Most people who know at least a little about lean know about hoshin kanri (aka strategy deployment) and A3 problem-solving. But even those who know a lot about lean may not fully appreciate how these two lean practices should work together.

In 2014, I wrote “A Body Needs a Skeleton and Muscle to Work,” which described the fundamental thinking behind the linkage of hoshin kanri and A3 problem-solving. In that post, I compared an organization to a human body. If we think of an organization like a human body, the management system represents the skeleton that holds the organization’s structure together. And A3 problem-solving functions like the muscle to generate movement and action. Problem-solving capability in an organization gets stronger through practice just as our muscles get stronger through exercise.

An organization that integrates daily problem-solving with a robust long-term-oriented management system yields greater performance gains than an organization with only one or the other, or when the two practices are not linked. The relationship between the management system and problem-solving methods—particularly the linkage between the two—is crucial to optimize organizational effectiveness. Combined, the two practices improve how an organization:

- Plans what it does.

- Executes on those plans.

- Continuously improves.

Daily Management and Practical Problem-Solving

Most organizations, whether a manufacturer, builder, restaurant chain, hospital, or whatever, must manage on two time horizons — daily and mid-long term. To handle both simultaneously requires that you have both a daily management system and a strategic planning system. Likewise, each system needs a corresponding problem-solving methodology and toolset to address issues that arise.

For example, if an assembly line is having difficulty meeting its daily output goals, operators will work to fix the problem immediately, within the hour, or at most within the day. This type of problem-solving is called Troubleshooting or Type 1 problem-solving by Art Smalley, in his book Four Types of Problems.

In lean operations, Type 1 problem-solving, which helps achieve stability, is enabled by establishing clear standards that allow operators to address a deviation from standard quickly or to improve based on the standard continuously. The practice works exceptionally well in any operation that is repeatable (and much is repeatable though so many companies think they are unique and their work is non-repeatable).

The root cause of this same problem, not meeting daily output, however, may also be a structural issue. For example, if we look across the assembly line and realize that a shortage of Team Members causes our output problem—we need 500 people a day on the line but are only able to consistently staff 470—that’s a problem that must be addressed using a longer-range problem-solving method.

Further, if the root cause cannot be resolved through daily management and problem-solving, it’s a strategic business problem. This type of issue likely is caused by one or more structural issues and may result in losing business to competitors. Several years ago, I worked closely with an appliance manufacturer where this issue occurred. Unable to meet customer demand, it lost floor space at Home Depot, which set them back significantly against their competitors. This type of problem cannot be handled purely through daily management and problem-solving.

The Relationship of Hoshin Kanri and A3 Problem-Solving

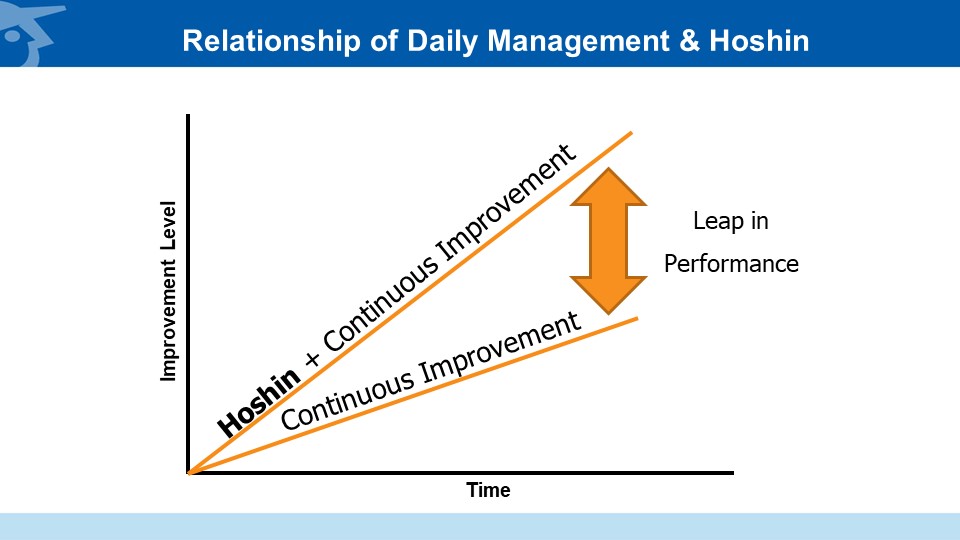

Combining hoshin and continuous improvement through A3 problem-solving results in better performance gains greater than either practice deployed alone.

