In this LEI webinar video clip, Eric Ethington and Matt Zayko, coauthors of the new book The Power of Process, share why improving process design pays off in better business results. Find a lightly edited transcript below.

Eric: What I’d like to do is jump right into Why this book? I’ll start with the Yogi Berra quote: “It’s like déjà vu all over again.” The actual story, the experience, of Matt and I is that we realized that what we’ve seen in a lot of different organizations wasn’t unique to us.

What the story involves is: in comes a new process that’s supposed to bring all this greatness with it. And it brings in not only new problems but problems that have been solved long ago. And that becomes demotivating for all the folks in an organization. In our case, it was manufacturing, and this new line that came in had problems that the continuous improvement people had solved on the existing equipment. And here it comes back again to be solved once again–this becomes this never-ending cycle that’s demotivating on spending time, money, and resources trying to fix these things. So what we started thinking about is, “Boy, how do you break this, what we would call a rework cycle?”

Interestingly enough, [LEI Founder and Senior Advisor] Jim Womack, way back in 2008, wrote an article that touched on the topic of Touzen versus Kaizen. Touzen is essentially this rework; it’s kaizen that shouldn’t have been done in the first place. And, although there’s a lot of very motivated, smart, creative folks in the world, ourselves included, that we’re doing lots of kaizen activity, a good portion of that could be categorized as kaizen that we should have never had to do in the first place. We were just fixing stuff that could have been avoided.

Matt: So, the key thing to think about as we go through this, developing a new process with a new product, is, What is the right learning at the right time? So how do you balance the limited resources that you’re going to have when you’re developing a new product — or where you could be scrambling to launch an older or a product that just recently launched. You want to think a year or two years ahead for the next one. How do you balance this out to do the right resources at the right time? So with this, that’s the challenge that we discover with the 6CON Model.

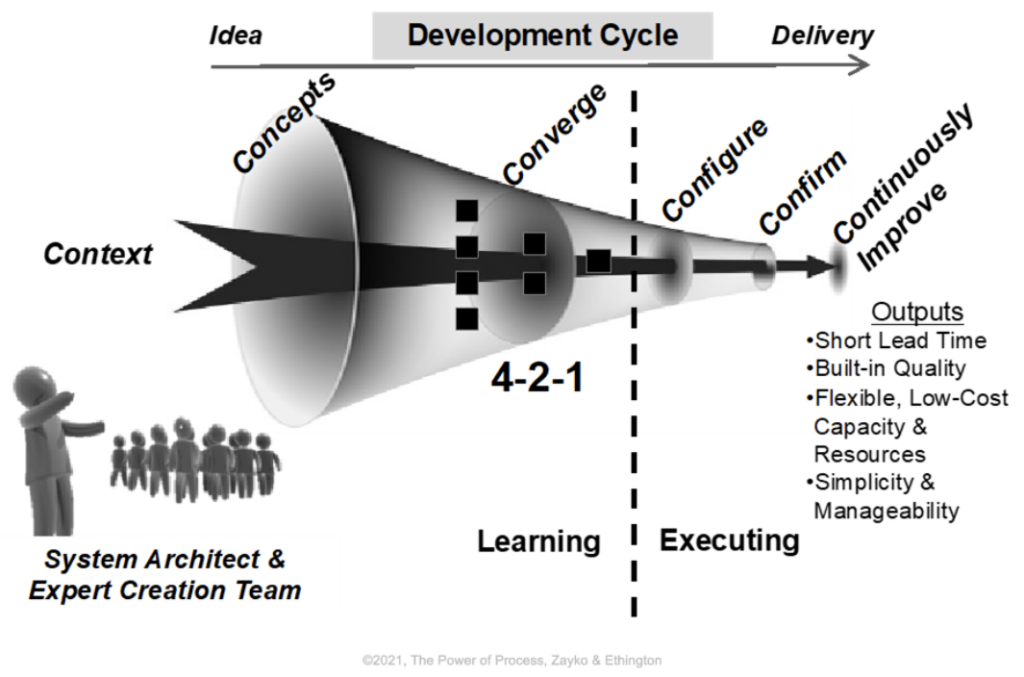

So how this model, the 6CON relates to time: This is a pretty good image to show this. If you think, left to right here at the top, think of the idea stage through delivery. How this works is we’ve got the context is upfront [at left], all the inputs that we need. (I’ll go through again, each of the 6CONS), but from left to right over time, we’ve got the idea and the delivery. At the bottom, we’ve got learning and executing.

So the key thing with this is to think of early on in any new project that we’ve got a lot of learning — knowledge gaps we need to close. So we have the 6CON model and how [the development process] relates to these contexts, concepts, and converge phases.

Then, as you get to a point where you need to start executing and configuring, that’s where the configure stage happens, and then we need to confirm it. Then obviously, there’s the kaizen or continuously improve.

So again, the hypothesis that Eric and I were testing based on Jim Womack’s 2008 article was, he introduced this concept of touzen — T-O-U-Z-E-N. And his premise was a lot of kaizen out there is really just rework of systems that aren’t designed right.

So the challenge is: What is the process that we need to go through to avoid that [rework], and that is what the model is supposed to represent.

And the output, again, whether we’re looking at a business process of financial services, healthcare, manufacturing, you know, we want short lead time, built-in quality, flexible, low costs, capacity resources, and simple and manageable system at the end of the day. So this is how it works in relation to time.

Designing the Future

An Introduction to Lean Product and Process Development.

Well done on the book. This is a strong compliment to many works focused on product development. Concurrent work while the product aspect is still malleable is an underappreciated asset while engineering the value stream. Thank you for your efforts in writing this book and sharing your knowledge and expertise.