As worldwide GDP growth increasingly focuses on service-oriented work, we are faced with a question: is Lean thinking a thing of the past, from glorious manufacturing times in the late 20thcentury? Are Agile or Design Thinking taking over, to match changed patterns of digital and service development? Or, on the other hand, is it possible that Lean is still the best approach to address ever-more-complex human endeavors today?

Lean thinking is not dead, argues Sandrine, who shares the story of a startup resorting to Lean thinking to avoid the big company disease as it scales up. Lean thinking is universal, claims Lucy. She suggests that you step out of the “Lean as a toolkit” frame and see instead how perfectly it applies to our modern world as it focuses on customer value, respect for people’s capacity to continuously improve, and action learning. Lean thinking addresses variability in any activity, says Anne Lise; just make sure you sincerely want to improve the service to your customers, by developing the team’s skills and re-considering your managerial role as the first support for that development.

Lean thinking is wall-to-wall, Cécile demonstrates, from value creation to cost reduction, and there is as much Lean thinking in product development and customer retention as in manufacturing. Lean fosters collaboration, argues Rose, who sees in Lean a unique opportunity for support functions to collaborate along the value chain. Jean expands on this and recounts a detailed story of Lean collaboration in an order entry process, where they reduced lead time, reduced touches, reduced errors, reduced waste. Catherine offers another angle: Lean thinking is designed to make you see and understand the wrong assumptions you made, help you shift your corporate strategy as you unveil challenges, and learn from genchi genbutsu and problem solving.

****************

Sandrine Olivencia

Sandrine Olivencia

In Europe and the US, more and more digital startups are turning to Lean as a growth strategy, and they have impressive stories to tell.

Yesterday, JB, the energetic head of UK-based InsurTech Veygo, shared his exciting story at a Lean conference. Lean has helped him increase the conversion of his flagship insurance application by 60%, contributing to the company’s fast growth over 12 months. He also described how lean completely transformed his vision of leadership, from a “Rambo” style of management, i.e., traditional “command-and-control”, to that of a “gardener” who nurtures and supports. JB wants to create a safe work environment where people are open about problems and show initiative in improving customer satisfaction. He knows that this is the condition for steady and profitable growth, and he has chosen lean to make it happen.

JB’s story is far from unique. In Europe and in the US, more and more digital startups are turning to lean as a growth strategy, and they have impressive stories to tell. Their motivation? The need to build healthy companies which can grow at the speed of light, yet remain highly profitable and attractive over the long haul. This is all the more crucial since the main recruitment targets of startups are millennials, a generation that demands a sense of purpose, strong social connections, and opportunities for personal development. They will leave a job as quickly as they have taken it if they don’t get what they want, or if the company rigidifies. /p>

A startup must grow fast if it is to last, but growing fast brings its own share of problems. Any startup can transform into a “big company” in the blink of an eye. And as soon as a startup becomes “big”, the risk of losing competitive advantage increases exponentially. I see many young companies, even those with only 20 to 30 employees, already showing the symptoms of big company diseases:

- They spend precious energy on making their own people comply with processes, rather than encouraging them to find new ways to better satisfy customers.

- They develop a silo culture where local priorities take on more importance than the company’s global interest.

- They build a management system that suppresses initiatives rather than supporting people development.

- They become preoccupied with delivering their current slate of products, and stop looking for new opportunities.

I find it quite surprising to see the dynamic, 30-something CEOs of digital startups making old-fashioned decisions, such as creating and imposing rigid standards on their employees. What makes a startup more efficient (and fun!) than a large company is that everyone spends their energy on finding new, exciting ideas to find and please customers.

In a relatively open market the risk of slowing down is low, so companies focus on racing towards success without an ounce of concern, probably with good reason. One has to strike while the iron is hot, right? Eventually, however, newcomers join in and start feeding off the same pie, and soon the demand reaches its natural limit. This is the curse of the hype cycle. If a company has not built up its capabilities to learn and adapt to changing market conditions by the time it reaches the peak, it will start sliding downhill soon after. Lean, when adopted as a full-blown strategy for sustainable growth by company leaders, is the perfect remedy for curing big company diseases and breaking the curse of the hype cycle.

