People often ask me: how does one get CEOs to adopt lean? I honestly don’t know. The CEOs I work with are curious about lean in the first place. I generally explain that what we mostly do is discuss the business current state, then draw the Toyota Production System(TPS) “house,” then go to the gemba to see what we get right and what we don’t, and observe new problems appear; and then discuss with the people how they see things, what they think about the problems and what they could do about it. I’m mostly met with puzzled disbelief.

And yet, it works.

Which begs the question: what is the theory of lean? How does it actually work? And why always go back to the TPS rather than a simpler version of lean thinking?

The starting point of lean thinking sets the bar rather high: the CEO has to accept that although they know a lot (and I mean a lot) of things about their business, the correct answers to key, competitive problems remain unknown. All we have is countermeasures for problems as we understand them. But, if we seek to better formulate problems and study countermeasures and their results with the people doing the job themselves, we must understand problems more deeply, and discover hitherto unthought of ways of doing things and improving work, with the people themselves.

So, although we don’t know all the answers, and all we have are temporary and local countermeasures, we have a way to look for better responses.

The Toyota Production System, really, is a concrete theory about how to satisfy customers so that they remain customers, and give us enough of their hard-earned cash so that we may live if we manage to keep our costs down by eliminating our own wasteful activities. Toyota’s basic strategic assumption is “one time customer, lifelong customer” – the idea is that if you never lose a customer when they renew their purchase, you can build a stable, sustainable, profitable growth.

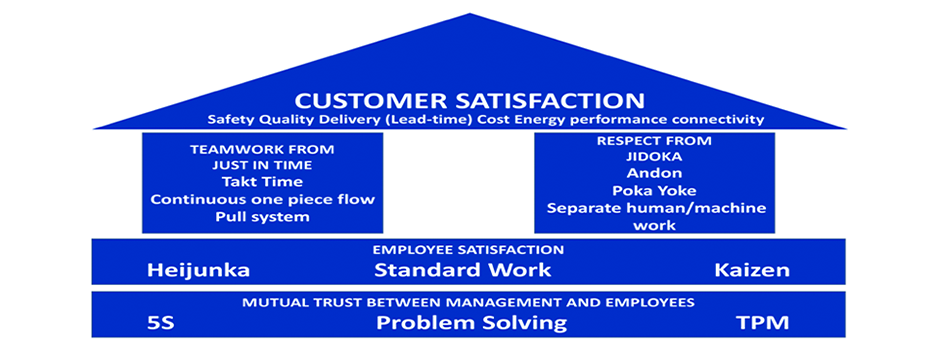

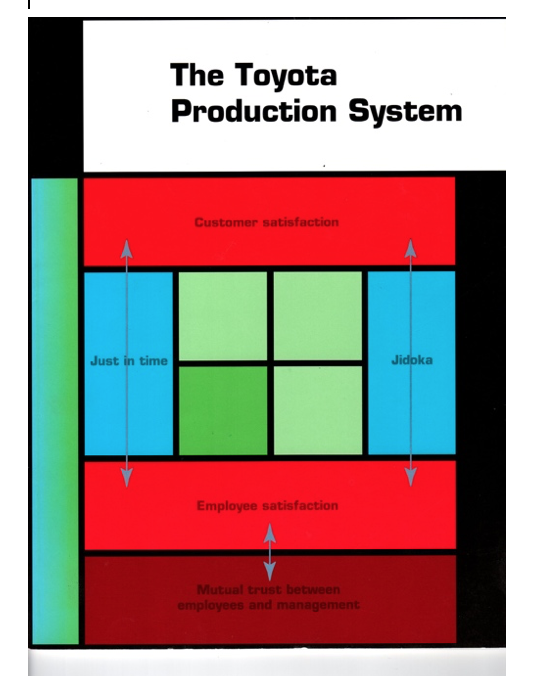

But how does that work? Ideally, a model should be expressed in the form Y= f(X1, X2, X3..), with a clear output (Y), various inputs (X1, X2, X3) and a function f, a mechanism that explains the causality. I doubt we could ever go into the mathematics of it, but if you collate the various versions of the TPS house, the model is surprisingly clear.

