While outsiders might consider the core competence of Toyota to be eliminating waste through TPS, Toyota executives know that their most valuable practice is their dedication and skill in developing leaders. Toyota leaders serve a higher purpose of contributing to society, local communities, and team members. They create challenging goals for the business to survive and lead with passion to achieve those goals while simultaneously developing people. Process improvement and people development go hand in hand for them.

This True North set of beliefs shapes a model of leadership that deeply informs the way the company does business, creating leaders who achieve the organization’s goals both in results and in the way people work to achieve them. They multiply their impact by developing leaders who develop other leaders with a scientific mindset in working systematically toward any goal. Quality, cost, delivery, safety, morale, and environmental harmony are all goals that require the same energetic approach to systematic kaizen. It is a skillset and mindset that Toyota leaders spend their lifetimes cultivating.

I often contrast Toyota to Western companies. In the United States, we value the rugged individualist as CEO — someone who is charismatic and loudly articulates a bold vision for the company. This heroic figure secures the right executives, who either make the vision happen or are pushed out. Since our CEOs tend to be portable, they typically take some recipe that previously worked for them and impose it on whatever new companies they take over. When coming to a new company, they often talk about fixing a “broken culture” by installing their new performance culture. This approach often includes bringing in consultants they have used previously to build the leadership team and help drive the new culture.

Toyota grows its leaders from within to live and breathe the culture.

This approach aligns neatly with what Jim Collins describes in Good to Great as “level 4 leaders” (in a hierarchy of five leadership levels). They can drive a team to work long hours singularly focused on the (usually financial) goals set by the top, but this goal achievement does not make the company great. All of the 11 Western “great companies” he cited were what he called level 5 leaders, who resembled what I observed at Toyota. His insights provided some validation that what I recognized at Toyota was not unique to one Japanese company. His 11 great companies experienced exceptional growth and superior stock market performance, especially compared with 11 average competitors and six “unsustained” companies that temporarily appeared great but then declined.

The level 5 leaders’ characteristics include the following:

- Intense professional will, yet personal humility

- Understated, yet fearless

- Transformational leaders

- Dedicated their lives to building an enduring and great company

- Selected the best people for jobs, even bypassing family members of the founders

- Founded the company or grew the organization from within

- Looked in the mirror and assigned self-blame, looked out the window to assign credit

- Obsessive about knowing their business in detail

- Brutally honest about reality, even when it is bad news

Voila! You have a Toyota leader. Like Collin’s great companies, Toyota grows its leaders from within to live and breathe the culture. Almost all Toyota leaders are hired as “freshmen” and stay with the company until retirement. Overseas operations often hire from the outside when necessary, but for the most part, grow from within.

But doesn’t this type of culture become stale? Toyota certainly wants a stable culture, and the underlying values have not changed since Sakichi Toyota founded his loom company. However, that stable culture focuses on developing exceptional leaders who are passionate about pursuing excellence and achieving even the most audacious goals. Creativity and innovation are expectations for Toyota leaders.

TPS master and Ohno disciple Nampachi Hayashi explained it this way:

“There is no magic method. Rather, a Total Management System is needed, that develops human capability to its fullest capacity to best enhance creativity and fruitfulness, to utilize facilities and machines well, and to eliminate all waste.”

Approach Breakthrough Goals Scientifically

Toyota’s model of humble leadership is rooted in a deep understanding of the gemba, testing the next idea on the way to the challenging goal. Steven Spear gave a vivid example of how leaders are trained to do this, as summarized in the new edition of The Toyota Way. He recounts that an American called Dallis (pseudonym) was hired in and trained by a TPS master. Dallis had two separate master’s degrees in engineering and was used to being a hotshot. However, his approach was challenged when he was assigned to an engine plant where he had to put his head down and get his hands dirty to reach challenging goals focused on equipment uptime, productivity, and ergonomic safety.

The master asked him to achieve these goals through short, rapid cycles of experimenting. Dallis struggled to reach the goals and came close. He was then sent to Japan to do the same thing, competing, in this case, with Japanese team leaders working on similar projects. At first, the Japanese won, generating far more ideas and implementing more of them. But eventually, he got the hang of it and met his objectives.

