Dear Gemba Coach,

What’s your opinion on setting specific criteria before brainstorming countermeasures? I’m thinking of criteria that create a challenge, but stimulate a creative solution, e.g. cost (no money, or keep within budget), time (by this date), floor space (create smaller footprint) etc. Then try the solution and check. Regarding creativity, we try to strive for multiple countermeasures for causes where possible and score them on effect, effort, cost, morale etc. before taking action.

Sure, having a clear direction for improvement absolutely makes sense. It’s the brainstorming for solutions I’m not so certain about.

Let’s go back to the gemba for a second. I just got my car back late from servicing at the garage. It was jammed with waiting cars. Clearly it had a throughput problem. If we’re doing lean, we’ll be looking for a solution that reduces the inventory of cars whilst reducing the total cost of doing maintenance, responding better to customer specific demands, and making tasks easier for the mechanics.

If we start brainstorming about possible countermeasures, everyone and their dog will have ideas. More dangerously, the boss will have ideas as well. More often than not all others will wait to hear what the boss thinks before positioning themselves. Everyone is in fact equally likely to be right – or wrong.

Brainstorming – collectively generating spontaneous ideas to find a conclusion to a specific problem – is a technique popularized by a 1950s Mad Men exec. The jury is in by now: it doesn’t work. It doesn’t generate particularly creative ideas, but it gives the group an illusion of its own performance. Nothing like a great brainstorming session to make a group feel good about itself, which is why consultants love the technique.

And bosses: Have you noticed how, when they want to get you to swallow a budget cut, they have consultants lead these great brainstorming sessions in which we’ll magically discover ways to do more with less?

Grasp Don’t Brainstorm

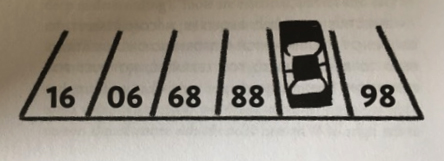

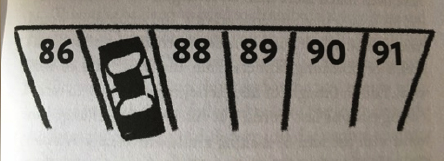

On the other hand, really creative ideas are born very differently. Talented people are those who can look at the same situation as everyone else, but somehow assemble it differently and see a solution where others don’t. My favorite example is the following. Can you guess on which number parking spot this car is parked?

Or think differently:

Talented people don’t do so out of the blue. They reach new ideas by (1) knowing their topic inside out, (2) noticing something that itches their thinking bump, (3) taking an intuitive leap. Mostly, they find problems, not solve them.

The key to creative idea generation is not in brainstorming, spending hours in the shower, or any “serious game” simulation you can dream up. It’s in observing more closely and trying stuff until, to take Art Byrne’s sensei’s phrase “knowledge visits you.”

Put Away the Post Its

The most powerful – and often ignored – part of conducting an A3 is way before thinking of new ideas. It’s in the “grasp the situation” part. As my sensei taught me, list all the reasons why a specific car is not getting out of the garage at the standard/ideal/required time, then do the same for another car, and then another until you have a shortlist of reasons:

- Missing specific parts that are hard to source

- Missing the one mechanic who knows how to perform a specific task

- Availability of car lifts

- Etc.

Etc. is actually the time to get creative. One of my sensei accepted no less than seven hypotheses to start with. And then we had to test them, which meant being creative about a practical test method:

|

Hypothesis |

Test method |

Test results |

Yes/No |

|

1. |

|||

|

2. |

|||

|

3. |

|||

|

4. |

|||

|

5. |

|||

|

6. |

|||

|

7. |

More often than not, the really creative idea came out of the blue – none of the above.

But that’s the point, this kind of creativity is not blue-sky brainstorming, but, on the contrary, getting your hands dirty with then problem itself.

In the garage case, the problem turned out to be an ERP change at one key distributor, which generated a new parts classification that didn’t match the ordering system of the garage and made some parts appear on order whilst the ERP considered the request not valid and threw them away. The cars were waiting for parts that would never arrive. As you can imagine, when he finally figured it out, the garage manager was not happy about it, and trying to explain this to all the unhappy car owners waiting for their wheels.

Create tension on problem solving by reinforcing improvement dimensions and visualizing this in a decision matrix is definitely smart:

|

Proposal |

Safety |

Quality |

Cost |

Lead-time |

Etc. |

Total |

|

1. |

||||||

|

2. |

||||||

|

3. |

||||||

|

4. |

But the key issue is generating really creative ideas, not blue-sky ideas that look good on a post-it but don’t live in the real world. Problem finding is the key skill, rather than brainstorming.