How so? By allowing leaders to create the conditions for everyone to participate in quality improvement, cost reduction and value creation, and then investing the lessons learned and excess capacity in designing new solutions to resolve today’s problems. Leaders of startups on the rising side of the hype cycle, can learn to apply the Toyota Way and TPS in their own context and teach them to their managers, who will then teach their team leaders, and so forth. JB started by learning about his customers’ pain points, preferences and complaints, while engaging his team of managers. Every week, they listen to calls and try to understand who their customers are, what problems they are trying to resolve, and what the product is not delivering. This regular exercise helps them remain focused on the customer instead of their internal problems and politics. As a result of this exercise, JB decided to make drastically improving quality a goal for the whole company, and he worked hard to engage his teams in the process. The results speak for themselves. When quality becomes the main focus, customers become promoters, and sales take off.

There is no doubt that lean should not be seen as just a manufacturing approach. The digital startups of today are the companies that will shape tomorrow’s business world (as some of them already have). The leaders who have the guts to adopt Lean as their strategy have a much better chance of escaping the hype cycle and staying in the game.

****************

Lucy Liu

Lucy Liu

Understanding of Lean comes from practice. My learning and practice in Toyota Australia convinced me that Lean could be applied to every function and every process with everyone.

There is a common recognition that Lean was originated by Toyota and induced to the world 30 years ago by The Machine That Changed the World (Womack, Jones, and Roos). Due to the enduring success of Toyota over many decades, the management thinking and practice of delivering this result has been the envy of many organisations around the world.

The early stage of application of Lean was largely in the automotive sector, then, gradually moved to other manufacturing sectors across the globe. As the Lean movement continued to expand, it has spread into a wide spectrum of industries such as Health Care, Mining, Education, Finance, Restaurants, Hotels, Software development, etc. Due to the different levels of exposure, understanding, experience and degrees of success, there is a wide range of perceptions with individuals, organisations, and industry leaders on the relevance and significance of Lean. Below are a few perceptions I have found:

- Perception one: Lean is from the Toyota Production System (TPS), hence it would only work for the Automotive industry. The Lean tools are designed for the repetitive work/processes.

- Perception two: Lean is useful for the manufacturing industry because it is about making things Just-In-Time. As such, it is not so relevant to the service and other non-manufacturing industries.

- Perception three: Lean can be applied in any industry and any process. Everyone could apply the Lean thinking every day.

After my 30 years of Lean learning and practice journey, I am convinced that Lean is for every industry and every one.

Let’s start our argument from setting a common base on Lean. Firstly, its purpose is to provide maximum value to customers through the elimination of waste. Secondly, the cornerstone of Lean is the respect for people and continuous improvement. Thirdly, Lean is an action learning process with the aim of building problem solving capability. If these three are the key principles of Lean, then we could see why it is applicable for any industry.

If we go deeper to understand the origin of Lean which is the Toyota Production System, it consists of two pillars: Just in Time (JIT) and Jidoka (Error Proofing Mechanism). The aim of JIT is to provide the right product or service to the customers at the right time in the right amount. Jidoka is to ensure that only good quality product or service is delivered through a built-in quality mechanism and any defect would be detected, process stopped with speedy problem solving. The deliverables out of these two Lean pillars are certainly needed by any business in order to maximise value creation and customer satisfaction.

We could use our own experience to explain how JIT and Jidoka can be applied in the service industry. When we go to a restaurant, we expect our exact order to be delivered at the right time (not too early, not too late) in the right quantity and quality. When we go to the airport, we don’t want to be waiting in a long queue. Stagnation in the process frustrates us. When we go to the hospital, we hate to waste time in the waiting room and expect no errors on any procedures or medication. We could create an endless list of examples on how JIT and Jidoka could help us to gain better service and hence improve our daily life experience.

I think Lean penetration is an evolving and never ending journey. Its origin could make some people feel that Lean is best suited for the automotive or manufacturing industry. The first two perceptions mentioned in this article could be the result of focusing on the Lean tools only, without understanding the purpose, principle and the essence behind the tools. I believe as the Lean community gets bigger, wider and stronger, more and more people will change their perception and promote Lean in many other industries. It is only a matter of time and effort.

Understanding of Lean comes from practice. My learning and practice in Toyota Australia convinced me that Lean could be applied to every function, every process with everyone. This also includes product development, start-up and shut-down of a business etc. The closure of the Toyota Australian manufacturing operation in October 2017 was the best case of Lean shut-down where respect for people and continuous improvement was applied throughout the entire process. Jim Womack also produced an impactful article on the “lean shut-down of Toyota Australia” based on his observation of the process.

