The Backbone of Lean in the Back Shops

Achieving continuous flow, an ideal in lean production, is difficult in any business pursuing a lean transformation, but is especially tough in an environment of complex products with high variety and lower production volume such as at Sikorsky Aircraft Corp.’s Stratford, CT, plant.

“We’re learning how to do lean in a high-mix, low-volume environment,” said David Driscoll, Sikorsky’s manager of strategic sourcing and lean manufacturing. “And the proof of lean is in the back shops supplying the parts.”

Stratford does the component parts manufacturing, structural assembly, and final assembly of military helicopters, including its familiar Black Hawk and Sea Hawk models, and final assembly for its S-76 and S-92 commercial lines. Customer demand is often more erratic than in low-mix, high-volume facilities. Moreover, the back shops — parts fabrication processes — tend to have shared equipment making a wide variety of parts for multiple customers, including production assembly, and overhaul and repair operations. Further, fabrication processes must satisfy the demand for spares. The hodgepodge of parts — and resulting changeovers — coupled with high demand variation makes it difficult for Stratford to establish continuous flow. Despite the challenge, Sikorsky believed it could achieve flow in a busy machine shop making critical parts.

All in the Family

On a helicopter, parts called cuffs secure rotor blades to spindles that are part of the rotor head. The raw material arrives at Stratford’s precision machining department from an outside supplier as rough titanium forgings. An automated machining system (AMS) mills them to tolerances within several thousandths of an inch before they proceed through several subassembly steps and then are delivered to the customer. A computer and a palletized system for retrieving fixtures links the six milling machines in the AMS. Eight operators ran the machines; an MRP system scheduled them.

As part of the lean implementation, a part family matrix was created, which identified spindles and cuffs as a family of parts. Although they had different work content, the seven part numbers in the group just naturally fit the criteria for combining items into a family — they passed through similar processing steps and machines, and they had relatively steady demand and volume. Sikorsky’s lean team created a production cell for the family by dedicating four of the six milling machines in the AMS to the spindle and cuff family. (Fourteen parts families with a total of roughly 450 parts are processed in the precision machining department.)

Rapidly growing demand for a high mix of spindle and cuff parts made scheduling the cell more and more difficult using a traditional MRP-based system. MRP handled the challenge by swamping the cell with large batches of up to 70 forgings at a time. “MRP just dumped so much material in here and the cell had to work its way out,” said Driscoll. Worse, MRP often scheduled large batches of one type of forging. So, while the cell was busy working on 50 Black Hawk spindles, for example, demand for Sea Hawk spindles, cuffs, and other part numbers built up.

As a result, lead times through the cell were measured in weeks. And since demand was growing, lead times were being stretched out even further. To satisfy customers while containing costs, Sikorsky’s managers had to increase the throughput and output of the cell without making significant capital investments. They didn’t believe that continuing to rely on “hot lists” or MRP’s “push scheduling” were the answers. “We were way behind schedule,” recalled Scott Bodington, machine department manager. “We had to do something different.”

The EPE Interval

With advice from an outside consultant, Sikorsky managers applied the lean concept of “every part, every interval” (EPEI) to level the mix in demand and create flow through the cell. Driscoll described EPE as “the backbone” of lean in the machine shop.

“They had already done a lot of work to bring the equipment together into a cell,” said consultant Kevin Duggan. “What was needed next was a new way to schedule the work going through the cell and each of the processes. Calculating the EPE interval was the way to do that.”

EPEI is the frequency at which a production process or system produces different part numbers. If a machine is changed over in a sequence so that every part number assigned to it is produced every two days, then its EPEI is two days. If a value stream’s pacemaker process, such as final assembly, makes every product that it produces every day then its EPEI is one day. The interval should be as small as possible in order to produce the right mix of each part number to satisfy customer demand, and not create excess inventory that is wasteful. Instituting EPEI levels demand, protecting the process from the chaos of traditional push scheduling. This allows it to operate efficiently while supplying downstream processes at a lean just-in-time rate with exactly what they need, when they need it, and in the quantities they need.

