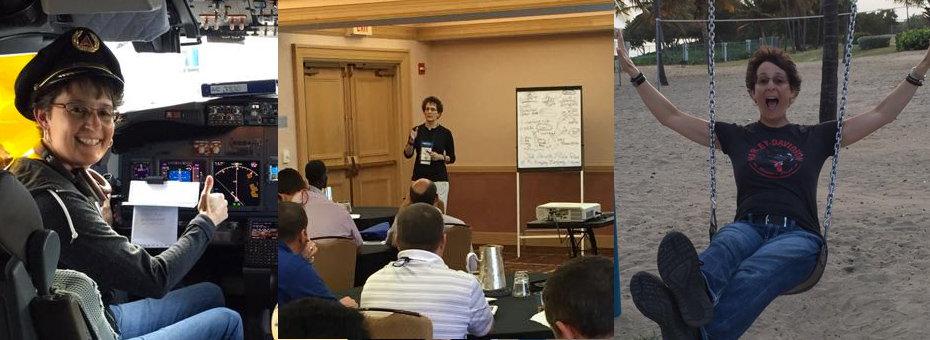

Toyota veteran, LEI faculty member, and Lean Post contributor Tracey Richardson has written for the Post on problem solving, A3 thinking, leadership, lean culture, and visual management, among other topics. We sat down with Tracey to talk with her about her approach to both teaching and writing with the aim of learning more about her process of sharing lean thinking with others (so that they might better achieve their business and organizational goals).

What led you to not just practice lean, but teach?

Having the opportunity to learn from Japanese trainers in the early days at the TMMK plant (1988), sparked a passion for me to go into training and development not just for Toyota but outside as well. I’ve personally experienced how successful the “thinking” can be, how putting people development (respect for people) first and foremost can be. I’m also a very hands on visual and kinesthetic learner, so getting to go to many gembas across industries and share with people all the dynamics around problem solving and culture is priceless. As my trainers would say, I’m giving back and also “sharing wisdom.”

What seems to work best in teaching lean ideas and practices to people who are just getting started?

I try to lessen the “tool talk” and “lean talk.” I think when the labels are more important than the process and thinking behind it, people can lose the true intent of why they are doing something. It often becomes more about outcomes, return on investments, measuring the wrong things.

“When you make a decision to change the way you do business, it should hold you accountable for certain leadership actions – new leadership behaviors that engage and empower team members to want make a difference in their daily work.”When you make a decision to change the way you do business, it should hold you accountable for certain leadership actions – new leadership behaviors that engage and empower team members to want make a difference in their daily work. If people have an ability to impact key performance indicators for the organization, then they suddenly have a new line of sight. They understand their role in the organization or what their role could be. In other words, folks need to be supported in visualizing their own gaps in performance and then they need to want to learn more. That’s how I learned. I had a responsibility to the company to contribute to the job security for then entire company as well as myself.

In the beginning we didn’t call it anything but our job. When I teach, I try really hard to help people understand that investing in people and teaching problem solving – these are the actions of leadership. It’s about recognizing nonvalue-add activities and creating value in every dimension of each functional area from order to customer. That is truly Lean to me.

And what’s been most valuable for you about putting what you’ve learned into writing?

I like to consider myself a practical instructor using past lessons to teach others to translate the learning into their world. I love the classroom. I try to hit all the learning styles and have fun doing it. I think writing can be just as impactful if I can grasp the readers’ attention like I do in class. I truly try to write as I would tell a story in class. So far people have given me good feedback, but I’m always learning, so feel free to give me more so I can improve how I share!

What’s the hardest about writing?

I’ll be honest, writing is not easy for me. This goes all the way back to when I was a kid. It takes time for me to extrapolate what’s in my mind and put it into words. When I’m in the classroom I’m very animated and theatrical. If you taped my arms down I don’t think I could talk! My fear or difficulty with writing is that I will miss some key translation points because I can’t always put the depth of my learning experiences into the right words. I’m thankful to other authors and writers who share their wisdom, and I’ll continue share what I can. It’s a process like anything else.

What are you looking forward to seeing in the lean community? What new opportunities and challenges do you see ahead?

This is a good question for all of us who are trying to improve how we teach others and share ideas. I think a really important thing to think about is how organizations measure how they are doing. We often find the scales are shifted on the heavy side of results-oriented indicators which are historical in nature. I’d like to see the lean community shift that a little – shift expectations a little – in the direction of leading more predicative indicators so people can make a difference before they get the “3 month report”. It also puts the focus on processes and standards, which is important for continuous improvement to actually happen and be measured.

People get so focused on outcomes and not the processes that get them there. Embedding effective gemba walks along with good visual management – these are also important factors for longterm growth and sustainability. I think our challenges as a lean community reside in raw discipline and accountability to practice the right thing even when it feels uncomfortable. My trainers would tell me if I’m too comfortable everyday, then I’m probably not learning.