While I started my learning of Lean at Toyota 30 years ago, I also have had the opportunity of promoting Lean in a range of industries outside the automotive and manufacturing areas. I have seen when the lean principles and practices are applied with consistent leadership direction and persistent application, successful stories have followed.

The more I’ve learned, and the more involvement I have with a wider range of industries, the stronger belief I have that Lean is not just for manufacturing.

****************

Anne Lise Seltzer

Anne Lise Seltzer

What is important for me is the real intent behind the Lean tools and concepts: do we want to improve the service to our customers?

I often work with teams and managers in the service and office world who do not necessarily know where Lean comes from, nor that this approach was born in the industry. I am, as a consequence, rarely confronted with the famous “hey, we’re not in industry, it won’t work.”

But I will more often hear: “In our activity, it’s not the same, it changes all the time, so we can’t do like others”. And this starting point is actually very interesting in terms of Lean. It suggests several subjects that are at the heart of a Lean approach: variability, standards and flow control.

In the industry, those topics are well known and Lean has offered a clear approach to solve them.

In the services and office, however, questions regarding variability come up again and again, when discussing workload, or the ways of doing one’s job, as if it were almost an intrinsic component of the activity. In these environments, each situation is deemed different, requiring a dedicated processing mode. For example, two clients cannot be treated in the same way. And it’s true, every customer is indeed different! Or, there are peaks in the workload at certain times of the month that require you to abandon everything else for a few days to be sure to keep the dates. And it is true that there are peaks in expenses at certain periods, or that payroll tasks pile up at the end of the month or accounting controls at the end of the period in a financial department. But nevertheless, is it really impossible to have common ways of dealing with customers or to have more collective control over the situation to level the load?

In Lean, it is well known that variability (Mura) results in overload (Muri) and waste (Muda). Aren’t we exactly in the same pattern here? Should we be satisfied with these uncontrolled situations without trying to do something?

If we dig a little deeper, what is indeed behind these situations, particularly in the context of customer or supplier portfolio management, is very often the fact that everyone works in their own way, sometimes according to their own criteria of quality and efficiency, rarely very explicit. As long as the work is more or less done in the allotted time, people are allowed to do as they please. Without often giving them a vision of the global activity flow because it is hidden in computers and therefore made invisible to everyone, making it difficult to see if the activity is at the right tempo (takt time) to deliver on time what needs to be delivered.

These modes of functioning are not only disrespectful for people, because they leave them alone to face their problems, but they also make organizations very fragile. The slightest absence of anyone creates stress in the teams, with everyone wondering how they will be able to cope with their colleague’s clients, not to mention the stress of the absent colleague when returning from vacation as she painfully takes over.

The Lean approach on these topics will really help address these different topics (variability, working standards, visibility of the flow) and improve globally the performance as teams work on how to:

- Better understand the value the customer expects, what can create it and what can destroy it in our actions

- Clarify the criteria confirming whether you are doing a quality job

- Define together common working methods thanks to standards developed with the team

- Make the activity flow visible to give information to everyone on what is happening in real time, and whether we deliver on time

- Reflect together on how to improve these working methods via kaizen

Because the monthly accounts were being closed under severe stress and with overtime, a team from a finance department decided to experiment with Lean. They started by taking the monthly work topics one by one and placing them on a typical month’s agenda to see what it would look like. This perspective over time allowed them to see their activity flow together and identify the moments when the activity should be distributed differently within the teams or over time. From there, workshops were organized to create new standards and increase the skills of team members on key subjects to better manage the load over the month (VAT processing, charges…), thus avoid wasting time and energy.

After 3 months, the closure was smooth for all and some team members were even able to move on to new functions without destabilizing the quality and timeliness of the monthly reporting.

What is important for me is the real intent behind the Lean tools and concepts: do we want to improve the service to our customers? Do we want to do this by developing the team’s skills? Do we want to consider the managerial role as the first support for the development of our teams by enabling them to solve problems? If the answer is YES to these 3 questions, regardless of the sector of activity you are in, the Lean approach will match your needs.

****************

Cécile Roche

Cécile Roche

There is no bigger waste than offering customers products that are not the right ones, products that they do not want to buy, and that they do not like to use.

We often think of Lean in terms of waste: how to reduce waste, in order to increase productivity. Because, of course, all companies want to increase productivity…

But there are many different types of productivity, some of which are rarely given a thought:

- First of all, customer productivity: what is the re-purchase rate of our customers? Remember that according to different studies, the cost of acquiring new customers is 6 to 10 times higher than the cost of keeping them. Only very satisfied customers are loyal customers.

