fundamental shift in our strategy and operations and focused toward strong execution of our concept.”

Visualizing Waste

The original plan to open in early 2020 stalled due to the Covid-19 pandemic. During the shutdown, Service Physics worked with Haven Hot Chicken to optimize its business practices. Before embarking on the first kaizen event, the team leaders needed to understand what customers truly value. So, the team built its continuous improvement initiatives around four key customer values, focusing on waste reduction to achieve its goals.

“If you’re not addressing waste as the business grows, the waste will grow faster than the value creation, which is why a lot of organizations — especially in (the restaurant) industry — that try to scale become a little bit top-heavy and have trouble getting beyond that five-location expansion before they topple,” says Steve Crowley, cofounder of Service Physics.

One of the ways the Haven Hot Chicken team worked to understand sources of waste was through the use of spaghetti diagrams. They first viewed a video of line cooks in action. Then, they traced the workers’ activities in the diagram and realized that there was “waste everywhere.”

If you’re not addressing waste as the business grows, the waste will grow faster than the value creation.

— Steve Crowley

The diagrams revealed that the kitchen would respond to rushes during the pop-up events by producing batches of popular items, such as French fries or the restaurant’s top seller, the chicken sandwich. That approach created delays that were unsustainable in a fast-paced restaurant. It was taking at least 40 minutes to make a chicken sandwich, which was unacceptable, says Rob LaTronica, chef and cofounder of Haven Hot Chicken.

The team used the kaizen process to establish a one-piece flow production process, pulling items from a two-bin supermarket rather than mass-producing chicken, fries, or other high-volume items in batches. So, for example, instead of keeping the fried chicken under heat lamps, they produce as close to just in time as possible, using the empty bin to signal replenishment.

Similarly, they noted that toasting multiple buns at once for several ticket orders led to considerable downtime for the next person down the line because they were waiting for the next batch. So, instead of batching items, the team decided to link each activity on the line to individual orders as they came through. Now, they sequence the bun toasting with sandwich preparation using a conveyor belt toaster.

Overall, these and other changes reduced average order times from 40 minutes to 10 minutes, LaTronica says.

The team also timed each step of making a sandwich, 12 total, using a stopwatch and the E.R.A.C.S. (Eliminate, Rearrange, Add/Subtract, Combine, Simplify, also known as E.R.C.S.) improvement technique of examining every detail of the routine. By gaining such a detailed understanding of the work, Haven Hot Chicken was able to consolidate the work to an eight-step process and cut the repeatable sandwich assembly time to 35 seconds.

The shift to a one-piece flow also had an impact on quality. In the past, batching items led to more mistakes, which were amplified because the errors impacted the entire lot. The process is more manageable for the staff because they can focus on one item at a time, LaTronica says.

Planning Ahead

The kaizen events also taught the management team the value of data-driven decision–making throughout all aspects of the operation, including strategies for inventory management.

“You want to stockpile to protect your ability to serve the guest, but if you have this data, and you rely on it, and you trust it, and you follow it, you can really dial in a lot of other aspects of the business,” LaTronica says.

The first brick-and-mortar restaurant opened in October 2020 in New Haven and has remained busy throughout the pandemic, Tekin says. Haven Hot Chicken is finalizing plans to open a second restaurant in Orange, CT, in August 2021. The restaurant’s ability to extend its lean principles to the new will location will play a key role in its ability to succeed.

“[The next challenge to address is] how do we scale and maintain the culture, maintain quality, maintain all of the things that we’re able to physically be present for and take care of,” Tekin explains. “How do we engender that trust and training in a team to be able to manage that on our behalf?”

Editor’s Note: This Lean Post is an updated version of an article published on June 3, 2021.

Nice story! The best diners have always been one-piece-flow to a great extent, though most would benefit from a bit of spaghetti diagram analysis/improvement!