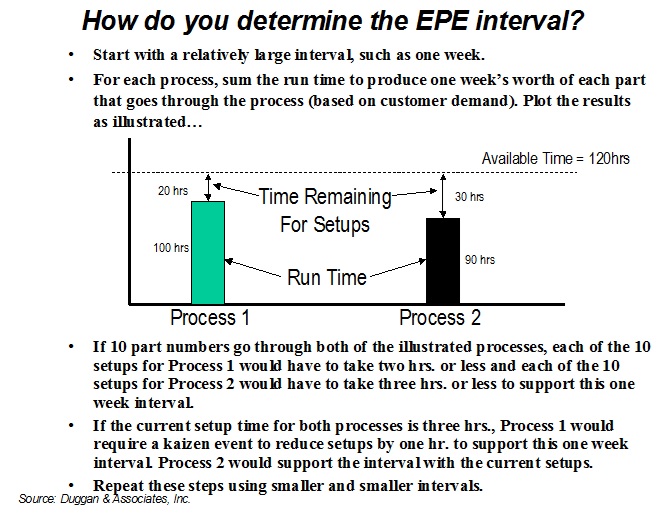

“To calculate the interval, we are looking for two things,” said Duggan. “The first is if we have enough capacity to run the parts. The second is, if we have enough capacity, how much time is left over for changeovers. That will dictate what the lot size should be.” (Allowing 10% of available time for changeovers is a typical target.) The process of determining the EPE interval is summarized in the chart below:

The Sikorsky team began the EPEI analysis by examining demand for spindles and cuffs during the previous 12 months. It had to examine two demand flows: a relatively stable demand from final assembly areas where lean improvements had created a steady tempo, but also variable demand from overhaul and repair operations. The volume and mix of part numbers was leveled to distribute the production of spindles and cuffs evenly over a period of time. “We designed a process to support a steady flow of material by leveling demand to a fixed lot size for each part number,” explained Driscoll.

The cell began with a five-day interval. Every five days it began the sequence of producing each part number with a different lot size for each part. The Sikorsky team reviewed demand quarterly — or monthly in the event of substantial changes — to determine lot sizes for each part number. The team also applied setup reduction techniques, also known as single minute exchange of die (SMED). As changeovers plunged from 30 minutes to the two and three minute range, the interval for producing every part dropped to three days, and then two days. The standardization needed to reduce changeovers and the repetition of doing them two and three times daily also improved quality, Driscoll noted.

Flow through the cell was improved further by eliminating nonvalue-added work for operators that took them away from machines. For example, instead of operators going to the tool crib for cutters, the crib started delivering cutters to operators. Flow improvements also surfaced machine maintenance needs that had to be addressed.

“The process became controlled,” said Bodington. “We had a set amount of work every two days that had to be completed.” During this EPE interval, the cell made eight Black Hawk spindles, four Black Hawk cuffs, one Sea Hawk spindle, and two spindles for the S-76 commercial helicopter. The fixed lot size for each part number created a level schedule that smoothed the demand on cell resources, established a controlled production environment, and satisfied customers. Differences in machine cycle times among the parts were absorbed by the EPE interval. “You’ll have some idle time on a machine, but you’ll get so many more pieces through the cell that you’ll be on schedule,” explained Bodington. The chart below reflects the improvements for one part number, but they are typical after the cell began using the EPE interval

Black Hawk Spindle Box Score from 1/03 to 12/03

|

Lead time |

Reduced by 73% |

|

Changeover time |

Reduced 90% to 93% |

|

Output (over a 2-day period) |

Increased 73% |

|

Actual run time compared to planned run time |

Improved by 25% |

The same improvement process is now being followed to calculate EPE intervals for additional part families in the machine shop. In the meantime, scheduling for those parts is still done by MRP.

