Not every successful business follows a lean approach to management. In fact, the vast majority of Fortune 500 companies aren’t run much differently than they would have been 50 years ago. They follow a top-down, management-by-objectives style that essentially tells managers in each layer of the business hierarchy: “Hit your numbers and you will be rewarded. How you do it is not that important.”

Managers follow this approach because it’s what they learned from their predecessors and honestly, for the most part, it has worked. The main shortcomings of command-and-control management are that it takes a long time to make sustainable changes and it discourages collaboration, which is the opposite of how companies need to perform in today’s hypercompetitive global markets. In a traditional organizational hierarchy problems accumulate and fester until they are big enough for managers to take notice. When fixes are made, the changes tend to be limited in scope and performance often slides back to the prior state after leaders move on or attention is focused on another problem.

Making a break from traditional management behavior requires a shift in mindset. But more fundamentally, it requires a change in how managers allocate their time every day. By embracing the practices of leader standard work outlined in this article, executives and managers of lean companies can begin to create a culture that:

- Solves problems quickly, creatively, and permanently

- Collaborates instinctively

- Makes continual gains in performance

- Develops the next generation of leaders

- And delivers superior financial results.

Kaizen for Management

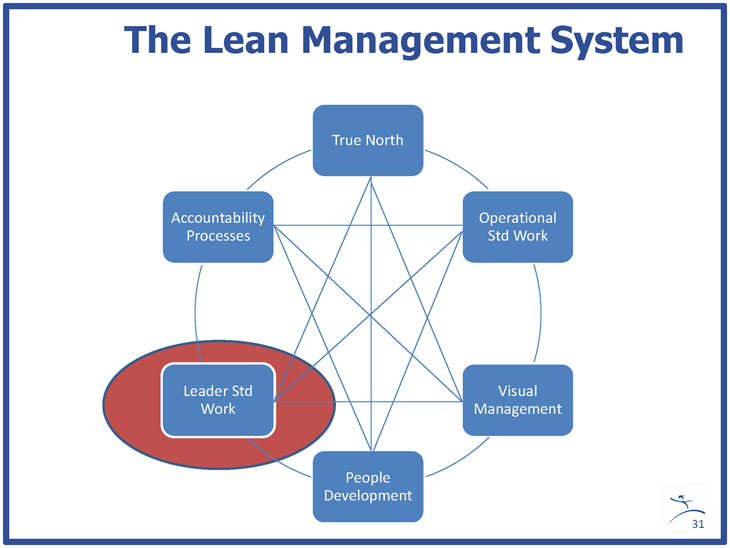

For lean companies, leader standard work changes the focus of managers and employees from being the primary problem solvers to building the problem-solving muscle of their organization. Ever evolving, it also represents the current least-waste method for planning and controlling business activities. Leader standard work is part of the infrastructure of a lean management system that includes: Pursuit of True North, standardized work, visual management, people development, and accountability systems.

- Daily team reflection

- Gemba walks

- Rapid response to abnormalities (andon)

- Mentoring

- And strategy deployment

This article briefly reviews these five elements.

Reflection

Taking the time to reflect doesn’t come naturally in the day-to-day pressure to get things done and push products and services out the door. But daily team reflection meetings keep everyone focused on the work that needs to be done, the manner in which everyone has agreed to carry it out, and where the next improvement is coming from.

Usually held at the start of the work day, during these brief meetings the supervisors, team members and managers review the basic questions of “How did we do yesterday? Where was the waste? What ideas do we have to do it better today?” Team leaders may focus on a particular problem, eliciting suggestions and solutions, and introduce classic problem-solving tools as needed. Practiced daily, these reflection meetings slowly build the team’s ability to identify root causes and implement permanent solutions following the familiar PDCA (plan, do, check, act) problem-solving process.

Gemba walks

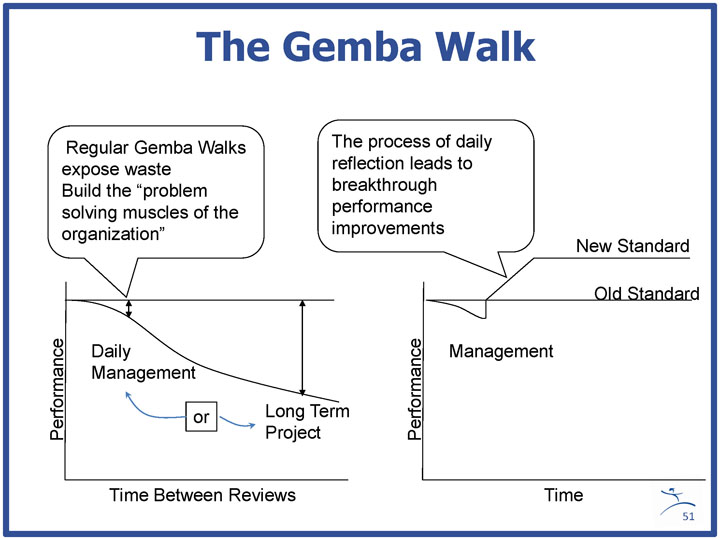

The basic idea of a gemba walk is to go to the place in any organization where people create value. When the management team goes to the gemba on a daily basis—following a regular route at a standard time, possibly using a checklist to keep track of issues—they accomplish three objectives.