Let’s Build A House

First, customer satisfaction is a function of safety, quality, delivery (through flexibility), cost, and more lately energy performance and connectivity. The logic is consistent with other research, and postulates that if you improve safety for both customer and employees, quality, delivery lead-time, cost, energy performance and connectivity, you’ll increase customer satisfaction.

According to this model, the basis for reaching customer satisfaction is… mutual trust between management and employees. This output is achieved concretely by 1) 5S, 2) Problem Solving and 3) Total Productive Maintenance (TPM). The function, the model, is that if employees are supported in taking control of their own workplace through 5S, if they are constantly developed in being more autonomous in problem solving – and thus more confident in their ability (and the company’s) to do so – and if, finally, all equipment works when needed and is available because management has set the enabling systems in place to make it so, then employees feel confident they can succeed in doing their job because management is doing its part. These activities create the basic stability that teams need to work confidently.

I’m not discussing whether this is actually the case, and whether other variables should not be taken into consideration, such as hiring, training, commitment to values and so on and so forth – obviously they are important as well. But the engineers who formulated the TPS house made a stark choice in where to look for mutual trust. They privileged ownership of one’s workspace, autonomy in problem solving, and having enabling processes that work without second guessing.

Mutual trust between management and employees is a function of doing the following things well: 5S, problem solving, and enabling TPM.

The next layer of the theory is that, on the basis of the mutual trust created by basic stability, customer satisfaction derives from employee satisfaction.

In the lean theory, employee satisfaction derives from heijunka (leveling, fractioning, mixing) to avoid variations in workload and overburden, standards so that there is a known way to do repeatable work, and kaizen to get involved with studying waste and looking for new ways of working.

This is surprising but consistent with other learning theories. Firstly, it makes sense to think that workload management is key to employee satisfaction. And, that keeping a leveled load helps people make it through the day (or conversely, the way many managers overload people and then have them wait idly is massively discouraging). Secondly, action learning theory describes learning as a mix between programmed knowledge (knowing what is known) which is all about learning standards, and then insightful questioning, which is precisely what happens during kaizen activities.

Essentially, this states that if employees have a reasonable workload, understand what is expected of them and how to do the job well through clear standards, as well as seek to improve the wasteful aspects of their work and are supported in their improvement effort, they’ll find their jobs satisfying, because they’ll feel both safe and have space for excitement and taking control over work.

Clearly, this layer only makes sense if the previous one – mutual trust – creates solid enough conditions for employees to commit to both learning known standards and questioning them through kaizen.

Now, we can perceive that there is a link between employee satisfaction and customer satisfaction, but that link is far from certain and needs a heavy dose of orientation. This is what the two pillars Just-in-time and Jidoka create in the system.