- Capital productivity: are our investments flexible? How many references by machine? Are we really working with our existing investments to propose our customers a high variety of products?

- Purchasing productivity: are we taking into account the total cost of ownership, not only the immediate price of supplies?

- And of course, labor productivity, which is the very first question that comes to our mind, and that we should summarise by “what is the rate of good products by people?” or “how much customer value does each person create?”

In fact, we want to reduce our costs, of course, but at the same time, we need to increase value for our customers. It is not so easy, because there is a constant tension between these two topics, increasing the value and reducing the costs. No one would tell you, especially not Finance, that growth must be sacrificed to profitability, in other words forget value creation and focus only on cost reduction. But in practice, however, this is often the case: we only deal with the bottom line, forgetting the top line.

Actually, there is no bigger waste than offering customers products that are not the right ones, products that they do not want to buy, and that they do not like to use. If we offer such products, it means that we do not understand what our customers value.

Another big waste for the company is when we are designing products (services, systems…) that we are not able to produce, or maintain, or install, or recycle…at the cost we have in mind. That means that we do not really understand what are the capacities of the company (for example, capacities of the plants, the subcontractors, the teams…)

And of course, another category of wastes is the way we are delivering our products–our internal processes-and all the bad ways of working that we force on the teams (for example stupid decisions, bad tools, excessive bureaucracy, big batches…)

To summarise, we could say “first, do the right thing, then do it right!”. Or, to quote Peter Drucker, “there is nothing so useless as doing efficiently that which should not be done at all”.

So, do the right thing, then do it right: can we imagine doing this by just taking care of our production plants? No way. Above all, Lean seeks to develop in all people the ability to understand what is valuable to customers, and how they participate in this value creation. It starts very early in the product life cycle. Before even starting developments, every effort must be made to understand customer value. And then, throughout the product life cycle, every effort is made to do it right and to ensure at all times that customer value is always the first concern. This also includes the end of the product’s life and its recycling.

We are well aware that the impact of decisions made during the product engineering phase is extremely significant throughout all the subsequent phases. How can you simply produce a product that has not been designed at the same time as its manufacturing process? How can you simply repair and maintain equipment that has not been designed for this purpose? How can we manage the unexpected costs of ownership of a product that has only been designed with a view to cutting costs, without taking into account the total cost of use?

But beyond that, who can force the whole company to look at the long term and not only at the year-end result? The boss. Who should think at all times about helping people create more value for customers? The managers. Who should be at the service of those who create value, to simplify their lives? The support functions.

Lean manufacturing is a good way to learn. Because factories are close to customers (they deliver to customers), and because production activities are often easier to understand. But we quickly see the limit if the same principles, customer satisfaction, people development, problem solving and continuous improvement, are not applied to product creation activities. So, yes! Lean is far more than a manufacturing approach. Lean concerns everyone in the company, from the boss to the workers, including engineers and support functions. And Lean applies throughout the entire product’s life cycle.

****************

Rose Heathcote

Rose Heathcote

Wherever you have broken processes, limping systems, unwanted products or services, or just opportunities and a will to improve, Lean thinking can shift how you look after customers, patrons, and patients.

Lucky me to grow up working in my father’s small manufacturing plant in South Africa where I progressed from cleaner to tea girl to admin, and eventually operator. Champing at the bit to study industrial engineering, Dad thought this wasn’t the best fit for me but, to his credit, he supported and plowed me with second-hand books to fuel the enthusiasm. Heading back a few years later to the factory for an internship, I immersed myself in 5S improvements, time and method studies and layout changes. The plant supplied the automotive sector so it was a fabulous playground to learn people and process and to put some early-stage Lean learning into practice – albeit with limited scope. Dad didn’t want much changed back then! Those of you in family businesses will appreciate that dynamic.