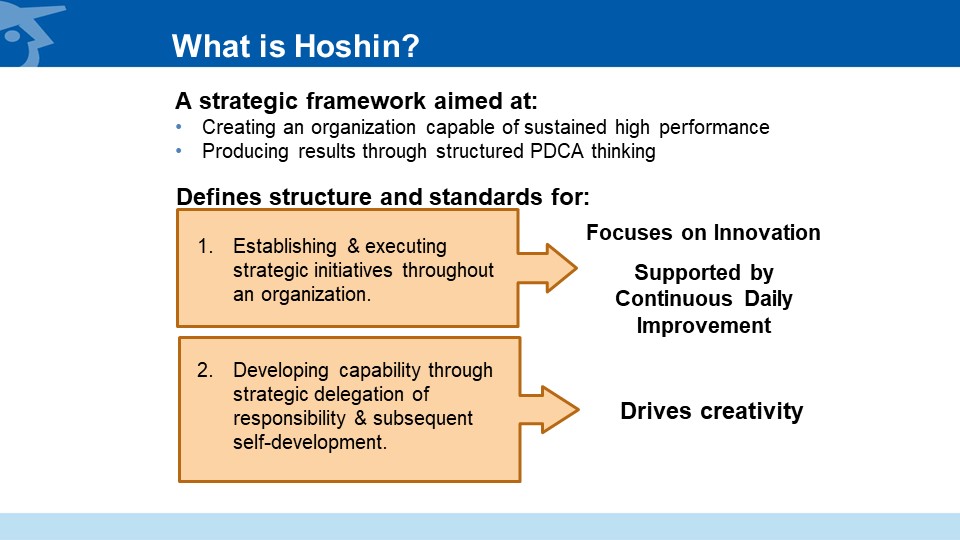

Based on what I learned at Toyota, I define hoshin kanri as problem-solving at the strategic, structural level — it focuses on innovation and drives creativity.

