For a very long time, the future of the Oral-B toothbrush plant in Iowa City, Iowa, seemed very secure. Since construction in 1958, the plant had earned a reputation for excellent customer service. At 311,000 square feet, it was the largest manual toothbrush plant in the world. And with product development located on site, the plant was assured of a steady stream of toothbrushes to make, which it did at the rate of nearly one million daily.

But by 2000, the plant was suddenly vulnerable. Product development had been integrated with the parent company, Braun, part of The Gillette Company. That meant the plant’s workforce now competed for new products against facilities in China and Mexico with much lower cost structures. Iowa City’s high service levels relied on high inventory levels, adding to its cost disadvantage. Its traditional MRP-driven push production system caused overproduction, creating even more inventory, which led to costly stocks of obsolete products. Add in a traditional culture with multiple job classifications that hamstrung productivity improvements, and the prospects for making toothbrushes in Iowa City were decaying quickly.

“We were facing closure,” recalled former Plant Manager Liam Cassidy, who launched a rapid turnaround shortly after arriving in 2000. The 1990s had been a period of solid growth so the prospect of closing came as “a genuine shock” to people. “They just weren’t ready for it.”

The plant, which served some foreign but mostly North American markets, was not without advantages. The workforce was well educated and had strong technical skills. Besides brush production, Iowa City did packaging and distribution, work that most plants of its type did not handle. Best of all, it was located in the middle of the company’s largest market, North America. Unlike Mexico and China, it was just days, not weeks, away from the major distribution centers for big retail customers like Wal-Mart, Target, and Costco. These factors gave it a definite service advantage over competitors — if it could reduce costs fast. Cassidy, a veteran of the auto industry where he learned lean principles, knew that a lean system based on just-in-time (JIT) production and pull would reduce lead times and inventory, augmenting the plant’s advantage in service while reducing costs.

Management met with union officials to explain what it wanted to do. “We told them the plant could compete, but we had to change and change fast,” Cassidy said. Management didn’t sugar coat the competitive threat facing the plant’s roughly 750 production and staff employees. “From day-one, I was saying the ideal number of people in the factory would be 450 to 500 and that’s how it turned out. Shedding people is never pretty. We were very, very honest and just said it’s a greater good that we’re doing by slimming down” to save the plant.

Severance packages were offered. The union agreed to a two-year wage freeze and a reduction in job classifications, first from 33 to 20, then ultimately to nine. Plant management ranks were pared. Senior positions were cut from seven to five by folding the quality assurance and information technology (IT) departments under the human resources (HR) director and combining the materials and distribution departments under a new supply chain director. These directors together with the directors of engineering, finance, and manufacturing formed a five-member operations team reporting to the plant manager.

The management team met in small groups with the remaining workers and managers to explain the plant’s problems, but also its strengths. They asked people what was right and what was wrong with the plant, then wrote 10 operating principles to address the weaknesses. They shared the principles (summarized below) with the workforce to form the basis of the transformation:

- Create an open, honest environment where good communication is treated as an essential part of our process and in which everyone has a genuine voice.

- Maintain a high awareness of the competitive environment and a constant focus on cost reduction and continuous improvement.

- Build urgency and speed of response into all processes through the empowerment of people and elimination of bureaucracy.

- Acknowledge people as our greatest asset and invest in their personal development on a continuing basis.

- Clearly communicate goals and objectives to every level and hold each person accountable.

- Develop an organization that is in constant touch with developments in technology, the markets, the wider organization and that anticipates and prepares for change rather than reacting to it.

- Design transparent financial systems so managers and supervisors have key cost measures as tools and can be held accountable for effectively managing their areas.

- Develop an effective appraisal system where all employees get an assessment of their strengths and weaknesses, with follow-up plans to address their needs.

- Take swift action to deal with personnel who obstruct or do not sufficiently contribute to change that is necessary for the continuing development of our business.

- Develop an empowered, team-based matrix organization that allows for fast decision-making and where occasional mistakes are treated as opportunities for learning.

A new business strategy focused the plant on making high-volume product families and on distribution. Manual production operations were outsourced to Mexico, eliminating an additional 150 temporary employees and allowing Iowa City to reorganize along three value streams or business units:

- CrossAction. These are premium toothbrushes made in a highly automated, proprietary process that integrated molding (forming plastic handles), brush making (inserting different sized bristles into the brush heads on handles), packaging (putting finished brushes into myriad promotional packages), and boxing the packages for shipment.

- Core Products. This product family comprised the majority of product lines made at Iowa City. Brushes are produced on large specialized machines in areas dedicated to molding, brush making, and packaging.

