Customer-defined value creation is the first principle of lean thinking—the foundation of a lean enterprise. But how do you know, really know, that beyond eliminating waste and fitness for use, your hard work will deliver a product your customer actually values and will buy?

Well, you could ask them. While this is a good start, it is rarely sufficient and often limiting. You are likely to end up with your version of Henry Ford’s “faster horse”. While you should certainly listen to your customers, the best companies understand their product’s unique value potential better than anyone.

More than a limitation, relying solely on customer input can become a crippling organizational dysfunction. Especially when understanding customer-defined value becomes code for “send out another survey”. Excessive dependence on customer interrogation can lead to an insidious shift in perceived responsibility where you make your customer responsible for your products. Any number of defensive comments like “It wasn’t in the survey data,” or “They never said they wanted that,” serve as clues.

Even translating your customer’s feedback into meaningful actions can be challenging. Vague statements about delivering customer value can become the solitary purview of the sales and marketing team, code for mindless cost cutting, or worst of all, a gluttonous “more must be better” addiction to piling on bells and whistles, hoping to get lucky.

So how can you know your entire organization is aligned around delivering best in class value to your customer? Your product gives you that focus. In fact, it seems incredibly difficult to be a lean, customer-focused organization without comprehensive knowledge and an absolute passion for your “product”. Your product is who you are as an enterprise: it’s your identity.

A company’s products are their most direct connection with their customer, and the embodiment of all their value creating activities (not to mention the lifeblood of the company). At Ford we learned the hard way how important great products are, and it was product focus and passion that fueled our turn around and allowed us to break down functional walls and combine traditional PD and ME organizations into a single global team to help drive our “One Ford” strategy.

Intense product focus provides other, less obvious advantages for a lean enterprise. It gives everyone something tangible to work on—a deep focus that is far more specific than “customer value” (which can in fact be mysterious). And it also gives individuals the opportunity to develop true mastery, an often-undervalued quality that provides the basis for on-going competitive advantage.

To become product focused, companies must understand, better than anyone else, the critical product/service attributes that truly matter to their customer. They must align their product attributes, manufacturing and operational processes, and quality priorities, accordingly. In this way, product/process development should bring the entire company together as an aligned, customer focused, lean enterprise.

To become product focused, companies must understand, better than anyone else, the critical product/service attributes that truly matter to their customer.

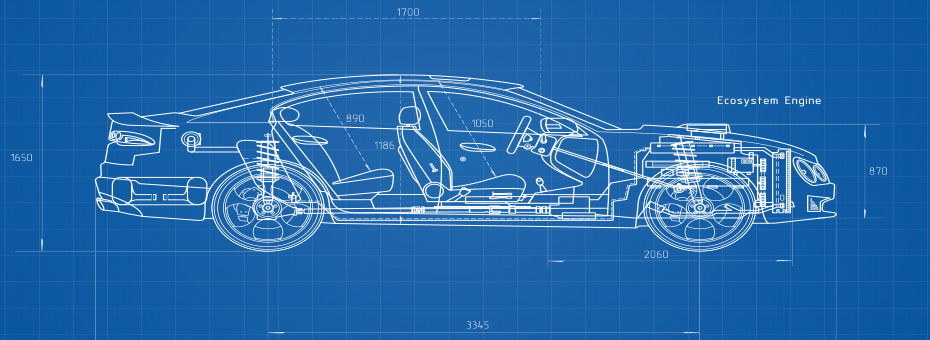

A lean product/process development process is built on this deep organizational understanding and starts with a study period, or Kentou: a critical learning phase during which the organization understands and agrees on both what they are going to make and how. It begins with product immersion. The Chief Engineer (CE) and a small team undertakes to understand everything about their product: its uses, cultural nuances, operating environment, competitors, manufacturing process, everything.

As you might expect, they start their learning at the gemba: hands on and face-to-face. Going to manufacturing, key supplier and testing sites, participating in competitive teardowns, meeting with third party evaluators, talking to customers, even looking outside of their industry, and most importantly, using and watching the product’s use in the field.

There are many great stories about CEs and their teams from Sienna, to Lexus to Mustang who were incredibly successful in this endeavor. The next step is to communicate to and align with the rest of the organization. This starts with the CE Concept paper outlining both quantitatively and qualitatively his or her vision for the new product. But it can’t end there.

The Functional Teams, masters of their respective disciplines and passionate about the product, begin to study what it will take to deliver this product with excellence. They work cross-functionally, with the CE, examining, analyzing, testing and eventually agreeing on a way forward. (Lest the more skeptical amongst you roll your eyes at the idea of a cross-functional utopia, I can assure you that this process is ripe with robust dialogue, debate, tension, and conflict as passionate professionals drive for a truly great product). But in the end the product is the mediating factor. What’s right for the product? The primary responsibility for this, the tiebreaker belongs to the CE. Huge responsibility? You bet. This is why it’s not easy to create good CEs, but that’s a topic for future post.

The result is not only a plan for a new product with unique and significantly expanded value potential (read “insanely great product”), but also a powerful organizational focus and commitment to delivering. Plus, a deep understanding of exactly what is needed to create maximum value for the customer.