First, by addressing problems where and when they occur, they help maintain baseline performance levels, which provide the foundation for future improvements (See illustration). When the work is going to plan (to standard), as shown by visual process adherence and process performance tools, gemba walks can move along fairly quickly.

Second, by modeling appropriate behavior the management team builds a culture that focuses on solving problems, and not blaming people. By not jumping to conclusions—coaching behavior that admittedly takes time and practice to learn—and asking open ended questions in a manner of humble inquiry (5 Whys), the responsibility for solving problems falls to the people and teams who are doing the work. This leverages the innate creativity of the workforce. Once people get off of ‘autopilot,’ a whole new side of them can open up, a much happier and engaged side.

Finally, because the daily business is under control, managers have more time to concentrate on the longer-term, strategic issues that will move the organization forward. Our experience has shown—this may seem a bit counterintuitive—that the repetitive aspect of gemba walks and the other elements of leader standard work, lead to more breakthrough thinking and breakthrough achievements. Rather than stifle creativity, constantly looking at a process allows creativity to emerge, resulting in new work methods and new standards that out-perform the old.

Rapid response to abnormalities

The andon cord, which originated in an automotive factory, represents more than a quality control tool . When management responds to aflashing light indicating that an abnormality has occurred, and helps resolve the issue quickly, it sends several signals to the workforce.

First, it reinforces the understanding that the gemba is where customer value is created, and that’s what matters most to the managers of the organization. Next, because problems are to be expected, and because they are opportunities for both learning and improving, it supports the message that hiding or ignoring problems undermines performance. And, last of all, it further reinforces the understanding that the people doing the work are responsible for making sure it’s done right, not supervisors or managers, or some quality inspector down the line.

Individual Mentoring

Reflection on performance and mentoring should occur at every level to further build the problem-solving muscle of an organization. A far cry from the traditional “performance review,” this element of leader standard work can require significant coaching for managers and supervisors to unlearn past behavior. It’s less about achieving specific objectives—although those remain important—and more focused on learning and growing every day.

Such reflection can revolve around general performance, when managers might ask their reports: How did we make the business better this week? How did you make yourself more valuable? What did you learn? What can I do to support you?

Or it could address specific issues: What problem do you see? How is the customer affected? Where is the waste? Why? What did you observe us doing about it? What role did you play in this?

By building each individual’s problem-solving ability, this type of reflection and coaching develops the next generation of leaders. Because such a culture can be more engaging and satisfying on a personal level for both supervisors and employees—ask anyone who has ever left such a company for a one that’s more traditionally managed—it tends to attract and retain the most talented people.

Strategy Deployment

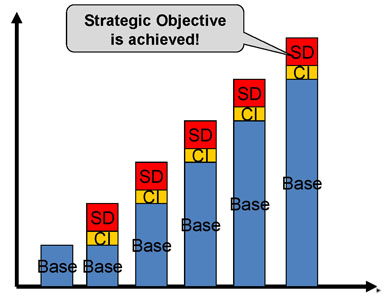

Strategy deployment is an execution planning tool. Management starts by connecting the company’s vision (or True North, which rarely changes) and three- to five-year breakthrough objectives to the annual improvement priorities. These priorities are then linked to key performance measures and flowed down to specific projects (articulated on A3s), each with clear responsibility and accountability.

Monthly progress reviews help ensure that both daily process improvement activities and efforts that support future-reaching breakthrough objectives are working synergistically to move the organization steadily toward True North. The approach gives the leadership team a structured process for managing strategy.

Create your own leader standard work

Lean proponents talk often about how the quest to eliminate waste and deliver more customer value is a “never-ending journey.” But too often, after the first couple of years, after implementing many lean practices—including operational standardized work, 5S, visual management, work cells, mistake proofing, etc.—companies do arrive at a destination. They reach a performance improvement plateau. Leader standard work is one element of a lean management system that can move an organization up off that plateau.

The use of leader standard work should not be limited to the behavior and practices outlined here, of course. These activities are simply what have emerged when leading companies have continuously applied the kaizen methodology to make their management processes more effective. That creativity never ends.

Virtual Lean Learning Experience (VLX)

A continuing education service offering the latest in lean leadership and management.