This patient, grounded, disciplined approach is what Toyota is looking for in a leader and how they teach it — humbleness, persistence, and continual learning.

After this humbling stint in Japan, Dallis returned to the United States to continue working on equipment uptime, exceeding the original goals and achieving 99%. Dallis learned he was indeed not a hotshot, and he had a great deal more to learn. He also learned the value of working on real problems at the gemba with a qualified coach. Perhaps most importantly, Dallis learned respect for people. He could not have achieved any of the goals without the help of dedicated team members.

Dallis’s lessons about the process of learning was later codified by Mike Rother in what he called the improvement kata in his Toyota Kata. This iterative process of learning your way to a goal involves many small steps, with the ultimate goal of a breakthrough on a big challenge. Dallis learned that his initial thoughts about reaching the goal mainly focused on big solutions and were probably wrong. Instead, he discovered that he could learn more by trying things and learning from successes and failures. His coach helped him see any failure as no more than something that did not work out as expected—something to learn from.

This patient, grounded, disciplined approach is what Toyota is looking for in a leader and how they teach it — humbleness, persistence, and continual learning. Toyota leaders all over the world go through similar training, and the training never stops. So, every leader has another leader coaching them to achieve ever greater breakthrough goals while they are coaching others. That’s why the culture is in a state of constant renewal.

How Can Companies Outside Toyota Develop Lean Leaders?

A popular tool these days is leader standard work. In particular, for senior leaders, continuous improvement staff will ask questions and guide the leaders through the plant while addressing the questions. The questions act as a checklist of what to look for. Busy leaders may resist spending the time doing this, but in my experience, they find it both enlightening and energizing.

Leader standard work is a kind of kata, which in the Japanese martial arts are exercises to practice a particular skill repeatedly until the master instructor is convinced you are doing it correctly and has become a new habit. Mindful gemba walks are practice routines that are most valuable when done with a skilled coach providing useful feedbacks, primarily by asking questions.

This type of leader standard work is one useful kata to get started, but it is not the endpoint. Think of a beginner piano student playing scales or simple tunes to learn how to put their fingers on the right keys. They are expected to practice repeatedly and checked by the teacher until they get it right, but the result is a starting point—a basic foundation for developing the skills of playing more complex pieces.

Mike Rother calls his improvement kata and coaching kata “starter kata.” They are to begin to exercise your mental muscles to lay the foundation for higher-level scientific thinking.

Leader standard work is a kind of kata–exercises to practice a particular skill repeatedly until you are doing it correctly and it has become a new habit.