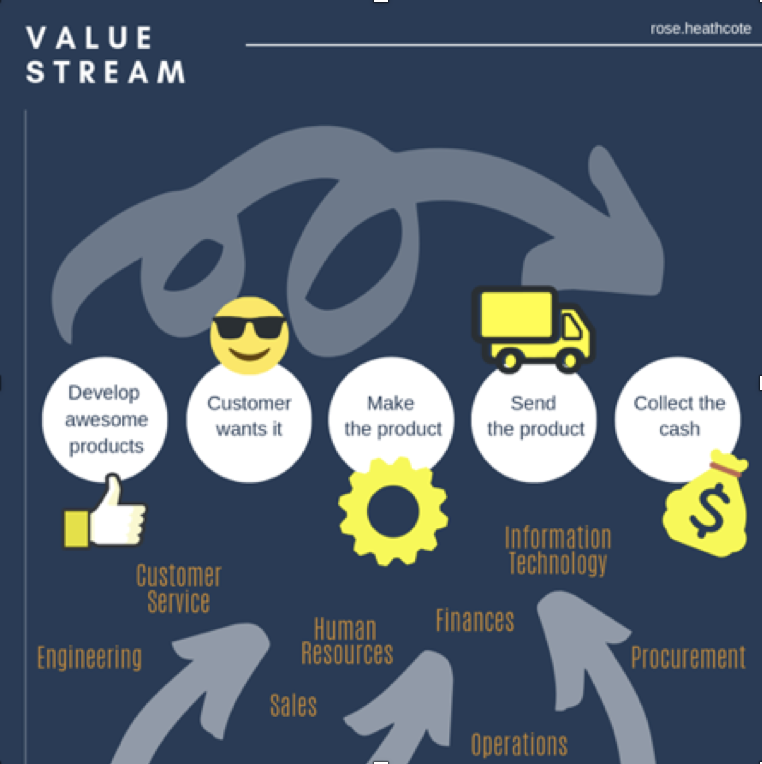

Experiencing Lean in manufacturing is fascinating as you can SEE people and product in action, observe the flows, isolate the quality issues, investigate the visible delays and obvious build-ups that amplify before your eyes. It doesn’t however take long to appreciate that what happens in the non-manufacturing departments influences how well manufacturing ticks over and limiting improvement focus to where products are made tackles a portion of the pie – an opportunity for whole-value stream improvement is lost when we ignore the other just-as-important activities, such as:

- Design of products that customers actually want to buy

- Quick response to customer queries, orders and dealing with issues swiftly

- Procurement of the right materials, at the right price, in the right quantities, at the right time

- Timeous payment of suppliers and nurturing of partner relationships

- Invoices and getting the cash in the bank

- Putting the right bums in seats and developing their skills to deliver great service or superb products, consistently

- Maintenance of equipment, servers, systems to enable fit-for-purpose availability

- …the list goes on… every department counts.

You get more bang for your buck developing Lean thinkers from the cleaner to the CEO. When everyone is solving important problems in their space and you hit a tipping point of experiments churning in every department, the potential unfolds beautifully. This doesn’t just apply to widget makers or manufacturers. Wherever you have broken processes, limping systems, unwanted products or services, or just opportunities and a will to improve, Lean thinking can shift how you look after customers, patrons and patients; the products and services you provide; how you adapt to future conditions; and how you survive competition and economic turbulence. Any kind of organisation has an equal opportunity to connect sensible strategy with action on the ground. I echo what Lucy says in her article – just browse the case studies out there and you’ll see examples of Lean in action in just about every sector…education, financial services, healthcare, construction, veterinary, hospitality, government…it’s far more than just a manufacturing thing. Yes, Lean took root in the automotive sector, but dig deeper and you will see how it permeates every function and beyond into the supply chain. It’s a way of thinking and acting that anyone can capitalise on when they roll up their sleeves and get stuck in.

Chatting to some younger employees at a local automotive manufacturer a few weeks ago, I enjoyed hearing about their A3’s in legal and human resources – following cycles of PDCA (Plan, Do, Check, Act) to aid a culture for continuous improvement. Some of the newest recruits were frustrated by this learning approach that slowed them down, but they knew they would only get a green light for fresh ideas once they had done the work of the A3 and delivered a sound thought-process to their managers. So, they gave it their best. In time, I know they’ll move past the initial frustration and the value of this thinking will be revealed in the results they achieve and the personal learning they experience. They get this is not just for manufacturing but a whole-company and partner approach, and that they need to slow down before they speed up.

A few days after that, I spent time with employees from various functions in the ICT sector. Innovation, digital marketing, human resources, audit, legal and finance to name a few. I am always struck by the nature of the challenges people deal with.

“In our company, it feels as though no one is thinking about customer experience. Everyone just worries about their own department, their metrics and what will make their lives easier. Silos, silos everywhere! It’s like we’re working against each other, and this isn’t good for the customer. Or us.” – Head of Department ICT –

Every organisation has its uniqueness, but you do pick up on common issues, and even more interesting is how following the basic principles of Lean wherever you go still counts. They could immediately see the importance of making important problems visible and clearing the window to the process; developing people to deal with the challenges in a structured, unhindered way; delighting customers and repeating the cycle over and over. Perhaps the HOW of doing this will vary to suit the platform, but the bare bones have a similar makeup.