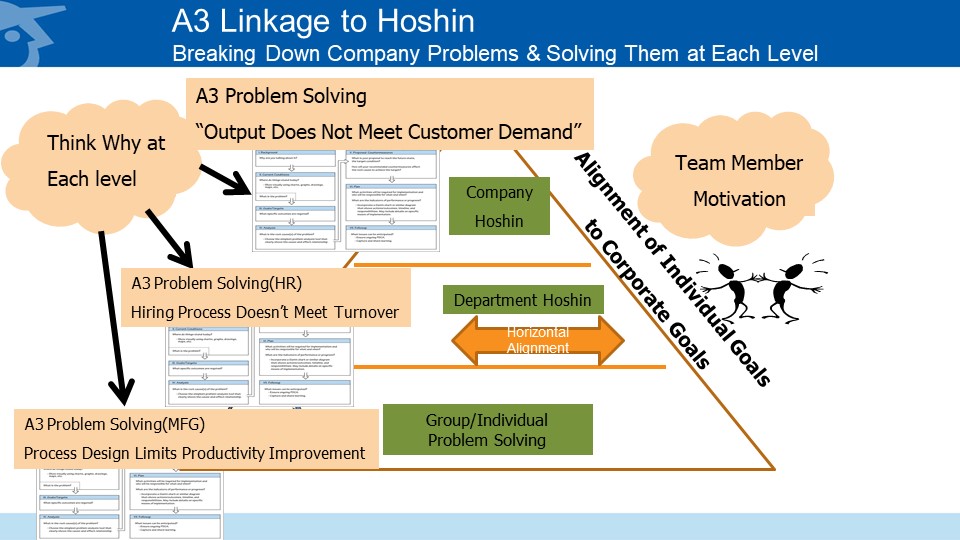

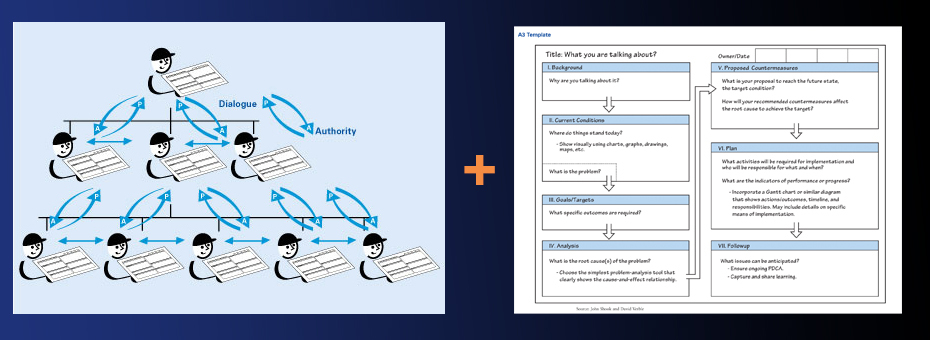

Hoshin kanri is a system that engages everyone in the organization not merely as problem-solvers, but also as innovators. Built on top-down and bottom-up idea generation system, hoshin kanri pushes the organization to a higher competitive level based on innovative thinking across the organization. I often show this graphic to represent the essential thinking:

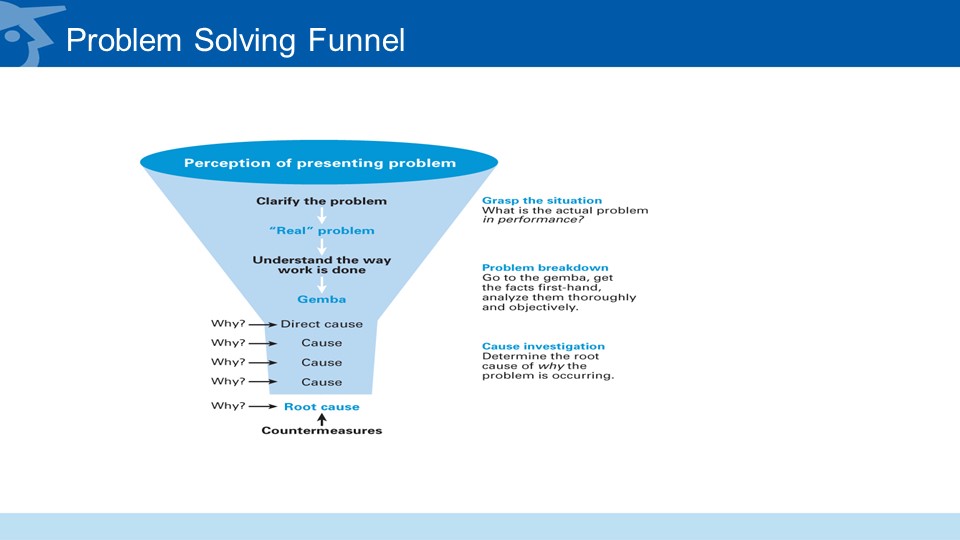

So how does A3 problem-solving fit in? If we think about the issue discussed earlier, of missed production goals caused by a workforce shortage, you can imagine many possible root causes. The problem could be caused by wages, working conditions, the general labor market, the culture in the production plant, management issues, the level of automation, or many other reasons. It’s also possible that the problem is not unique to this plant, but something that all the company’s plants are experiencing. Operators cannot solve issues such as this by troubleshooting.

