I was fortunate to go to Japan in late 80s to study under a master sensei, Yoshiki Iwata from Toyota Gosei.

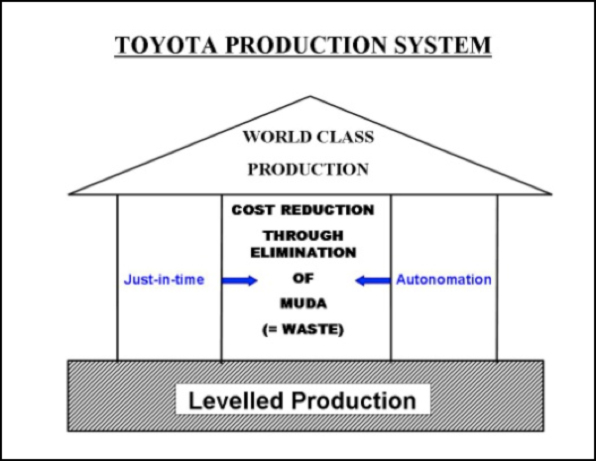

Toyota Gosei, a supplier of rubber components, was one of the first supplier companies to be taught the Toyota Production System by Toyota. Iwata drew for me this diagram of the TPS “house” which was originally drawn by Fujio Cho of Toyota.

Toyota Gosei, a supplier of rubber components, was one of the first supplier companies to be taught the Toyota Production System by Toyota. Iwata drew for me this diagram of the TPS “house” which was originally drawn by Fujio Cho of Toyota.

Levelled production forms the foundation – also known as “heijunka” – a term coined by Toyota to describe the process of levelled production. As Iwata described it, levelled production is an evolution of steps.

The initial steps are designed to create stability, which greatly supports achieving sustained continuous improvement leading to better performance. Once better performance is realized, it’s possible to increase flexibility and responsiveness to demand. This specific sequence of steps is vital. You have to create stability first to eliminate the firefighting that’s so endemic in companies. Then you can progressively match output more closely to actual demand.

This diagram shows us another important point about TPS. To many people the prime focus of Lean is waste elimination. Yet, you’ll notice eliminating waste is in the middle of the diagram. Why do many people and organizations focus on the waste elimination aspect of Lean while ignoring levelled production? Most people don’t understand how Toyota progressively implemented the steps of levelling.

The term “levelled production” implies working with and producing the same amount consistently. How can this be achieved when demand isn’t stable? Well, it is indeed a conundrum.

It is confusing to people. Aspiring lean practitioners have a much easier time understanding the role of eliminating waste in improving work flow and cost reduction. Every value stream map will show them there are plenty of sources of waste to work on. So most people see this as the prime focus of lean, not levelled production.

The aim of the initial three steps of levelling is to produce products in a fixed schedule that is rigorously followed. Same products, same volume, on the same equipment, at the same time and… in the same sequence, every cycle. Step one: in a twice a month cycle. Step two: in a weekly cycle. Step three: daily cycles.

This seems impossible and ridiculous to most people, but only because it’s so counterintuitive. People think more changeovers and shorter runs will not make them more efficient – far from it. This is one reason levelled production goes missing from so many lean transformation attempts. It just flies in the face of conventional wisdom and habits.

The key objective of these first three steps is to create stability because stability is the foundation that makes it easier to carry out continuous improvement and root cause problem solving. Then we invest in improvements to achieve faster and faster cycles. Progressively faster cycles means production gets closer and closer to actual demand. Step four and five focus on producing exactly to actual demand. First, in very small fixed quantities, then just one item at a time (this is known as one piece flow). This is the ultimate objective of levelled production.

The progressive steps of levelling are described in more detail in the 2014 Shingo Publication Award winning book I co-authored with Rick Sather, VP Customer Supply Chain Kimberly-Clark USA, Lean RFS: Putting The Pieces Together. In his foreword to the book, Professor Dan Jones says: “This book is the missing link in many Lean journeys.”

I had an exchange of emails with John Shook on the subject of levelled production or heijunka. Here’s what he said:

“Many meanings are contained in the term heijunka. Unfortunately, translation often forces the translator to focus on just one aspect. You will hear Toyota sometimes refer to heijunka as the ‘objective’ of system improvement, showing it at the culmination of a series of steps and evolution. Other times you will hear Toyota say heijunka is a ‘pre-requisite’ for attaining Lean that must be incorporated at the beginning. In fact, a ‘first stage’ heijunka is something we sometimes call ‘pattern production.’ A pattern of running each part number repetitively, perhaps using an 80/20 rule to differentiate high from low runners, is established. It is remarkable that so few industries, companies, and people have arrived at this understanding of heijunka.”

Why do you think this? Is levelled production part of your lean strategy? Do you know what the five steps of levelling are? For more information on levelled production and how to apply it read, “The Magic of Levelled Scheduling.” by Alan Mitchell.