Dear Gemba Coach,

Shouldn’t VSM come before 5S so we see the whole picture first?

Why not both? It really depends on what you’re trying to do. Value-stream mapping to start with assumes you want to fix the process. Five S programs to start with assume you want to fix the relationship with employees first (A note of caution: This might not be the 5S you’re used to).

It also depends on how experienced your executive team is with lean. I am fortunate inasmuch as I usually know people who have at least five years lean experience under their belts, which makes a world of difference. When they get started on a new place they kick off with:

- A 5S program on the gemba to get the teams started on kaizen;

- Visualizing where the shop stocks should be to get started on pull right away (which indeed involves drawing material and information flow analysis (MIFA) diagrams, a form of VSM);

- Key indicators and an A3 program for the management team.

The 5S program is about teaching management to engage the frontline teams in owning their workspace, and then their working practices. It’s a big jump from the traditional way businesses are run, and generally much, much easier with a leader already familiar with this.

The leader establishes a program of 5S visits and usually dedicates one coach to run a one-day workshop a week, touching every team as frequently as possible (takt time of one week usually corresponds to a plant, but of course this can change with size). The aim of this program is to:

- Teach each team the basics of 5S so they start rearranging their workplace according to what makes their work more convenient. This is really about engaging them in taking control of their own environment and, by going through the steps of sort, straighten, shine, and standardize, coming up with concrete improvements to make their work easier.

- Show interest by the leader (and line management) in what issues the teams have come up against and how they suggest to resolve them locally. The 5S visits are also an opportunity to start solving problems that the team can’t and demonstrate that management is a source of solutions as well as problems, and slowly reestablish the basis of mutual trust between management and employees (as well as see which local managers get along easily with their teams and act naturally to help them and which … don’t).

- See whether “teams” really are teams, whether they have clear areas of workplace ownership and whether natural leaders emerge through the exercise, in view of establishing “team leaders” as kaizen leaders (and not as sub-managers as many companies tend to do).

Real Purpose of 5S

The 5S program is a way to get started right away with the lean spirit of “making products by first making people.” The aim is NOT a “clean” shop floor (as many 2S or 3S programs tend to become), but really to engage the teams in their own working environment. A good 5S visit is not one where everything is all spic and span and shipshape (I’m told that in the Navy, the operating rule is: If it moves, salute it, if it doesn’t paint it), but one where teams come up with clever safety ideas, or astute ways of organizing materials and so on. One common thing leaders do to reward a good 5S is to get the area repainted so the next round of 5S becomes easier and so on.

The purpose is to deepen the relationship of the teams with their own work and to teach managers to support them in doing so.

In the similar vein of clarifying concretely where the teams are and what quality means in their jobs, the second quick action to get started is establish shop stocks – the “stores” of each micro-business, so that teams can visualize what they deliver to whom and at what rhythm (with IT or service work, this can be boards or post-its as opposed to physical stores). The wider principle is that every team owns its own production and, eventually, nothing goes through a warehouse but all components move from value-adding station to value-adding station, all the way to truck preparation.

Establishing shop stocks is often a huge hurdle for very practical reasons — not enough room, space occupied, too much inventory, etc. The purpose of shop stocks is similar to that of 5S – teams must own their production and take responsibility for their delivery. Obviously, in most environments, this is just scratching the surface of the whole ERP mess and way beyond the team’s control, but this is precisely why we start there as we try to find out whether:

- Every team is clear on what they have to do for whom and when;

- Teams can see when they’re working for a real customer need, or to stock, for instance, with batches and can identify “created demand” (demand created by the scheduling system, not the customer);

- The main blockages to producing what is needed, when it’s needed are easier to visualize.

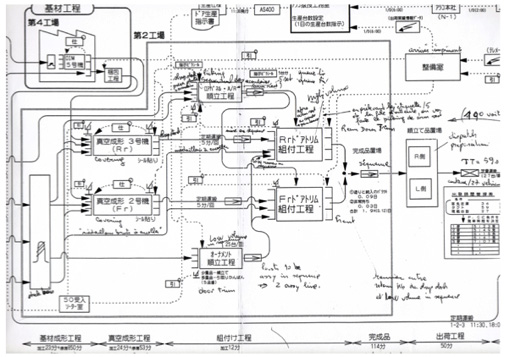

As shop stocks appear throughout the workplace it often makes sense to map them through a MIFA diagram. It’s very similar to a VSM, except that it looks at the flow of a multitude of products through the plant, not just one:

The MIFA maps out where the various shop stocks are (with all the variety involved), where products are still mixed in inventories, and what paths the flows take to have some idea of the overall complexity – as well as pickup frequency. It’s a mix between a one-product VSM and an ol’ fashioned spaghetti chart.

The purpose of establishing shop stocks and the logistics of pull is to deepen the relationships between the work employees do and their immediate customers.

“Clean the Window”

The third thing that we’ll set up right away is a management obeya room with key indicators and a program for each member of the management team to present an A3 once a week (meaning they have as many weeks members of the management team to complete it). The purpose of this formal presentation is both to deepen managers’ grasp on structured problem solving and to share their problems with each other to increase connectivity and support teamwork.

Now, as I said, I tend to know experienced lean leaders, who have hands-on experience of 5S in its kaizen form (and as a prelude to both standard work and kaizen), with setting up pull systems and using MIFAs and with the A3 problem-solving process.

It might make sense, when starting with someone new to lean, to kick off with drawing a few VSMs – this is how the lean movement got started in earnest 20 years ago. The risk, however, is to go one step further and identify problems from the VSM, which means, from the management meeting room, and not from the gemba. The deeper value of starting with 5S and shop stocks is to find what real, day-to-day problems employees encounter and start solving those before drawing any larger conclusions.

As lean leaders support ground teams in solving their problems, they see which problems are easy to solve and which are not, which teams tackle their own issues and which do not; in lean parlance, leaders are “cleaning the window.” The outcome of this hands-on process of learning by doing is that larger scale problems appear very differently from the ones initially imagined (and usually represented on the VSM if not careful). Real lean thinking starts on the gemba.

In that sense, starting with VSM can be misleading as it’s easy to project one’s a priori notions of what’s wrong with the flow on paper while creating the current state, and one’s wishful thinking on the future state. This is a trap we’ve all fallen into at some stage. Two weeks ago, I witnessed a business unit manager (experienced in lean) trying to explain to his lean officer that the VSM the latter had presented did not fully encompass the real issue, which was product variety and flexibility.

I guess that the deeper point of this discussion is to “flow to learn.” Flowing faster is not about making the process better without understanding why (which can happen when things are really bad and low-hanging fruit is easily captured). It’s about revealing the real blockages in the flow of work in concrete ways so teams themselves can kaizen them and, through their talent and passion, invent better ways to work, which will then have impacts at the executive level by changing the understanding of the business.