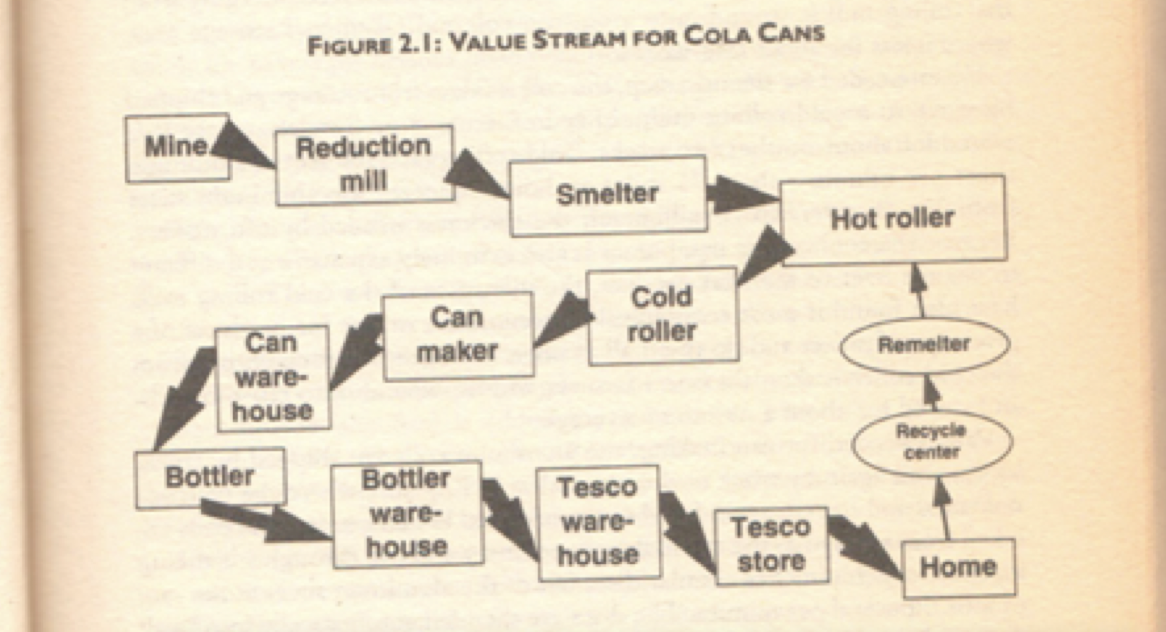

I believe it’s possible to make a difference in Africa, one Lean transformation at a time, in any organisation contributing to the economy. Around 18 years ago I saw this eye-opening visual in the book Lean Thinking (Womack and Jones, 1996, pg 39) which over the years I’ve learned to fully appreciate:

This figure helped me see there is way more to Lean thinking than targeting a single process or seeing just one organisation in the mix. I think there is still value in targeting single (yet critical) processes and improving the one organisation, but this blew my mind open to the idea that this could work across borders, with any supporting service and that seeing the whole picture reveals scope for a profound transformation and a much greater benefit to employees and customers. From pulling resources from the ground all the way to placing product into end-user hands, to recycling – imagine all that’s involved and how many organisations, service providers, processes, systems and people touch this value chain. The possibilities for change extend well beyond manufacturing and that’s exciting.

********************************

Jean Cunningham

Jean Cunningham

I found in every company that the basic TPS/Lean concepts and tools apply. And, when understood and used correctly, will create much better work and outcomes.

While I was the CFO of a custom equipment manufacturing company, we launched an effort to apply TPS to the shop floor. And if you have read Lean Thinking, you already know of the amazing success we had learning and applying pull, small batch, flow and value streams. I was knee deep in those activities, and in my opinion, the CFO must be deep into the lean activities from the very start in order to have long term success for the overall company. After about a year, the lead time on our main products had dropped from a 6-week production lead time to just 15 hours! Truly amazing outcomes, and beyond any of our wildest dreams at the outset. But as CFO, I knew that the time to enter an order from a customer still had a lead time of 2 weeks! That would not work with a 15-hour manufacturing cycle and certainly was not acceptable after I had seen firsthand the amazing transformation in the factory using TPS/Lean tools. What to do?

Initially we thought maybe we needed a new IT system. Ours was really basic an