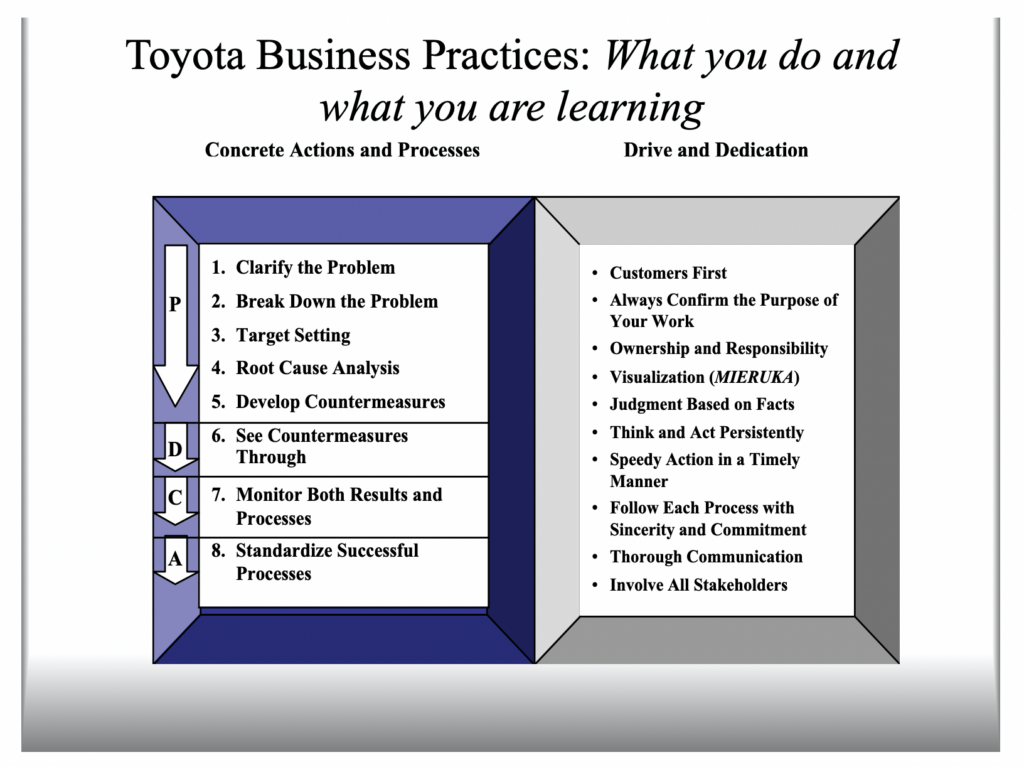

Toyota Business Practices (TBP) is Toyota’s kata. The company introduced it with the usual approach of long-term thinking, deeply developing people through on-the-job practice. On the surface, it is an eight-step problem-solving process that follows plan-do-check-act (PDCA, see the chart below). While this method is fairly straightforward and not hugely different from other problem-solving approaches, the purpose is not to provide a standard method to be applied to all problems.

TBP was introduced mainly as a teaching tool. Toyota had developed The Toyota Way 2001 and wanted a way to put those principles into action. The purpose of TBP is to get the student, a leader, doing something real that allows the student to be coached on the job. Perhaps more informative than the eight-step process are the ways of thinking the coach is working to develop in the student, listed under “drive and dedication.”

Thus the paradox is that while the student is doing one thing, they are learning something else. Following the eight steps represents a concrete way for the student to be challenged regarding the core of Toyota leadership. As the student-leader works toward the challenge, the coach has the opportunity to observe the leader in practice as they define the problem, collect information, interact with various people, lead meetings, set priorities, develop creative ideas, follow through to complete tasks, and much more. All of these activities present opportunities to coach the leader.

What Does This Mean Outside Toyota?

A company that has hired leaders from many different places with different cultures and has not dedicated time and effort toward developing their skills cannot just jump into something like TBP and get the same results as Toyota. Nor are they likely to dedicate more than a decade to cascading this training from senior executive levels to workgroup leaders, with each level becoming a student and coach.

It is realistic and possible to develop lean leaders at all levels given time, persistence, and the dirty word patience.

The starting point is to take developing leadership seriously and recognize that short training courses or workshops or coaching leader standard work for a short time will not fundamentally change how your leaders think and act. At best, the people being coached will become more aware of certain things and develop a new vocabulary. But when faced with a real situation, especially under stress, they will likely revert to what comes naturally.

Nor is the answer to fire existing leaders who do not get it and hire fully-baked lean leaders. You want to develop your culture deliberately, and outsiders will never deeply understand your business or culture. It could be useful to hire some people with deep lean experience whose values are compatible with your desired culture, but primarily to coach others.It is realistic and possible to develop lean leaders at all levels given time, persistence, and the dirty word patience. You need to start at the beginning, and Rother’s kata are a great place to start. At a minimum, developing a new way of thinking and acting requires repeated practice with repeated coaching feedback over long periods of time. It does not require that you follow the improvement kata model or TBP. You can develop your own kata. But the purpose of the kata is to practice healthy habits and methods until they become natural, and then you move on. Practice kata to achieve something broader: developing leaders who approach challenging problems scientifically with respect for people. It is a long-term journey, endless really, and you will continue to learn, refine, and develop your approach.

Improvement Kata/Coaching Kata

Develop Scientific Thinking, a Foundation of Lean Management in the 21st Century.