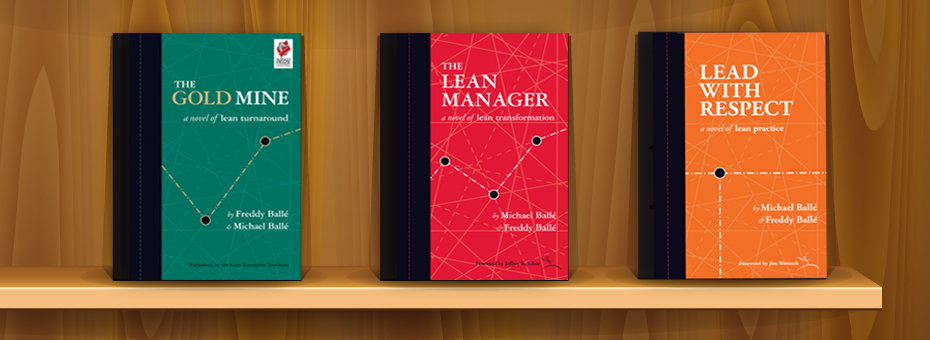

Lead With Respect, the third tome to The Gold Mine trilogy of lean leadership books I’ve co-authored with Freddy Ballé, just came out. It’s an exciting moment because this gives birth to a project Freddy and I have been working on for more than five years. Freddy first discovered Toyota back in 1975 when he was head of product planning at Renault and he heard that some obscure Japanese automaker had incredibly low costs. So he put a team together and went to go and see and came back transformed.

For most of Freddy’s executive career, he visited Japan and Toyota plants once a year, learning the language and immersing himself deeply in detailed practices of TPS. Last year we were in a Toyota warehouse together and he delved deeply into why, in a plastic container, some parts were held in a plastic bag and why others stood alone. This is TPS-land… the bored middle manager accompanying the tour didn’t have an answer so he abandoned his carefully timed schedule and started asking operators why this was the case. This resulted in a long group huddle where Freddy, our Toyota guide, and the warehouse team members discussed the ins and outs of that particular practice.

It’s easy to get lost in how detailed Toyota production practices can be, and how rigorously they are maintained through well known standards/kaizen cycles. But one thing Freddy caught early on during his visits was people involvement. He always argued: you have to walk on the two feet of continuous improvement and people involvement. If you hop along on just one you’ll fall flat on your face.

To his endless frustration, however, even as an automotive supplier CEO, his staff would embrace improvement techniques but simply not see the people involvement aspect. He had to constantly correct what they did to make them see. As soon as he left a company, the lean system would become a soulless bureaucratic machine aimed at productivity improvements by grinding people through standards, routines, workshops, etc. and lacking the bright spirit to caring and involving every employee, everywhere, everyday.

We wrote Lead With Respect to show just how central engagement and involvement is to lean success. As a sociologist, “making people to make products” is what grabbed me as I first studied how Toyota led improvement in one of Freddy’s plants. I was doing my doctoral research then, and quite naturally looked for early published stuff on TPS. The earliest information I found was a 1977 article which explicitly described TPS as a 1) just-in-time and 2) respect-for-human system. When you read Taichi Ohno’s book, The Toyota Production System: Beyond Large-Scale Production, you see that the production and psychology arguments are always deeply entwined.

After practicing lean for 20 years, first as a researcher, then as a workshop consultant, then in building large corporate programs with Freddy and now as a CEO coach, I’ve been reflecting on how I approach lean – particularly since, with Freddy’s guidance – my last ten years have been about understanding the “making products” side of “making people to make products”, which is all about lean engineering.

Recently, on the gemba with a CEO, this is what we discussed:

- Deeply understanding the value of the company’s offering (present and future) through value analysis and value engineering kaizen efforts.

- Visualize the step-by-step processes of how this value is delivered in a way that takes the ambiguity out of routine decisions and that highlights abnormal situations for team members, with clear ways to carry out kaizen activities.

- Pull every activity (here, we were discussing Kanban in the software development department) to learn how to solve problems and progressively improve the flow of work by reducing muri, mura, and muda.

- The goal of continuous improvement is… continuous improvement. No matter how much people have progressed, improve the visual management, improve test methods in order to improve the work. Create constant challenge and do constant kaizens to involve everybody in coming up with initiatives and participating to build the company.

- Create new products by deeper mastery of technical processes rather than looking for breakthrough ideas. Breakthrough ideas do arise, as engineers see knew possibilities in what can be done with integrating known technologies and new ones, but know-how is the only way to deliver robust products (notice, we’re back to value).

What strikes me, in retrospect, is how close this is to Jim Womack and Dan Jones’ original five lean principles:

- Value

- Value streams

- Flow

- Pull

- Perfection

Sure, after 20 years of hands-on research some interpretations of TPS and lean vary, and the focus on certain aspects as somewhat shifted, but the central argument remains incredibly robust. As this hit me, I read Lean Thinking again. The book does not describe large corporate programs to reduce cost. It relayed amazing stories of courageous leaders, within the Toyota environment and without, such as Art Byrne or Pat Lancaster who, much like Freddy during the same period, adopted lean as their main strategy and experimented first-hand how to make it work. How did they do this? By involving everyone in their companies and teaching lean thinking.

With Lean Thinking fresh in mind I realize that Lead With Respect is not so much about bringing the leadership element of lean into the conversation, but rather sharing the “from the inside” experience of CEOs who, like Art Byrne, Pat Lancaster, or Freddy have transformed their companies through practice by learning with a sensei, which is what the main character of the book, Jane Delaney, goes through in turning around her IT business.

Dan Jones has been a tremendous mentor for writing this book, and strong supporter of it from day one (when the first manuscript looked very different). In the end, the book has turned out to be a tribute to his and Jim’s incredible insight in capturing the essence of lean in the seminal Lean Thinking.