- Distribution. Besides making toothbrushes, Iowa City also ships directly to dentists and distribution centers for Gillette and major customers. A department serving dentists exclusively, called Professional Product Goods (PPG), has a pick- and-pack operation fulfilling dentists’ orders for Oral-B toothbrushes and 160 related Gillette products such as floss and fluoride treatments. PPG also has an imprint operation that puts a dentist’s name or logo on brushes.

Led by a production manager, a cross-functional team of people from production, engineering, quality, skilled trades, materials, and IT staffs each of the three business units. People from the central functions of engineering, quality, HR, IT, supply chain, and finance support them.

Managers and supervisors meet on the floor daily with their counterparts from the next shift during shift changes. They quickly review performance measures and problems recorded on a white performance board in each department. Production managers hold a more in-depth meeting weekly with a representative from each function to review metrics and key projects.

Machine technicians (operators) on each shift update the performance boards, recording the target number of brushes to make, the actual number made, scrap, and any problems. “We put a lot of value on people writing down the numbers,” said Patrick Flynn, manufacturing director. “It’s a powerful tool to have employees write in the results. It forces people to think about how the shift ran. And it’s important for management to be on the floor to see the results.”

Faster is Better

Oral-B managers knew that a new strategy and organization wouldn’t produce new results if work were scheduled and done the same old way. Under the traditional push system, MRP sent a production schedule to each machine in the molding, brush making, and packaging departments.

The complexity in production scheduling at Iowa City came from packaging. During a recent period, the plant made 51 finished brush types from 118 different handles types in various colors and head sizes with different sized filaments. But there were 372 different types of packaging, including foreign language promotions, buy-one-get-one-free offers, and packages combining brushes with other Gillette products. Management wanted a straightforward JIT system to send a schedule to packaging. Consumption of materials in packaging would trigger the release of signals through a supermarket pull system to replace what had been consumed. In such a system, each process has a store — a supermarket — that holds an amount of each item that it produces. Each process produces to replace what is withdrawn from its supermarket by the downstream customer process. Thus, packaging lines pull brushes as needed from the finished goods supermarket at the brush-making process. Brush-making pulls handles as needed from the supermarket at the handle-molding process. As material is withdrawn from a supermarket by the downstream process, a kanban card is sent upstream to the supplying process to trigger replacement of what was withdrawn.

Another problem with the old system was a lack of separation between production and material-handling duties. Machine technicians got their raw materials from among the roughly 140 items supplied by vendors. “Looking back, it was kind of a free-for-all,” said Carolyn Dolan, master scheduler. “We wanted to have dedicated material handlers whose main focus would be to deliver materials so we could keep our technicians running equipment.”

Working with an outside consultant, Iowa City plant management created a special just- in-time (JIT) team in April of 2001 to make the transition. Management knew it was important to involve everyone so the team included a scheduler, production manager, supervisor, warehouse manager, planner, machine technicians, and material handlers. The team first concentrated on transforming a product line, representing about half the volume of the plant, from the Core Products family. Other areas would be converted quickly. The goal was to transform most of the plant in three months.

“Faster is better,” said Cassidy. “You build up momentum and adrenalin and sweep people along.” Running old and new systems in parallel suboptimizes both, he noted.

First Steps

The JIT team included three subteams that tackled different elements of the transition: An inbound logistics subteam focused on the movement of raw materials through the warehouse and plant, plus backflushing (the practice of recording costs and deducting material from inventory when goods move into finished good rather than at every step in the production process). A scheduling subteam tackled material movement through production to finished goods. Another team provided the data the other teams needed to make decisions on key issues, such as sizing supermarkets. It also changed the IT system to support the changes with simplified user interfaces and applications for creating kitting lists, which would be important under the new pull system.

One of the first things the JIT team did was to identify the nonvalue-creating steps in the production process from raw materials to finished goods. “We got people from the plant who knew the procedures and mapped all the processes, then for each step in the process we identified it as value-added or not,” said Dolan. Involving hourly employees would encourage them to take ownership of the new system.

The JIT team spent three months designing the new system then implemented it on the shop floor during a scheduled one-week shutdown for equipment maintenance. Before people in the affected product line left for shutdown, they got at least two hours of training in the basics of the new pull system, its terminology, how their specific jobs would change, and what their new duties would be. “We tried to train from their point of view,” said Dolan.