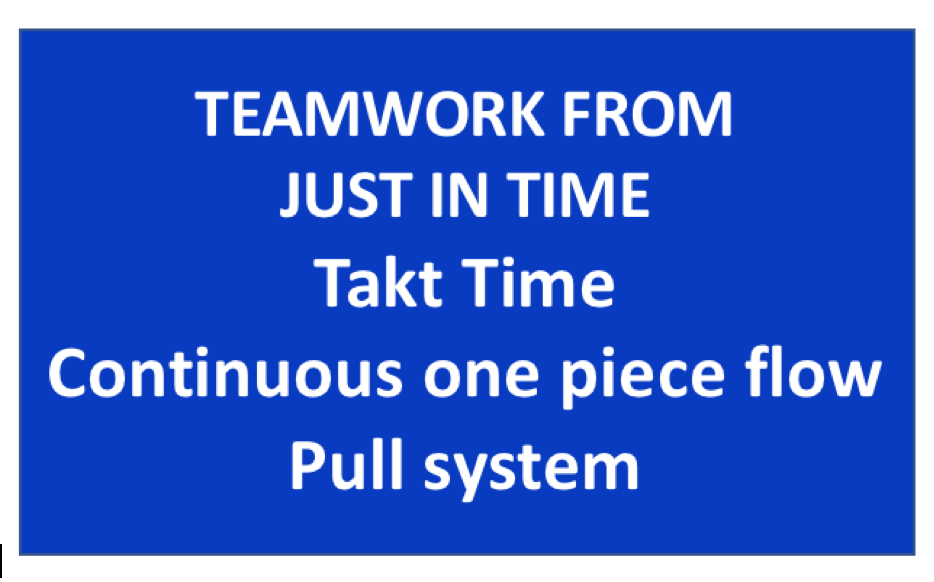

Just-in-time’s output is greater cooperation between function as was originally envisaged by Kiichiro Toyoda. Constantly seeking to reduce lead-time puts pressure on functional processes to better coordinate and require less capital (through greater flexibility and cooperation). This output is achieved by takt time thinking, seeking continuous one-piece-flow and pull systems. The pull system – and its ultimate aim of continuous one piece flow at takt time is what creates tension in the system by taking out all reasons for stagnation time, whether rework, batching, poor scheduling or any other problem. Increase in teamwork is produced by better matching takt time, getting closer to continuous one-piece-flow and pulling more flexibly and rigorously in smaller batches.

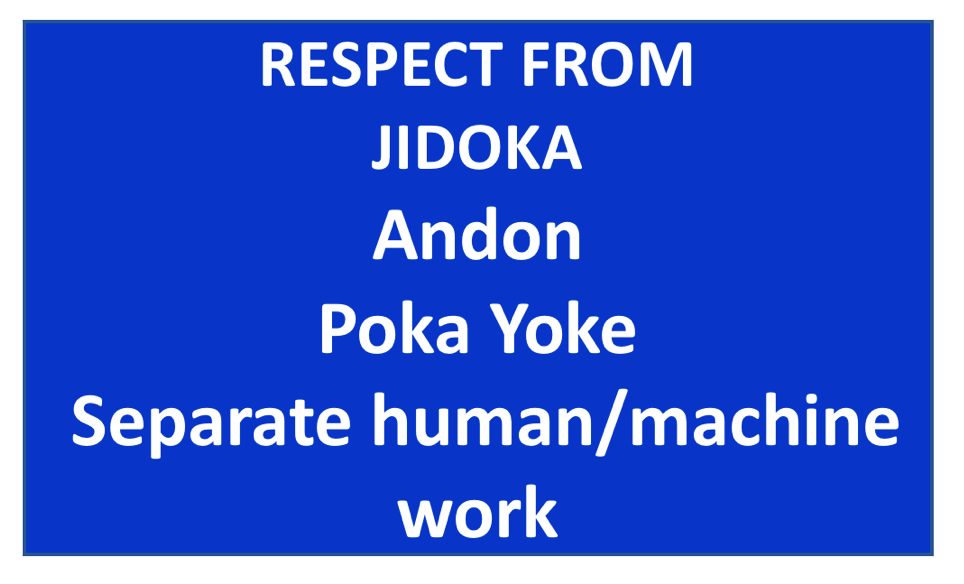

Just-in-time, however, creates relentless tension on work and reveals the endless problems reality throws in at the best thought plans and processes. Teamwork will fall short if employees have no way to react to overcome these obstacles – they’ll just get discouraged. The second pillar is about respecting each person’s real-time difficulty by the “Jidoka” (built-in quality) approach of stopping right away rather than carrying on with faulty work. The first input of the built-in quality is andon – calling whenever one encounters a problem and expecting management support in seconds (seconds, not minutes, hours or days). The second input is poka-yoke, inventing clever simple system to avoid errors in the first place. The third is “separation of human work and machine work” – making sure equipment is designed to run autonomously at the push of a button and no team member has to stand and watch a machine operate.

Taken together, these two pillars generate the teamwork and respect which links employee satisfaction and customer satisfaction through a constant pressure to reduce lead-time and through turning the chain of command into a chain of help to be able to support employees on the spot with all the problems the tension of just-in-time is likely to create.

As a whole, this creates a full model about how to achieve customer satisfaction from employee satisfaction, through teamwork and respect, on a basis of mutual trust between management and employees.

