Some might think that detecting waste and finding inconsistency, strain and burden within a process is straightforward and easy to do. Not from my experience. Detecting and understanding the noises that can lead to machinery failure take work and practice to learn. The devil really is in the details and you have to look very closely – one missed detail can throw things way off track, or cause you to overlook critical clues or pieces of information.

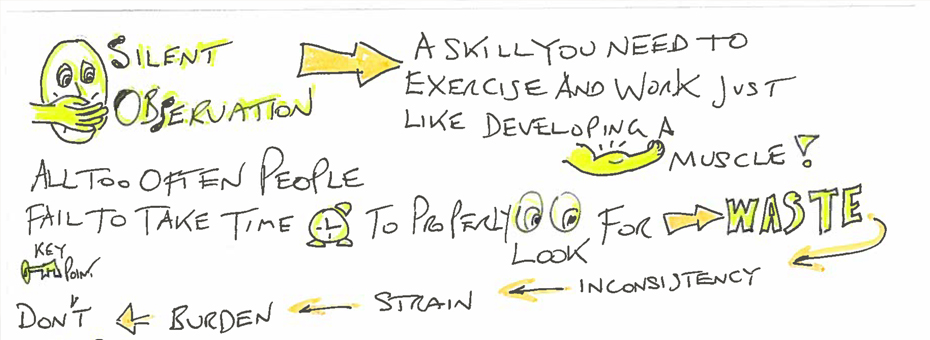

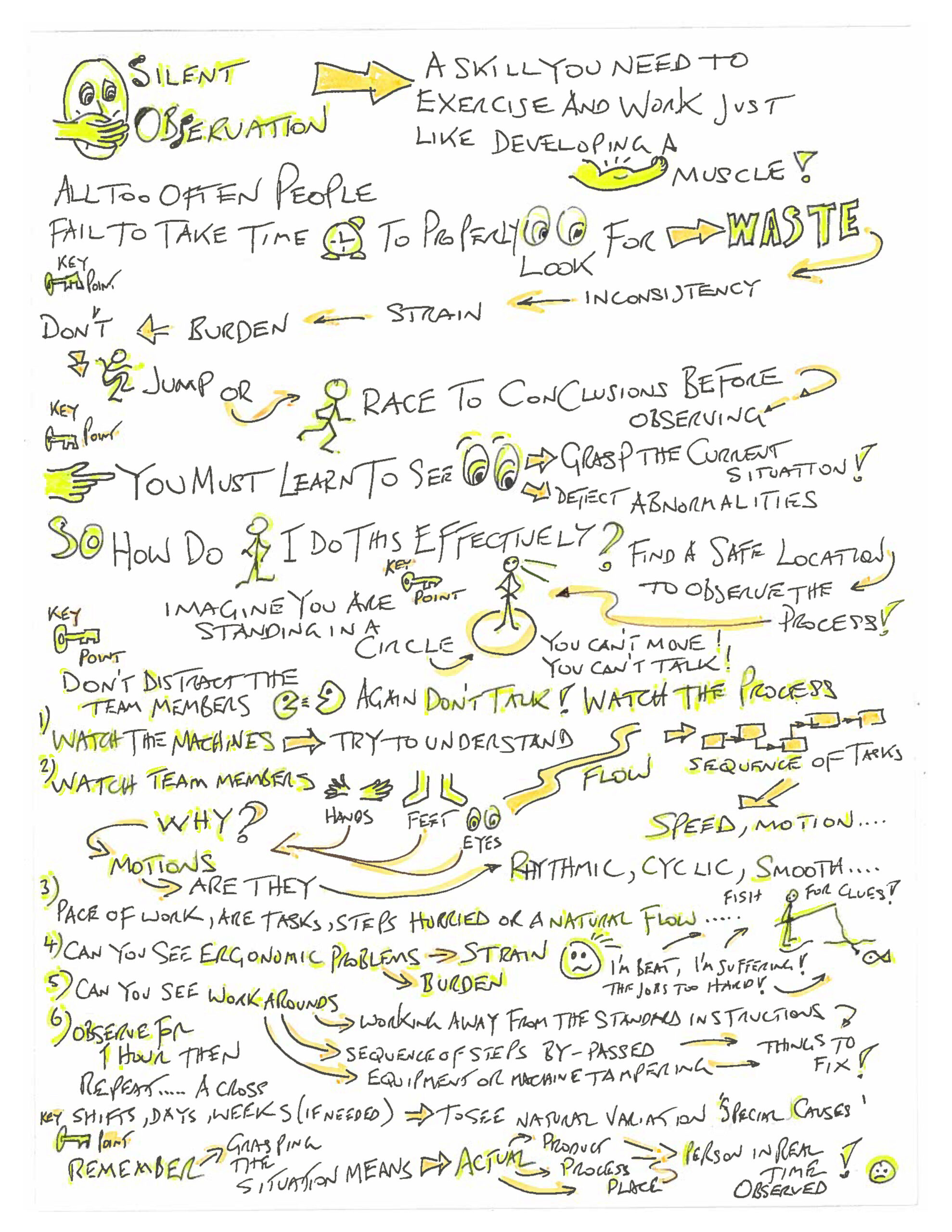

You really have to take time to closely and silently observe the process to find these “gold nuggets” of information. Again, this might sound easy, but it is not. As simple as it sounds, silent observation really is a skill you need to practice over and over again. Only with plenty of practice will you get good at detecting abnormalities, even the ones that are supple, partly hidden or infrequent.

For many years when I worked in the high-volume automotive sector, I often chased ‘seconds’ within production processes. E.g. “How can I save seconds to increase output but still ensure the process remained safe, timely, efficient, and yielded good-quality products?” My greatest OEE losses were often the events under 15 minutes’ duration that were seldom really tackled. Folks tended to treat these minutes or seconds being lost as accepted inherent conditions of the current process. In other words, a treat-the-symptom, massage-the-process mentality was often applied and that lost time was seldom fixed until the CI or lean guy arrived to analyze the process.

My approach and beliefs are to always drive the process at each step back to the original cycle/takt time first established when the process was launched. Then I look for additional gains to take waste out, confirm or create a Yamazumi chart and then look for where I could rebalance or eliminate seconds from the process or between team members.

My sketch and animated video walk you through some of my key learning points that are critical for doing silent observation properly. I hope they reinforce the message and the approach you could take.

When learning to see, go try it and practice, practice, practice…