Basically, the new system uses kanban, not MRP, to order production of materials consumed regularly, such as resins, filaments, wire, shipping boxes, brush handles, and finished brushes. Iowa City uses kanban cards to trigger replenishment in the molding and brush-making departments. It uses empty bin locations on the floor or racks to trigger replenishment of raw materials to the warehouse area of the plant and shop floor.

Items used irregularly, such as packaging materials specific to a particular job, are kitted in the warehouse section for movement to a packaging machine when needed. For example, packaging for a two-for-one campaign or a promotion destined for Korea, are kitted. “We kit what is unique to the packaged item,” Dolan explained. The new system also separated the duties of running machines from the job of kitting and moving materials.

The system begins at the packaging line with a magnetic schedule board displaying job cards for two weeks of firm orders. Every Thursday, Iowa City planners post another week of firm orders after working with planners at Gillette headquarters in Boston who aggregate information from company distribution centers. At that point, the production department owns the schedule. Production can change the sequence of orders as long as everything is done by the end of the week. “This was a big change for us because previously the scheduling group really owned the schedule and any changes had to be approved by them,” said Dolan. “That just slowed down production and we wanted to make sure people on the floor owned the schedule.” The new scheduling process improves operational efficiency and gives schedule ownership to people on the floor.

By checking the job cards on the schedule board, warehouse material handlers know at a glance what kits to assembly for each packaging job. They store completed kits in designated locations in the warehouse. Production material handlers, working with the production manager, use the schedule board to see what brushes need to be packaged and determine the order for running jobs. Working a day or two ahead of scheduled jobs, production material handlers withdraw packaging kits from the warehouse and finished brushes from a supermarket, staging them at a packaging machine.

Kit withdrawals leave empty spaces, signaling warehouse material handlers to order more materials from suppliers and make more kits. Warehouse material handlers also walk the shop floor, replenishing empty bins or floor spaces with an equivalent amount of raw materials.

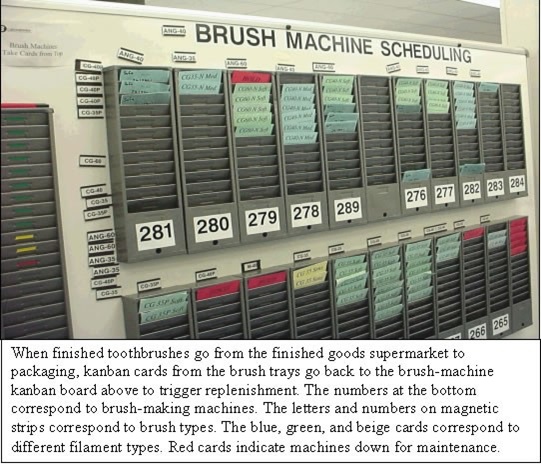

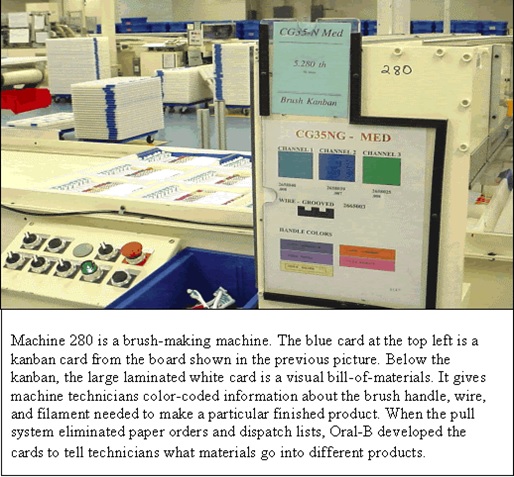

When a production material handler takes trays of finished brushes from the brush supermarket, he or she removes the kanban cards from the trays and puts the cards in the brush-machine kanban board as a sign to make more. Each card indicates the type and quantity of brushes to make.

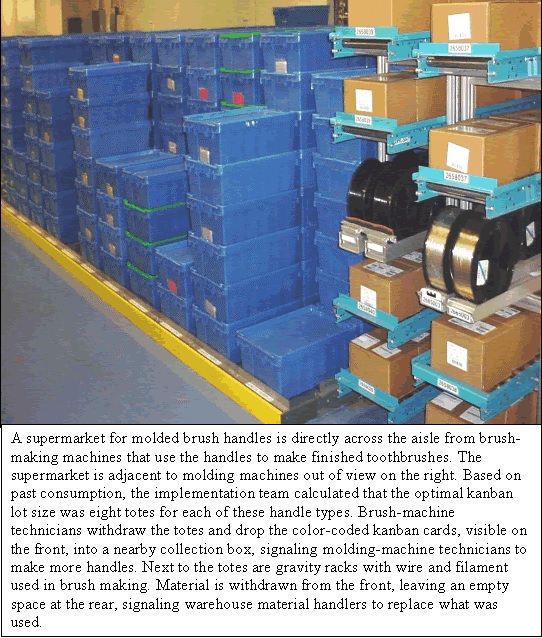

Brush-making machines consume plastic handles, which are made in molding machines right across an aisle. Handles are put in blue totes and stored in a supermarket nearby.