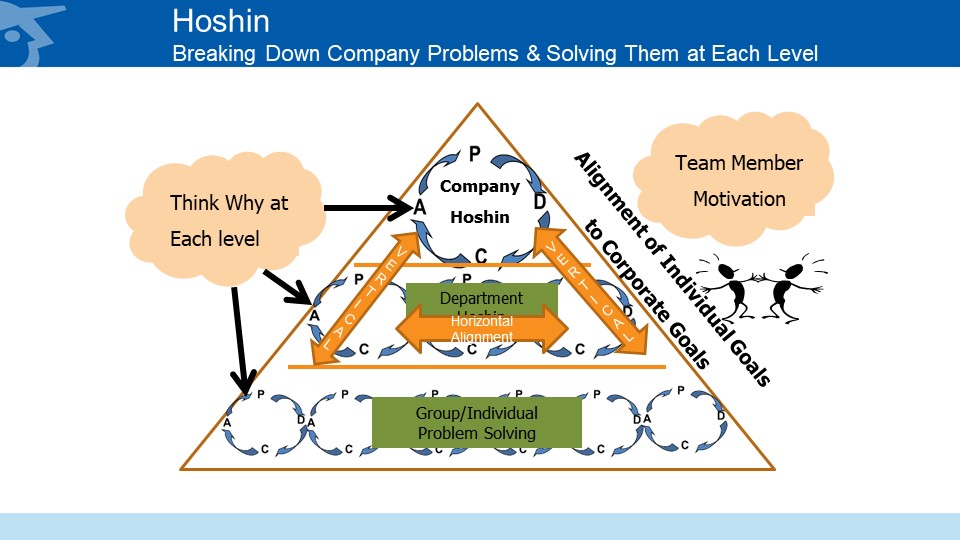

To solve a structural problem such as this, you need a problem-solving method that prioritizes and resources this issue at the corporate level and in alignment with many parts of the organization, including manufacturing, engineering, human resources, finance, or other departments. The best method is to have A3 problem-solving embedded within your hoshin kanri plan. With A3 tightly linked to hoshin, an organization will not only solve problems but also will have the opportunity to innovate new ways of operating throughout the business.

Toyota tackled problems with missed production over the last twenty years by building its A3 problem-solving muscle within the structural skeleton of its hoshin. This approach allowed Toyota to innovate how to manufacture vehicles by reducing the work’s difficulty, not the number of people needed to do it. Its innovations enabled a broader range of people to complete work tasks more efficiently. While at Toyota, I probably wrote or coached about 500 A3s, and they were predominately used to address problems derived from hoshin priorities at the corporate or functional level.

Problem-Solving = Innovation

Linking A3 problem-solving with hoshin ensures companies engage people throughout the organization to solve corporate-level or organization-wide problems.

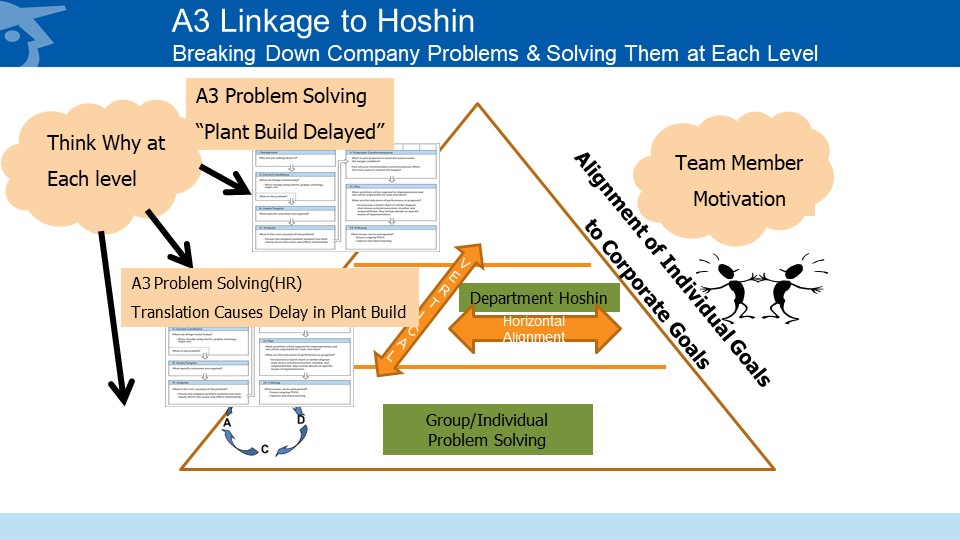

In John Shook’s book Managing to Learn, the protagonist, Desi Porter, is assigned a problem to solve related to document translation quality and speed. While his task starts as a seemingly simple problem, he discovers that it is quite complicated and that solving it will require the involvement of engineers, vendors, and other parties.

Further, Desi can clearly see how his A3 links to and supports the higher-level hoshin objective — launching a new production plant on time — that Ken Sanderson, his boss, is working to achieve.

Ultimately, hoshin and A3 problem-solving are symbiotic. Like our skeleton and muscle, one does not work as effectively without the other. Hoshin kanri is needed to define and gain alignment on critical strategies across the organization, while A3 is used to solve the problems discovered in executing those strategies.

Managing a Lean Enterprise

Learn how to drive performance and inspire innovation using hoshin kanri, daily management, and A3 process.

Is there a new modified online tool or App for the A3 instead of using the classic A3 in excel sheet format?

Hi Osama — thank you for the question. I’ve found the most success with just pencil and paper or note taking apps like GoodNotes and Notability on iPad. Both offer the simplicity of writing by hand with lots of handy flexibility.