There are several versions of the TPS house, and no two versions are exactly alike. The one I’ve presented is drawn from a 1996 booklet issued by Toyota’s internal “lean” office at the time (Operations Management Consulting Division) detailing the TPS in English.

This is not about “truth”, but about the need to research the thinking underlying the lean model ever more deeper. Beyond the folklore, beyond the reduction by this or that writer, lies a structured system of thought that links conditions, such as mutual trust between employees and management and employee satisfaction with a market outcome, customer satisfaction.

What is “lean,”then?

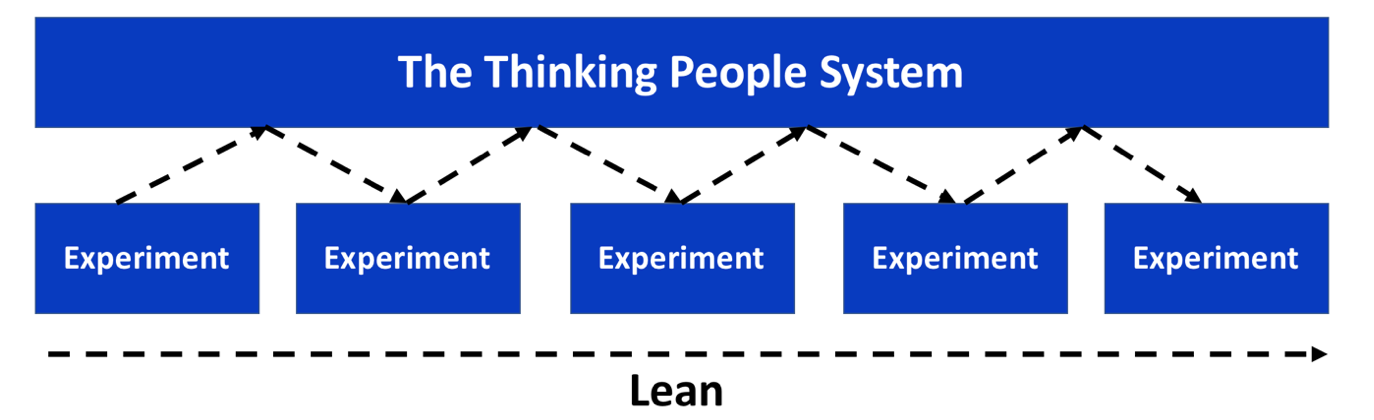

Well, within that outlook, lean is the result of constantly observing real conditions on the gemba, going back to TPS (the Thinking People Systemas it is also called by Toyota veterans) for inspiration, thinking about something else to investigate and try, looking for the impact, going back to TPS and so on and so forth. There is nothing to apply or to implement. There is learning in the form of familiarizing oneself with what TPS can signify for each company, away from Toyota, the automotive industry, or Japan. TPS remains an inexhaustible source of inspiration and “lean” is the sum of these inspirations.

It’s part of the game for each “lean” company to develop its own lean system in the form of its own typical problems/typical solutions it needs to pursue in order to become more competitive, and we know several other companies such as Amazon, Boeing or Zara that were successfully inspired by Just-in-time. But each company is just one case. TPS, on the other hand, has been field tested on numerous plants, countries, operations, from design to production to service, and although it evolves and there are several slightly different versions of it within Toyota itself, its basic logic, the underlying model of learning to better solve problems through visualizing them, trying new stuff and thinking more deeply about what happens, remains solid and stable.

Learning is not applying once and going home. Learning is trying again and again until you get the hang of it. Only then do you start discovering the subtleties of it. Progressively you acquire mastery as you explore the true depth of the object of learning. Which is why practicing lean at CEO level involves writing the TPS on a notebook, or a paperboard, or a whiteboard time and time again until, progressively, the understanding of it a interrelated system, as a full theory of business permeates the vision of the company as it is, and influences ideas of the company as it should be – leaner – which means satisfying all customers (so that they keep doing business with us) by constantly offering them better products, by developing every single employee in better handling their job purpose, reaching out for high standards, being autonomous in problem solving, and showing ingenuity and initiative in seeking a better way to do what they currently do.