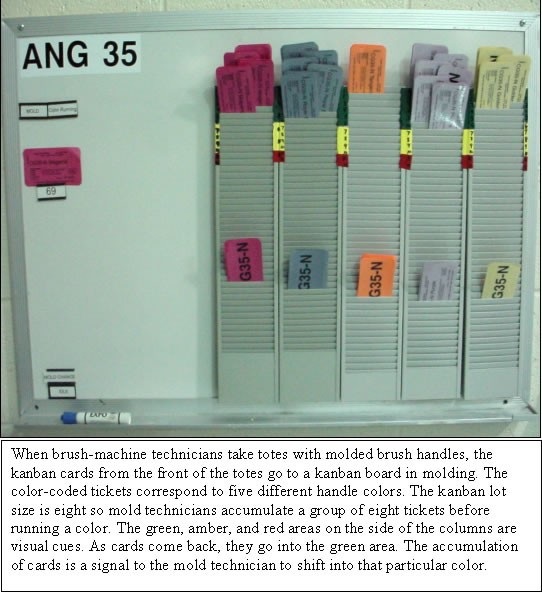

When a brush technician takes a tote to a brush-making machine, he or she removes the kanban card on the front and drops it into a nearby box. Molding technicians pick up the cards and put them on the kanban board for handles. Molding technicians, who each operate three machines, use the board to schedule production and color changeovers.

During the production process, no transactions are recorded until after packaging when a production material handler enters the part number and number of cases made into one of just a few computer terminals left on the shop floor. When finished goods are booked, a transaction occurs as a backflush to the lowest raw material level.

People adapted quickly to the system. “The new system was so much simpler than the old system, that people were asking, “When are we going to go on JIT,” Dolan said. “It made their jobs a lot easier.” For example, machine technicians now concentrated on operating equipment and performing changeovers. They no longer had to requisition and retrieve materials or key in production data on every product run.

After three months, the team had converted an estimated 70% of the shop floor to the new system, achieving its goal. Inventories were down dramatically; most products were made on a weekly basis. By 2002 Iowa City was competing strongly in costs and other areas with Gillette facilities globally. By 2004 it was one of the overall top performers in the company.

Pennies in Costs

Having a workforce that is willing to change is one of two keys for companies that want to compete in North America, said Cassidy, who now oversees two Braun Oral-B plants in Ireland and one in India. The other is that management must understand the true costs. “They have to realize what is draining the cost base. Have they really looked at all the products. Does it make sense to manufacture everything in-house; sometimes it makes sense to rationalize.

Said Cassidy, “Outsourcing should be a strategic part of any business these days so it’s absolutely necessary to do that from time to time and in certain situations. Having said that, assuming that North America is the largest market — and it is for almost everything that is made on the face of the earth — then I think it’s an act of folly if you have a manufacturing base here to move it away.”

He noted that China and Mexico are weeks away. “Responsiveness and being close to market is just so immensely important.” That gives Iowa City “a huge supply chain advantage.” The total cost difference between it and plants in China and Mexico now is “pennies and not at all significant. Iowa City’s efforts virtually had erased its cost disadvantage.

Iowa City Plant Box Score 2001-2004

| Direct costs | ↓18% |

| Headcount | ↓38% |

| Productivity | ↑55% |

| EPEx (every product every interval) | 1 week for most items |

| Schedule Adherence (2003) | 99.3% |

| Overall Equipment Effectiveness (2004) | 93% |

Kaizen Evolution

In April 2002, managers and employees were ready to build on the initial success with a continuous improvement effort. The outside consultant returned to train seven managers as kaizen event facilitators and run the first few kaizen events. The plant facilitators, drawn from a variety of functions, kept their regular jobs in addition to shouldering the planning, facilitation, and follow-up of kaizen events. All employees received additional training that included a simulation using lean principles.

Oral-B’s five-day kaizen events followed the standard approach of mixing some classroom work with a lot of shop-floor activity to identify and implement significant improvements immediately.

Two to six events are run each quarter. Kaizen teams members are drawn primarily from target work areas, but employees from other areas are recruited, too. Management reviews the results at the end of the event and checks for completion of follow-up activities in 30 days.