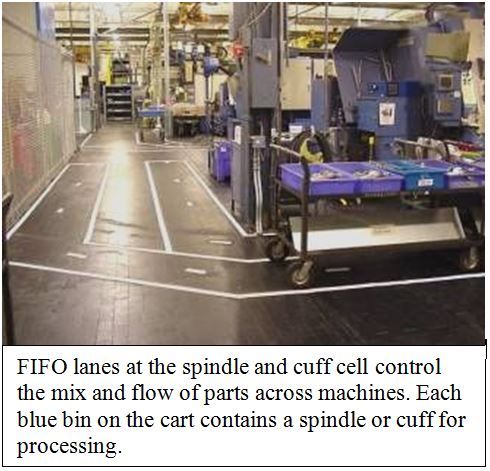

Although spindles and cuffs were a family of parts, they were not identical. They used the same equipment, but not necessarily in the same sequence; each part followed a different path through the cell. That meant Sikorsky needed a way to control the mix and flow of parts across machines. The solution was a system of multiple FIFO lanes (first in, first out) in front of each machine.

Each lane is reserved for a different part number. Material handlers wheel carts with bins containing the spindles and cuffs into the lanes. Based on the EPEI, the carts have more than one piece of the same part number. Arrows on the floor indicate the order in which operators work the lanes. When operators pull carts to process a batch of parts, they move a small “next job” card in the direction of the arrows to indicate what cart to pick from next. Diagrams or “road maps” on signposts at each machine in the cell show operators the next operation for each part number.

The multiple FIFO lanes help create flow through a shared resource. “As long as operators cycle through in order, they are able to get through a two-day bucket of each of the parts that have to go through that particular process,” Driscoll explained.

Continuous Flow Culture

Bodington introduced operators in the cell to lean at “lean 101 sessions” at the start of daily production meetings. Each session lasted a few minutes and covered a basic concept, the need for the lean concept in the precision machining department, and how the implementation process would proceed. For easy reference, essential information and concepts were printed on laminated paper, hole punched, and made into a small flip chart attached to the cell’s bulletin board. Now, a weekly “lean lesson” sheet is added to the binder after a foreman on each shift covers the lesson with operators. A recent lesson described improvements to a changeover procedure.

Mark Dorosh is the value-stream manager for spindles and cuffs. This means he oversees and improves the flow of these parts through downstream fabrication and subassembly processes. (The spindle and cuff value stream begins at the cell.) He works daily on improving the steady flow of parts and meets weekly with contacts from each department affected by the spindle and cuff value stream to identify and eliminate disruptions to flow.

Driscoll emphasizes that it is “very important” to designate value-stream managers as part of a lean conversion. By taking ownership for the transformation of an entire value stream, instead of isolated parts of it, value-stream managers can avoid the pitfall of making a change to one process that negatively affects others.

Senior managers also have taken ownership of the lean effort by championing the effort in public statements, visiting the floor to see the improvements, and holding regular but informal “town meetings” with the managers leading the transformation to discuss problems and solutions. “We’ve been able to make this work because it’s supported by our senior leadership,” said Driscoll.

For more information

Sikorsky Aircraft Corporation

A subsidiary of United Technologies Corporation, Sikorsky is a world leader in the design and manufacture of advanced helicopters for commercial, industrial, and military uses. Sikorsky helicopters are used by all five branches of the United States armed forces, along with military services and commercial operators in more than 40 nations. Based in Stratford, CT, Sikorsky has major facilities in other Connecticut locations, as well as in Florida, Alabama, and Wisconsin. Revenues are approximately $2 billion.

Workshops and Workbooks

The Lean Enterprise Institute (LEI) runs monthly regional workshops on basic and more advanced lean tools. You can read complete descriptions of workshop content with the latest dates and locations at LEI Training. LEI workbooks and training materials – all designed to de-mystify what a sensei does – show you what steps to take on Monday morning to implement lean concepts. Visit the LEI product catalog to see the resources available for supporting lean transformations.

Continuous Flow

Producing and moving one item at a time (or a small and consistent batch of items) through a series of processing steps as continuously as possible, with each step making just what is requested by the next step. Continuous flow can be achieved in a number of ways, ranging from moving assembly lines to manual cells. It is also called one-piece flow, single-piece flow, and make one, move one. (Adapted from the Lean Lexicon.)