Many early kaizen events focused on improving machines to make them more reliable and in less need of adjustments. Reducing machine cycle times also was an initial kaizen goal.

“The scope of our events has changed with time,” said Brian Donovan, a business systems manager and the plant kaizen coordinator. “Our projects have tended to be process kaizens focusing on individual problem areas. We are currently having discussions on how we can use more value-stream analysis to open up our projects to the bigger overall picture and begin to work on business bottlenecks and waste. In addition, more traditional support areas, such as accounting, IT, engineering, etc. are good targets for future events as well.”

The ultimate goal is to create an environment that allows day-to-day problem solving to just happen without need for formal direction.

Brian Donovan, Business Systems Coordinator and Plan Kaizen Coordinator

The ultimate goal is to create an environment that “allows day-to-day problem solving to just happen without need for formal direction,” Donovan said. “We feel we have just begun to tap the possibilities, especially around empowerment.”

Late in 2003, management was ready to tap more possibilities of lean. It believed the system could be extended to PPG, the distribution operation serving dentists. The goal was to improve service while lowering finished goods inventory to save money, space, and time spent setting inventory levels.

Extending Kanban

Iowa City ships about 1,500 orders for toothbrushes and other oral-care items to dentists daily. Finished goods levels for the various toothbrushes were set at headquarters in a two to three-week cycle involving sales, marketing, and demand planners using forecasts and inventory data.

“We felt pretty successful using kanbans to control work-in-process,” said Dolan. “So we said, Hey we’ve got finished goods for the profession right in the distribution center.

Why have planning in Boston plan the inventory that we’re carrying here?” Using a pull system to automatically trigger toothbrush inventory replenishment would provide immediate information about stock needs directly to Iowa City. The plant, with its JIT flexibility, could respond immediately, improving service while lowering inventory levels and the administrative effort spent setting them.

A pilot project team examined product shipment history for the previous 32 weeks. The team calculated the standard deviation for average weekly shipment volume on each product. Products with low-volume and high variability registered a high standard deviation. They were unsuited for kanban control and were classified as make-to-order.

Products with low-volume and low variability were designated “suitable” for kanban. Products with high volume and low variability were designated “ideal” for kanban. A product line from the latter group was chosen for the pilot. Using its volume variability analysis, the team calculated new inventory levels for the product at roughly half the previous levels, including stock as a buffer against spikes in demand. “We put aside space in the warehouse and assigned a card to each pallet of product,” Dolan explained. “The trigger here was customer shipment.”

When a pallet of toothbrushes was taken to the pick-and-pack line filling orders for dentists, the kanban card was sent to the packaging schedule board in the plant. When a certain number of cards were accumulated, the product was scheduled to run. In five weeks, the new process reduced inventory costs by 39% with no customer service problems or increase in machine changeovers.

After the successful pilot, the kanban system was extended to other appropriate product lines. The change is allowing planners in Boston and Iowa City to focus more on smoothing the introduction of new products while phasing out old products. “We’ve taken finished goods planning out of the mix,” said Dolan.

Next Steps

One of the next steps for Iowa City is to work even closer with suppliers, according to Anita Falkofske Eaton, the new plant manager. Key suppliers now have blanket purchase orders for the amount of raw material that Iowa City expects to purchase. They are expected to keep a minimum amount of inventory, generally a month’s worth, on hand. Once or twice monthly, vendors and Iowa City staff review stock levels at the plant and the vendor’s facility and discuss upcoming production plans.

“We’ve really only started to realize benefits from suppliers,” Eaton said. Most suppliers are traditional manufacturers that will benefit as Iowa City managers start to help them streamline operations to cut costs, a development that helps both sides. The plant will also continue to refine its lean system, improve people’s problem-solving skills, and foster employee involvement and training.

“We’ve plenty of opportunity to make further improvements,” Eaton said. “We plan to continue our program to increase the education and skills of our employees and to search for new, innovative ideas. Continuous improvement will help us remain competitive, as we can’t afford to backslide.”

For more information

Founded in 1950, Oral-B is a leading provider of oral care products to consumers, dental professionals, and retailers worldwide The Oral-B brands have helped The Gillette Company become the worldwide leader in both the manual and power toothbrush markets. Oral-B is the leader in the $4.5-billion toothbrush category, marketing toothbrushes as well as products such as dental floss. The Oral-B brand includes power toothbrushes for adults and children, as well as interdental products such as irrigators. Its toothbrushes are used by more dentists and consumers than any other brand in the U.S. and in many international markets.